Automatic nail placing apparatus

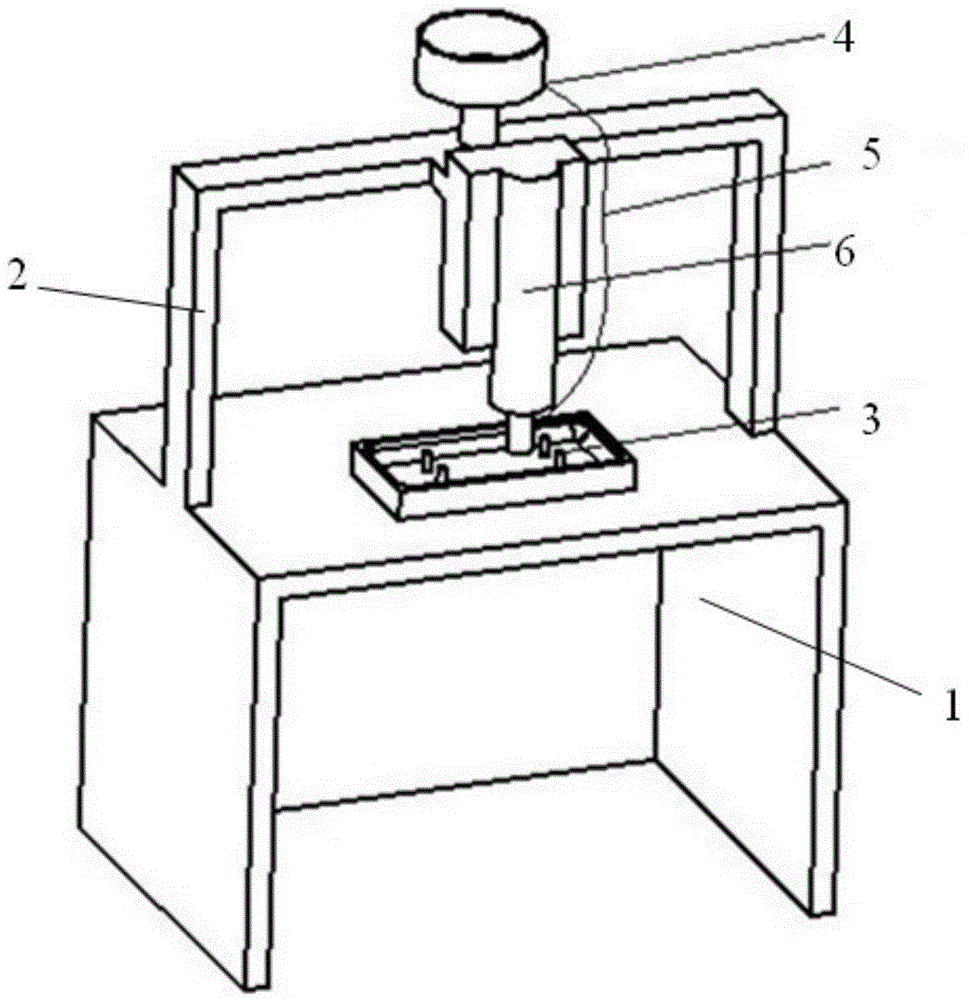

An automatic, vibrating plate technology, applied in the field of plastic product manufacturing, can solve the problems of high work intensity, labor-intensive, slow work speed, etc., and achieve the effects of reducing labor intensity, improving work efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] At present, most factories adopt the method of manual setting of nails, which is slow in operation speed, low in efficiency, and high in work intensity, which is easy to cause fatigue and consumes a lot of manpower, and after long-term work, there will inevitably be work negligence. Nails and other adverse conditions occur, resulting in an increase in the rate of defective products, increasing production costs and other problems and deficiencies.

[0026] The present invention aims at the problems and deficiencies of the prior art. The invention discloses an automatic nail pendulum device, so as to effectively reduce labor intensity and improve work efficiency while realizing nail pendulum automation, and at the same time, avoid accidents caused by negligence. The purpose of producing products and reducing production costs.

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com