System and method for separating and refining xylylene diisocyanate product

A technology of xylylene diisocyanate, separation and purification system, applied in the field of separation, can solve problems such as unmentioned, polymerization side reaction, separation difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

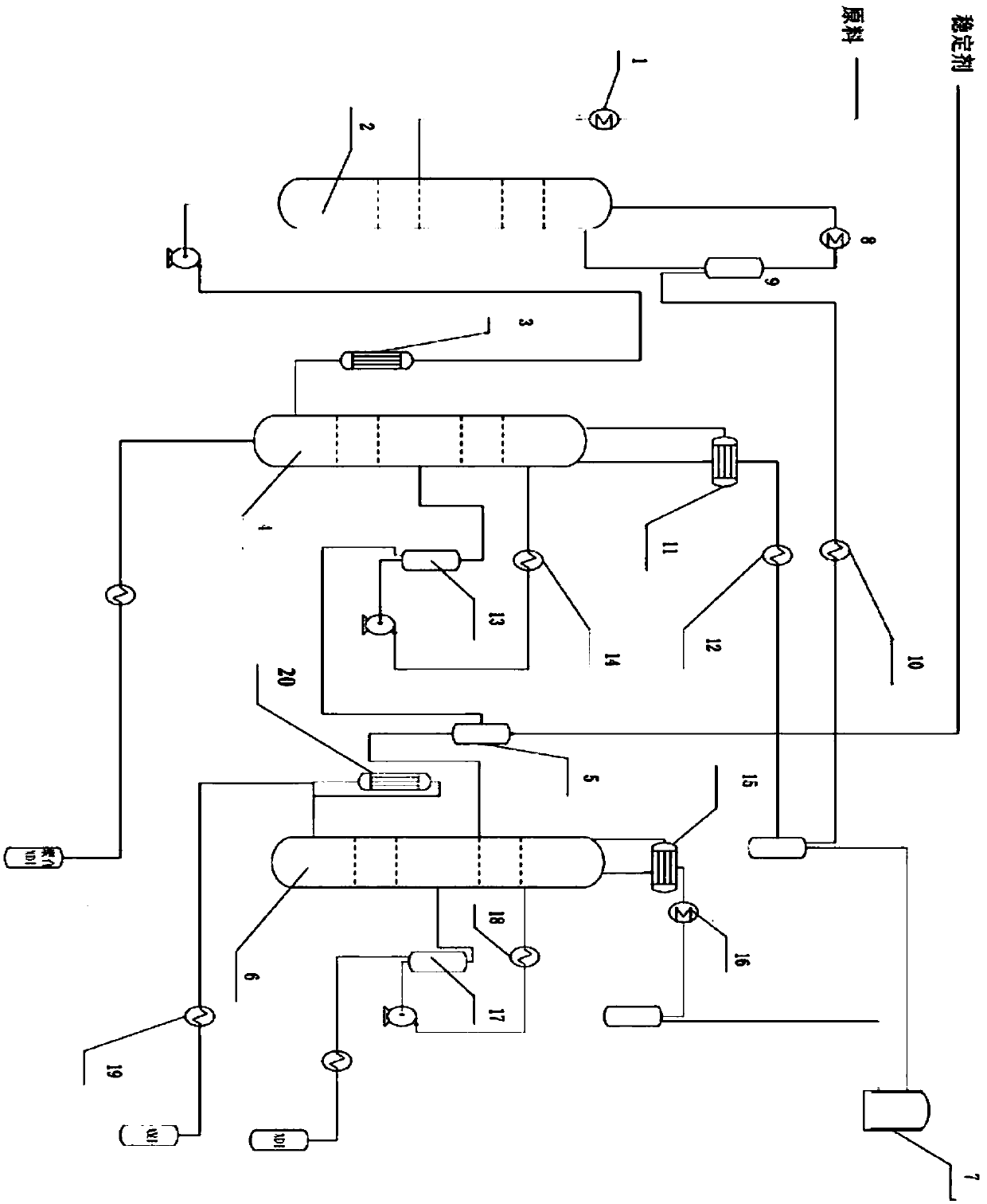

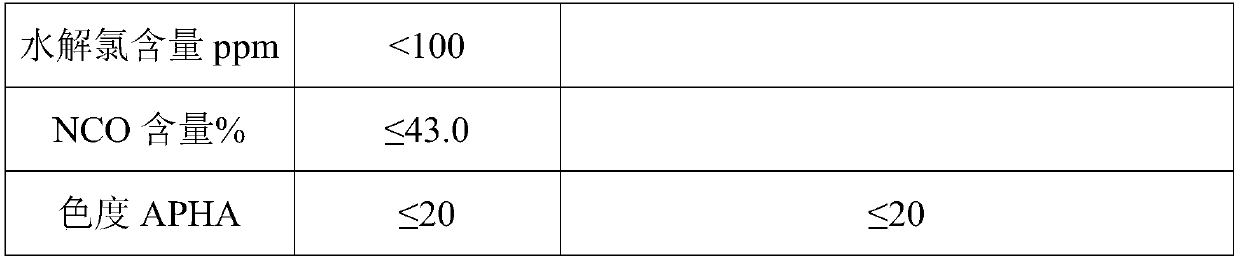

[0086] The present embodiment provides a kind of separation and refining system of xylylene diisocyanate product and processing method thereof, such as figure 1 As shown, the system includes: raw material preheater 1, desolventization tower 2, cooling assembly at the top of desolventization tower, weight removal tower weight removal tower falling film reboiler 3, weight removal tower 4, weight removal tower top Cooling assembly, condensate reflux assembly in the middle of the de-weighting tower, stabilizer mixing device 5, product refining tower 6, cooling assembly at the top of the product refining tower, condensing reflux assembly in the middle of the product refining tower, and vacuum device 7;

[0087]Among them, the raw material to be processed is connected to the feed port in the middle of the desolventization tower 2 through the raw material preheater 1, and the bottom material outlet of the desolventization tower 2 passes through the falling film reboiler 3 of the weigh...

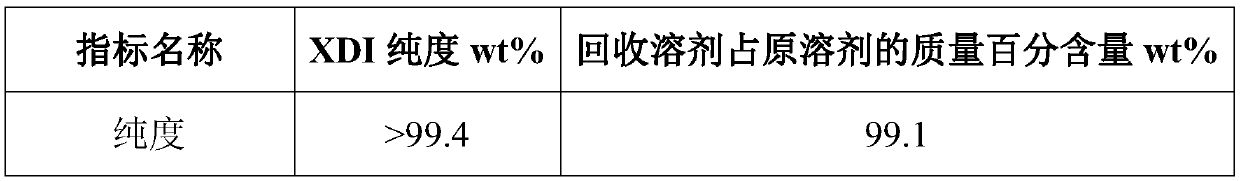

Embodiment 2

[0105] A method for separating and refining the xylylene diisocyanate product of the system described in Embodiment 1, comprising the steps of:

[0106] (1) raw material to be treated (wherein, the massfraction of XDI is 14wt%, the massfraction of polymerization XDI is 2wt%, the massfraction of XMI is 4wt%, the massfraction of solvent is 80wt%) preheating through raw material preheater 1 Enter the desolvation tower 2 that the number of theoretical plates is 20 to carry out desolventization from the position of theoretical plate number 7 afterward, the flow rate of raw material is 95kg / h, the operating pressure of desolvation tower 2 is 20kPa, and tower still operation temperature is 160°C, set the reflux ratio to 1;

[0107] (2) The solvent produced at the top of the desolventization tower 2 will obtain a solvent with a purity of 99wt% after being cooled by the cooling assembly at the top of the desolventization tower. The content is 76wt%, the XMI content is 19wt%, and the X...

Embodiment 3

[0115] A method for separating and refining the xylylene diisocyanate product of the system described in Embodiment 1, comprising the steps of:

[0116] The separation and refining method of the xylylene diisocyanate product comprises the steps:

[0117] (1) The raw material to be processed is preheated to 110°C from the position of the 12th tray and enters a desolventization tower with a theoretical plate number of 30 for desolvation treatment. The flow rate of the raw material is 95kg / h, and the desolventization tower The operating pressure is 50kPa, the operating temperature of the tower kettle is 160°C, and the reflux ratio is set to 5;

[0118] (2) The solvent produced at the top of the desolventizing tower is cooled to obtain a solvent with a purity of 99wt%, and the material produced at the bottom of the tower includes concentrated solutions of XDI, polymerized XDI and XMI, and the solvent mass fraction is ≤ 2wt%;

[0119] (3) The material at the bottom of the desolven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com