Microwave synthesis method used for multi-phase oxidation catalyst of hydrogen phosphide

An oxidation catalyst and microwave synthesis technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low absorption efficiency and slow reaction speed, and achieve Improved absorption efficiency, rapid synthesis, and less catalyst usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

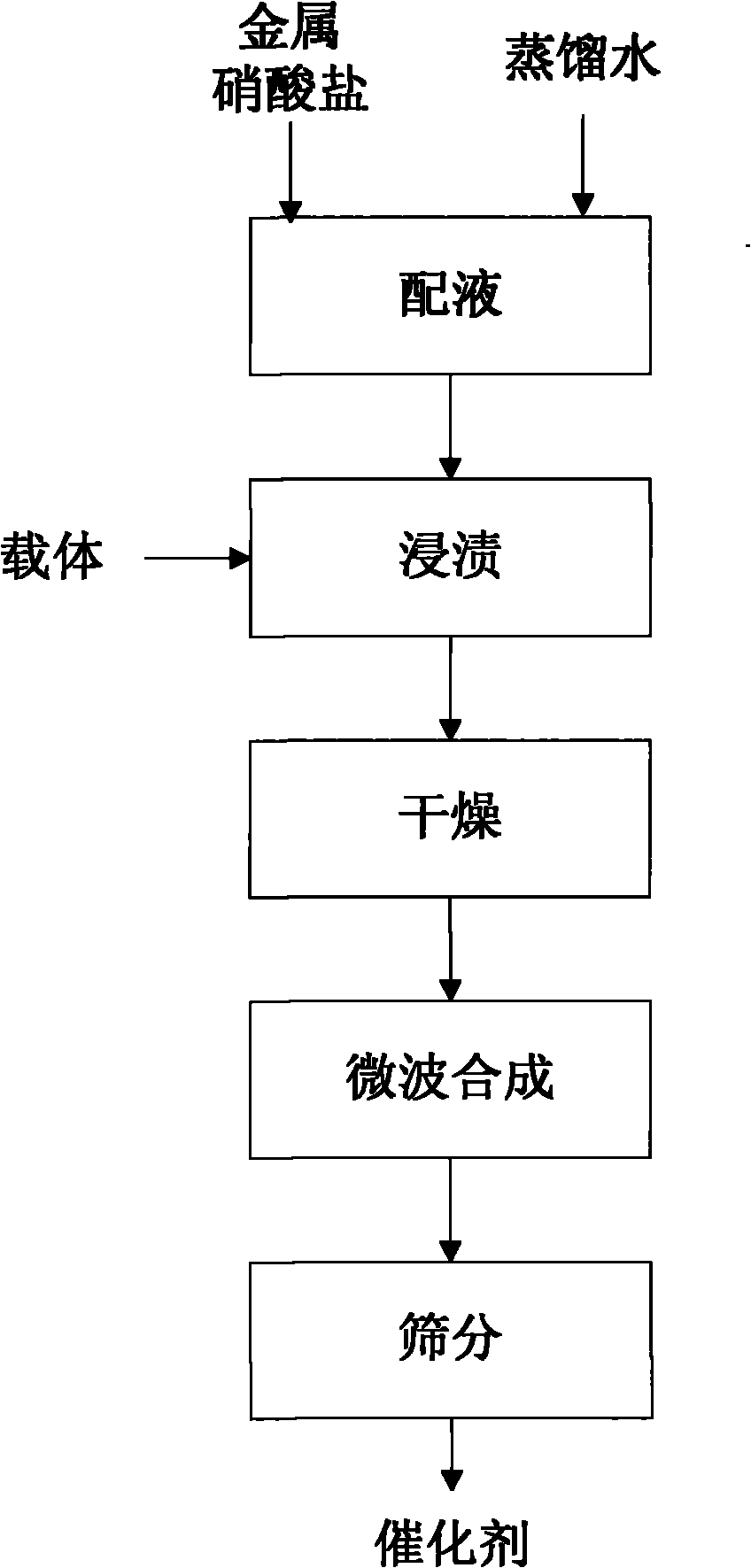

Method used

Image

Examples

example 1

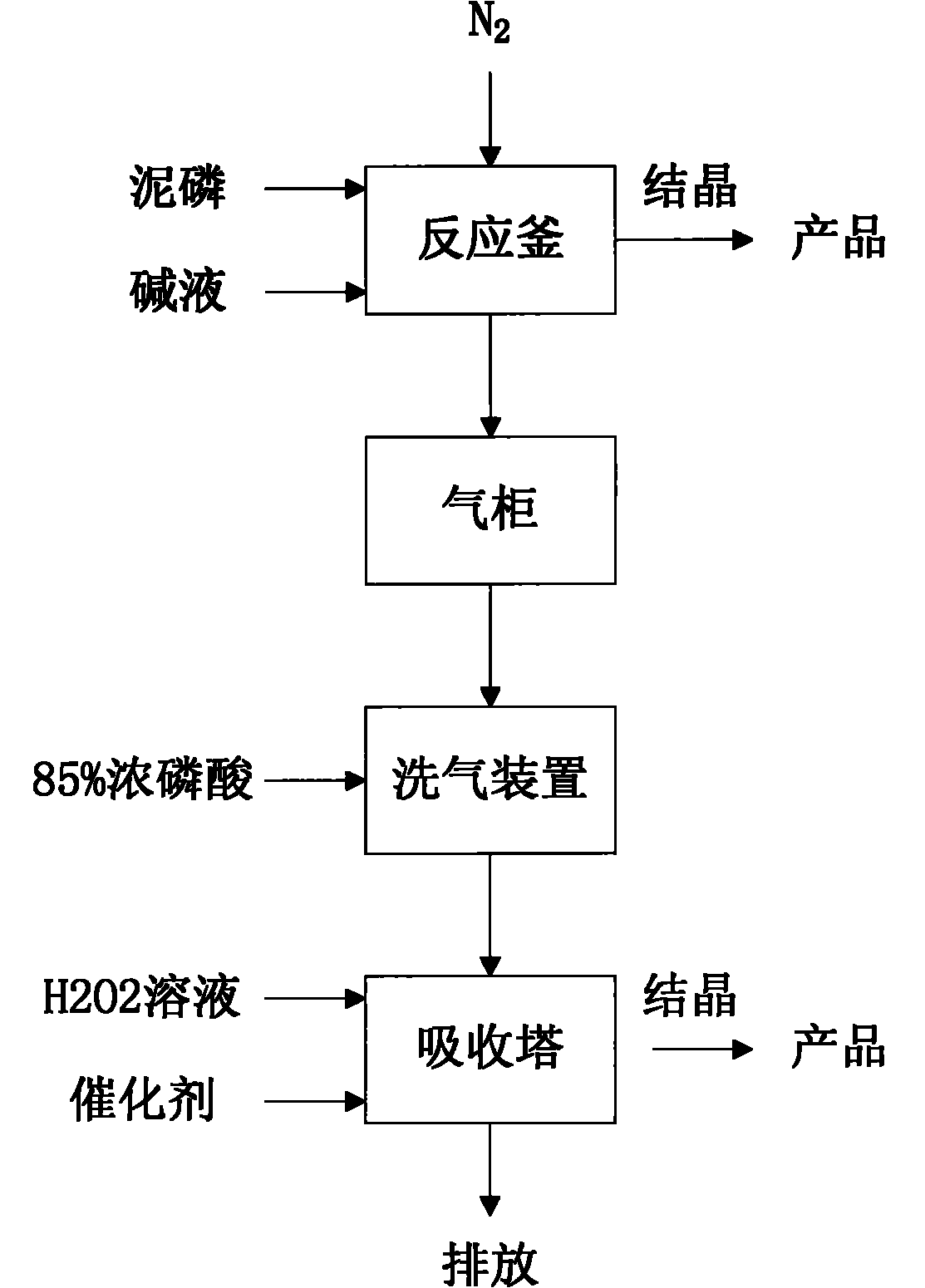

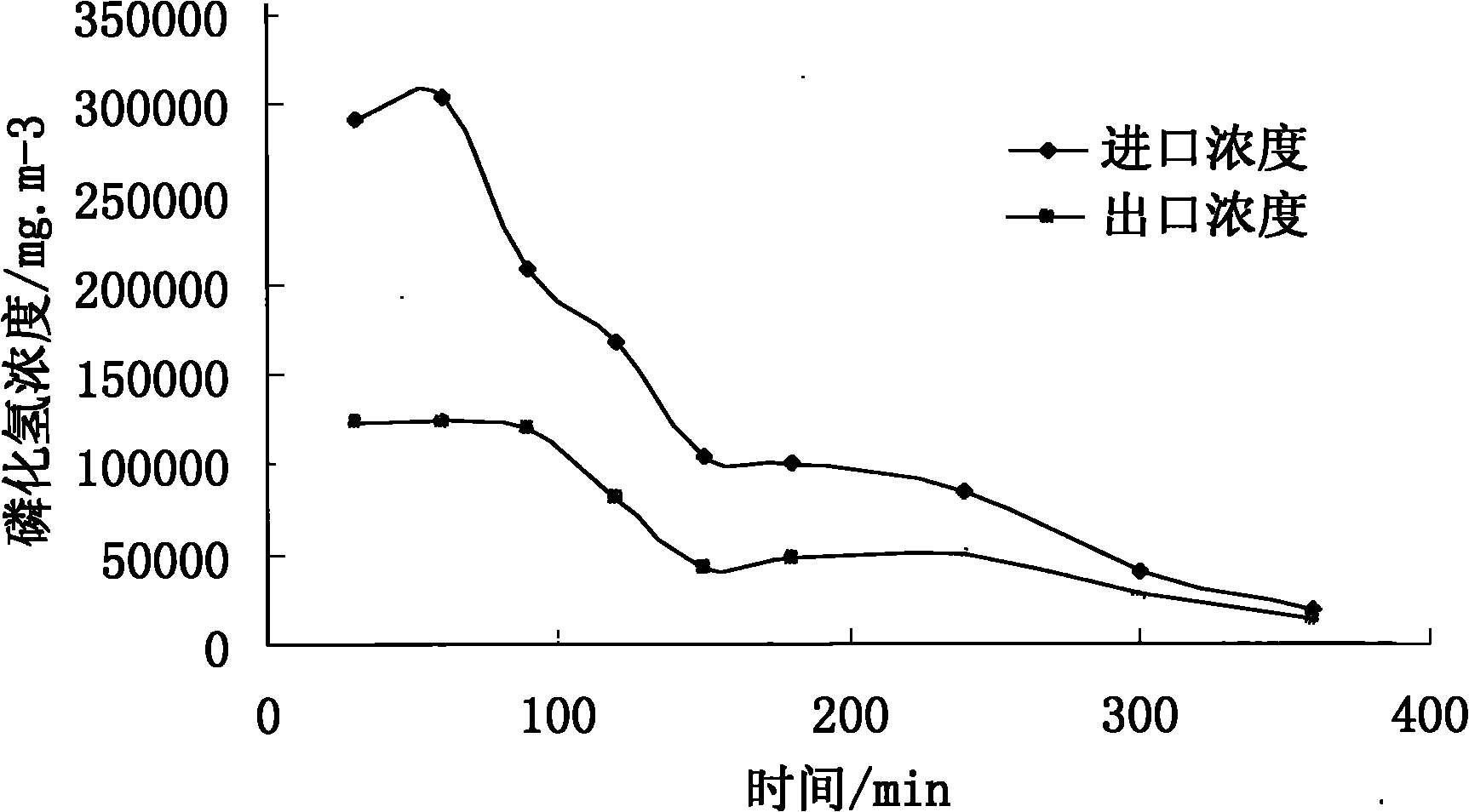

[0020] Example 1: Dissolve cerium nitrate in distilled water to make a solution with a cerium ion concentration of 0.01mol / L; soak 4A zeolite with a particle size of 180 mesh in 0.1mol / L sodium hydroxide solution for 1 hour, after soaking Repeatedly wash with distilled water several times, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water after soaking, and finally soak in distilled water for 1 hour, filter and dry at 105°C for 12 hours; after pretreatment Finally, add it into the prepared solution according to the solid-liquid mass ratio of 1:5, stir at room temperature for more than 4 hours, soak for 20 hours, and then filter; put the dried filter cake in a microwave synthesizer, microwave power 80W, Heated for 30 minutes, and sieved to obtain a 180-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:200. When preparing sodium hypophosphite, the materials of the reactor are 10.0...

example 2

[0022] Example 2: Dissolve ferric nitrate in distilled water to make a solution with an iron ion concentration of 0.5 mol / L; soak diatomite with a particle size of 110 mesh in 0.1 mol / L sodium hydroxide solution for 1 hour, soak After that, wash repeatedly with distilled water several times, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water after soaking, and finally soak in distilled water for 1 hour, filter and dry at 118°C for 12 hours; After treatment, add it into the prepared solution according to the solid-liquid mass ratio of 1:18, stir at room temperature for more than 5 hours, soak for 19 hours, and then filter; put the dried filter cake in a microwave synthesizer with a microwave power of 540W , treated for 18 minutes, and sieved to obtain a 110-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:100. When preparing sodium hypophosphite, the material in the reactor is 9....

example 3

[0025] Example 3: Dissolve copper nitrate in distilled water to make a solution with a copper ion concentration of 1mol / L; soak activated carbon with a particle size of 40 mesh in 0.1mol / L sodium hydroxide solution for 1 hour, and rinse with distilled water after soaking Repeated washing several times, then soaking with 0.1mol / L hydrochloric acid solution for 1 hour, repeated washing with distilled water after soaking, and finally soaking in distilled water for 1 hour, filtering and drying at 130°C for 12 hours; after pretreatment, Put it into the prepared solution according to the solid-liquid mass ratio of 1:30, stir at room temperature for more than 6 hours, soak for 18 hours, and then filter; put the dried filter cake in a microwave synthesizer, microwave power 1000W, and treat for 5 minutes , and sieved to obtain a 40-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:100. When preparing sodium hypophosphite, the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com