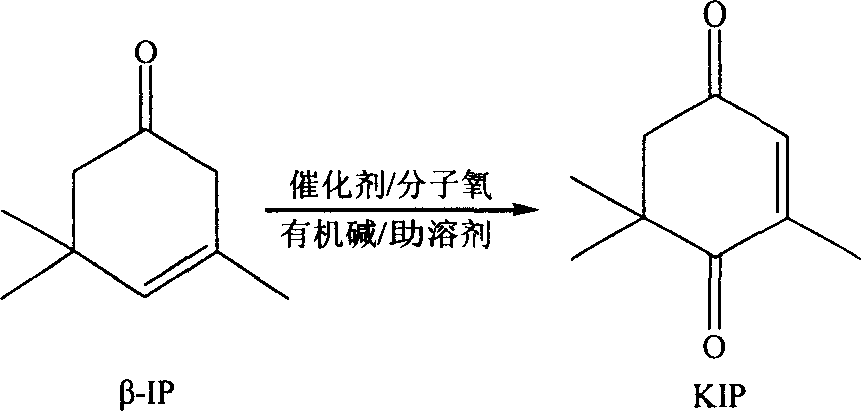

Process for preparing ketoisophorone

A technology for oxoisophorone and isophorone, which is applied in the field of preparation of oxoisophorone, can solve the problems of high process cost, easily destroyed catalyst, decreased reaction selectivity and the like, and achieves good reaction selectivity. , The effect of high reaction conversion rate and less catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.1g of catalyst (1#), dissolve it with 5ml of co-solvent DMF, and add it into a 250ml four-necked flask. Then add 50g of β-isophorone and 10ml of THF successively, and in a water bath at 80°C, feed oxygen while vigorously stirring. After 4 hours, the reaction is complete, the conversion rate is above 98%, and the selectivity reaches 88.5%.

Embodiment 2

[0033] Weigh 0.25g of the catalyst (2#), dissolve it with 5ml of co-solvent DMF and add it into a 250ml four-necked bottle. Then add 50g of β-isophorone and 10ml of pyridine successively, in a water bath at 40°C, feed oxygen, and stir vigorously at the same time, after 15 hours, the reaction is complete, the conversion rate is above 98%, and the selectivity reaches 95.5%.

Embodiment 3-10

[0035] Similar to embodiment 1, 2, respectively use the catalyst of different compositions, obtain following result (table one) after reaction finishes:

[0036] implement

example

BIP

(g)

catalyst

(g)

organic base

(ml)

Co-solvent

(ml)

temperature

(℃)

total time

(h)

Conversion rate

(%)

selectivity

(%)

3

50

3#0.10

Ethylenediamine 10

Methanol 5

80

8.5

92.5

55.6

4

50

4#0.10

Triethylamine 10

THF 5

80

7

94.5

72.5

5

50

5#0.10

Pyridine 10

DMF 5

80

4

98.5

85.6

6

50

6#0.10

Ethylenediamine 20

DMSO 5

80

4.5

98

88.1

7

50

7#0.25

Triethylamine 20

Methanol 5

40

14.5

98.8

93.2

8

50

8#0.25

Pyridine 20

THF 5

40

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com