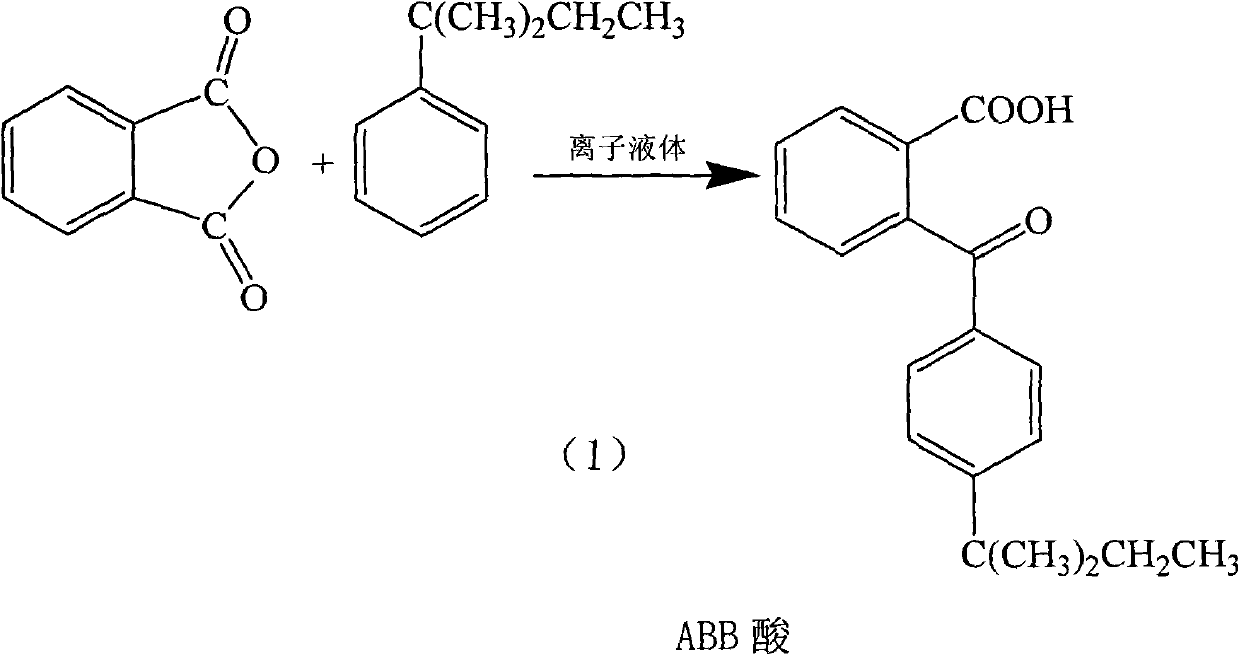

Preparation method of 2-(4'-amyl-benzoyl) benzoic acid

A technology of pentylbenzoyl and benzoic acid, which is applied in the field of preparation of 2-benzoic acid, can solve the problems of environmental pollution, large amount of catalyst consumption, difficult post-processing, etc., and achieve the effect of no three wastes and less catalyst consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The molar ratio of tert-amylbenzene:phthalic anhydride:catalyst is 0.5:1.0:1.0. The catalyst uses chlorinated-1-methyl-3-butylimidazole-aluminum trichloride ionic liquid.

[0020] Into a 250ml three-necked flask equipped with a thermometer and a stirrer, add 5.28g of tert-amylbenzene, 5.29g of phthalic anhydride, and 11.01g of catalyst, blow in nitrogen, start stirring, slowly raise the temperature to 50°C, and react at this temperature for 5h. After the reaction, add water and suction filter to obtain white powdery solid ABB acid with a yield of 62.3% and a purity of 92.0%.

Embodiment 2~16

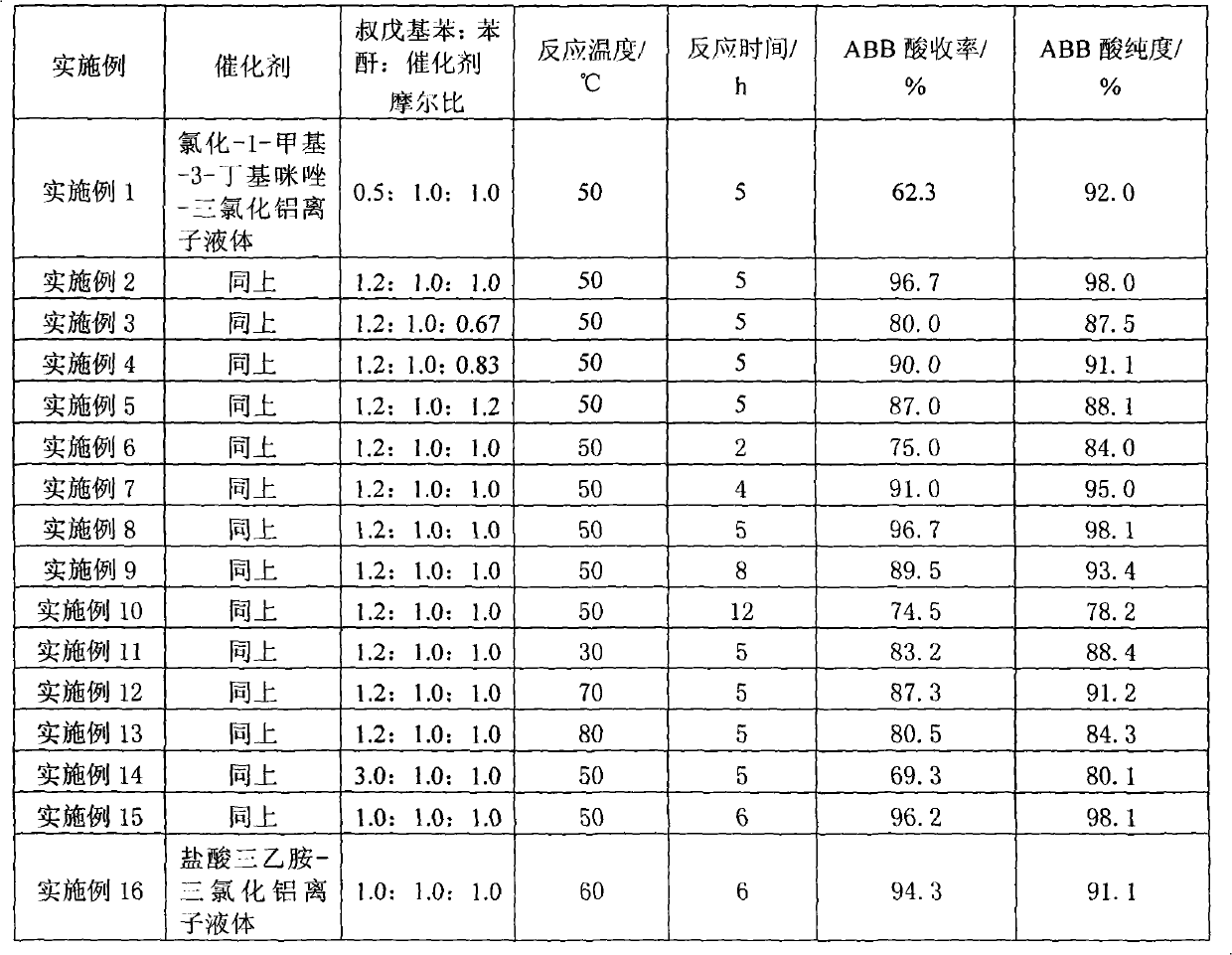

[0022] According to the method of Example 1, experiments under different conditions were carried out, and the variation factors and experimental results of each embodiment are shown in Table 1.

[0023] Table 1 Embodiment 1~16 test conditions and results

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com