Lineating cutting equipment for tablet sugar forming

A technology for cutting equipment and candy chips, applied in metal processing and other directions, can solve problems such as separation, reduce labor intensity, improve production efficiency, and improve product specifications and standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

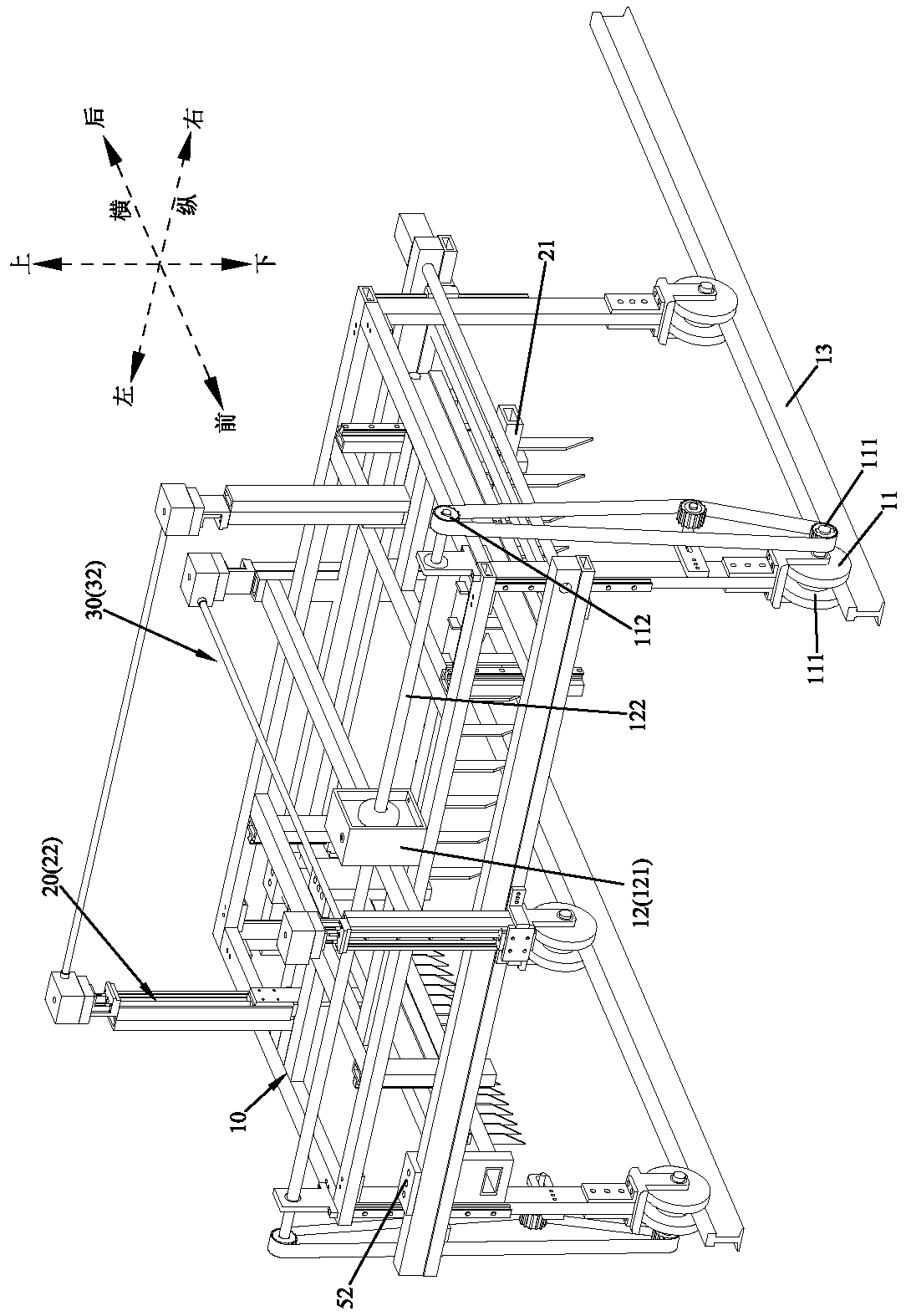

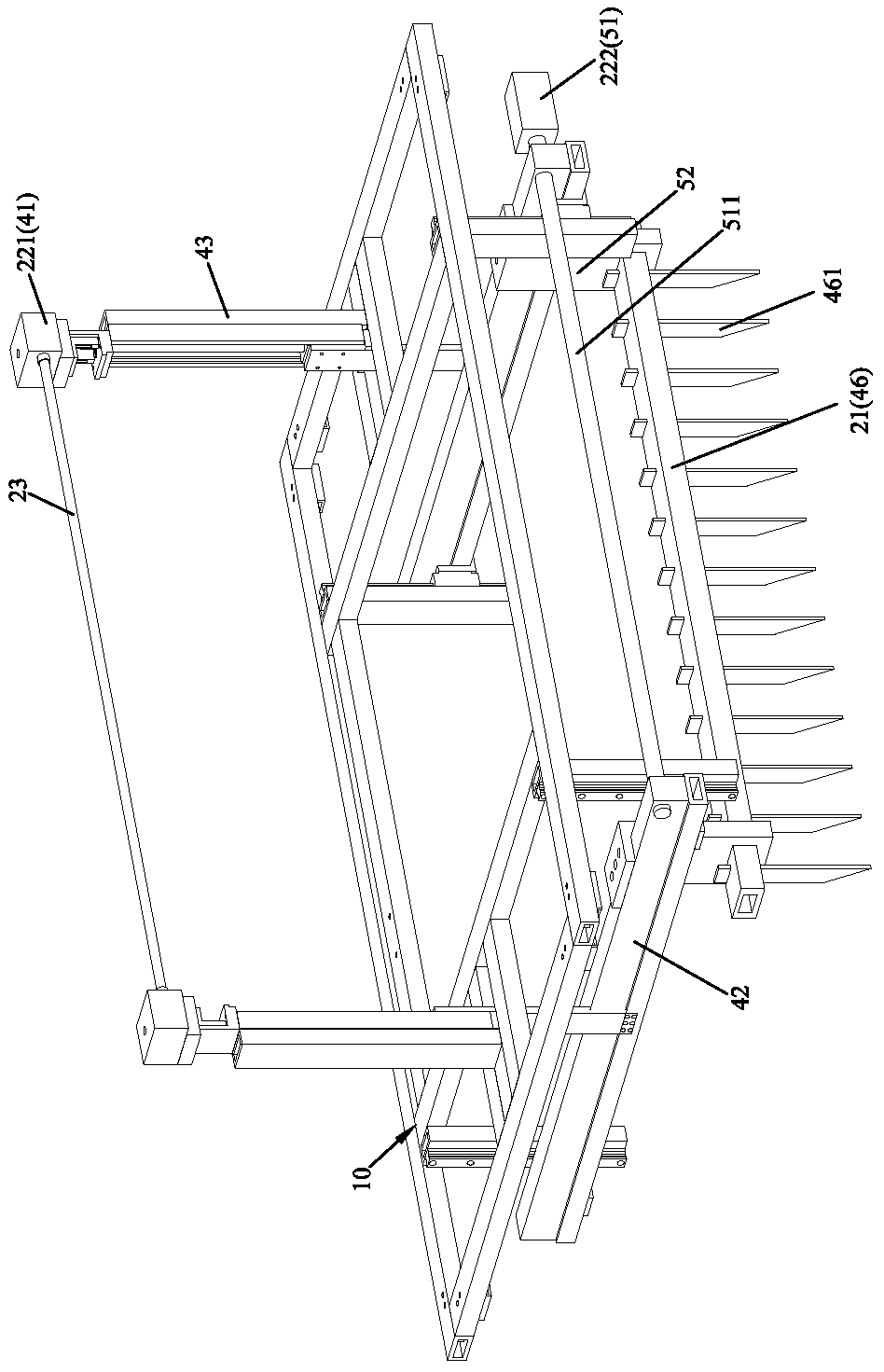

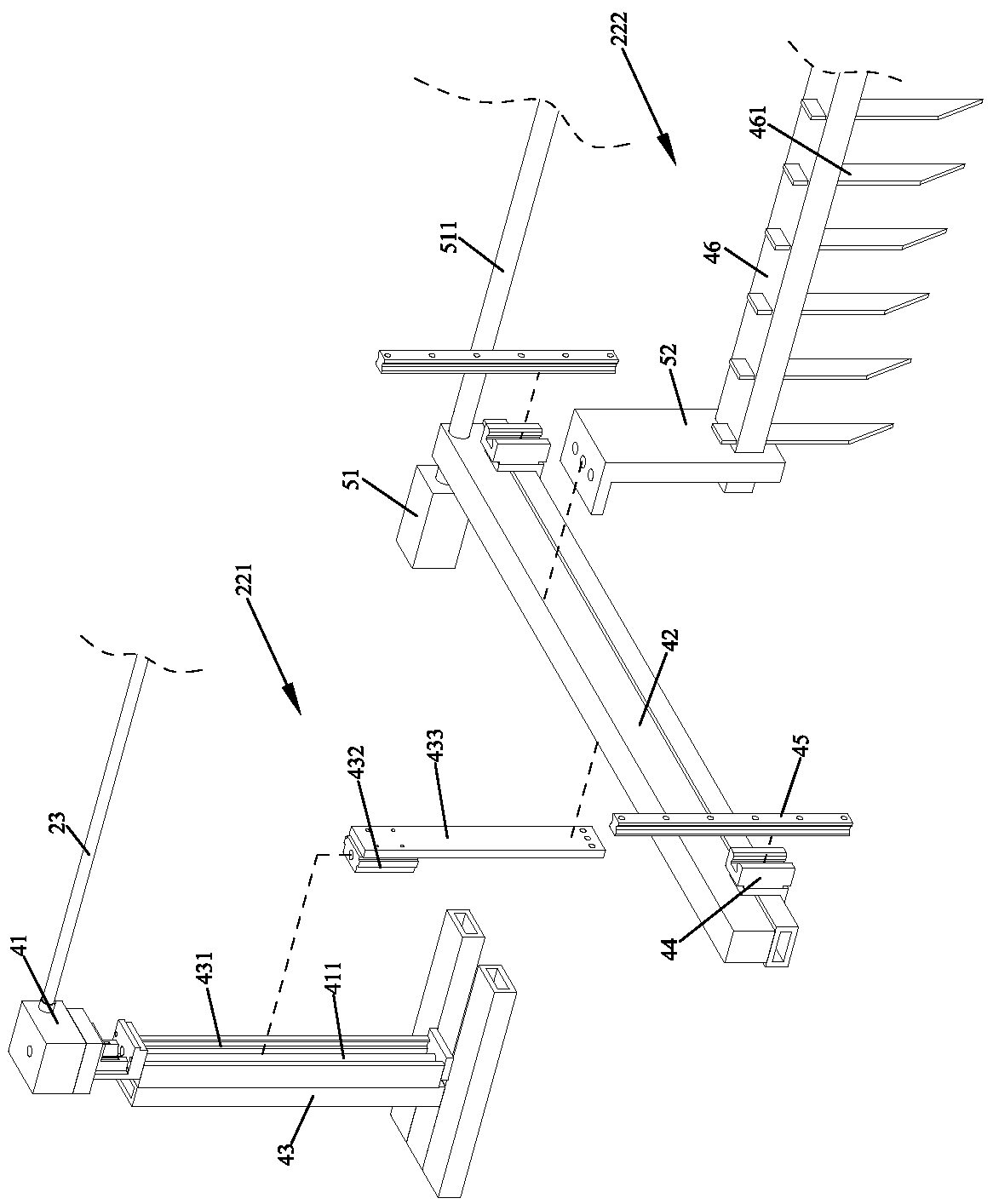

[0042] Please refer to Figure 1 to Figure 4 Shown, it has shown the specific structure of the preferred embodiment of the present invention, it is a kind of sheet sugar forming scoring line cutting equipment that can complete the automatic cutting of sugar blocks on the sugar bed, the equipment includes a frame 10, located on The transverse cutting device 20 and the longitudinal cutting device 30 on the frame 10.

[0043] Wherein, the cross-cutting device 20 includes a cross-cutting tool 21 and a cross-cutting tool driving module 22, the cross-cutting tool 21 is connected to the cross-cutting tool driving module 22, and the cross-cutting tool driving module 22 Drive the cross-cutting tool 21 to move up and down and forward and backward, and cut in the transverse direction of the candy; the slitting device 30 includes a slitting knife 31 and a slitting knife driving module 32, and the slitting knife 31 is connected to the slitting knife. On the knife driving module 32, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com