Ethylene sulfate preparation method and catalyst thereof

A vinyl sulfate and catalyst technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, catalytic reactions, etc., can solve the problems of difficult purification of final products, high content of chloride ions, and many wastes, and achieve atomic utilization High efficiency, simple process route, less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

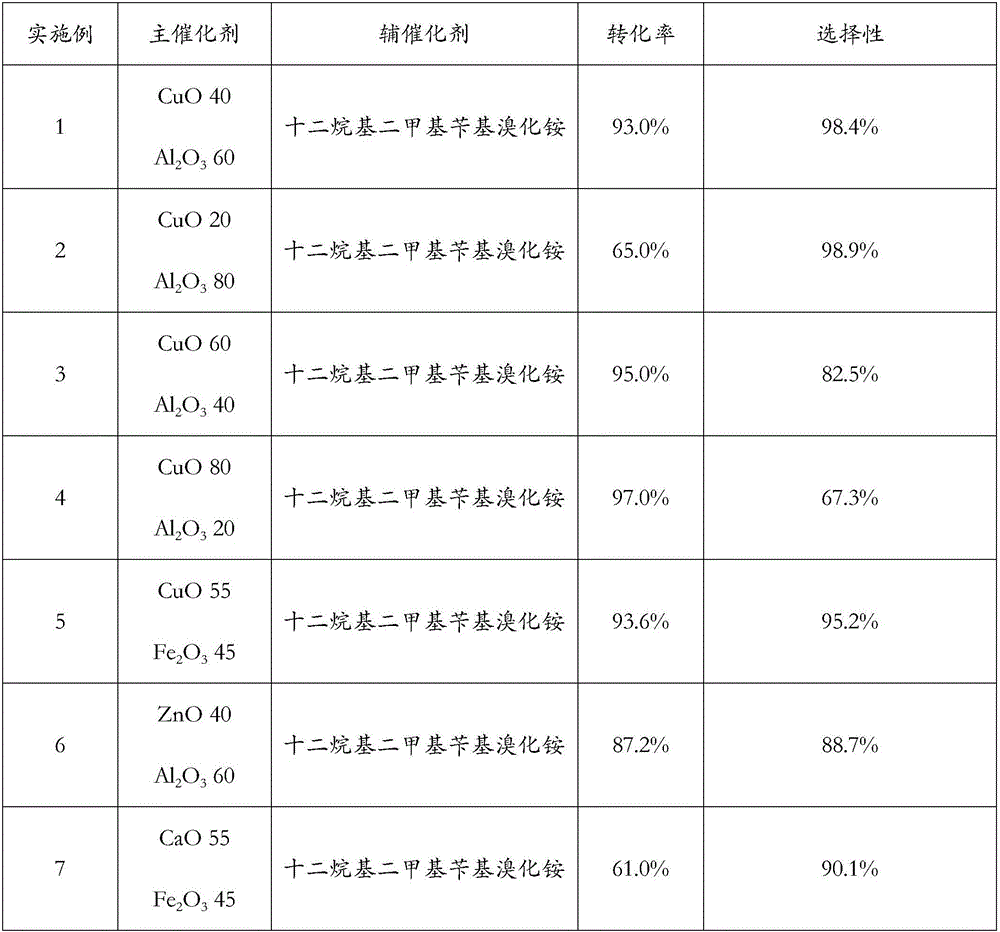

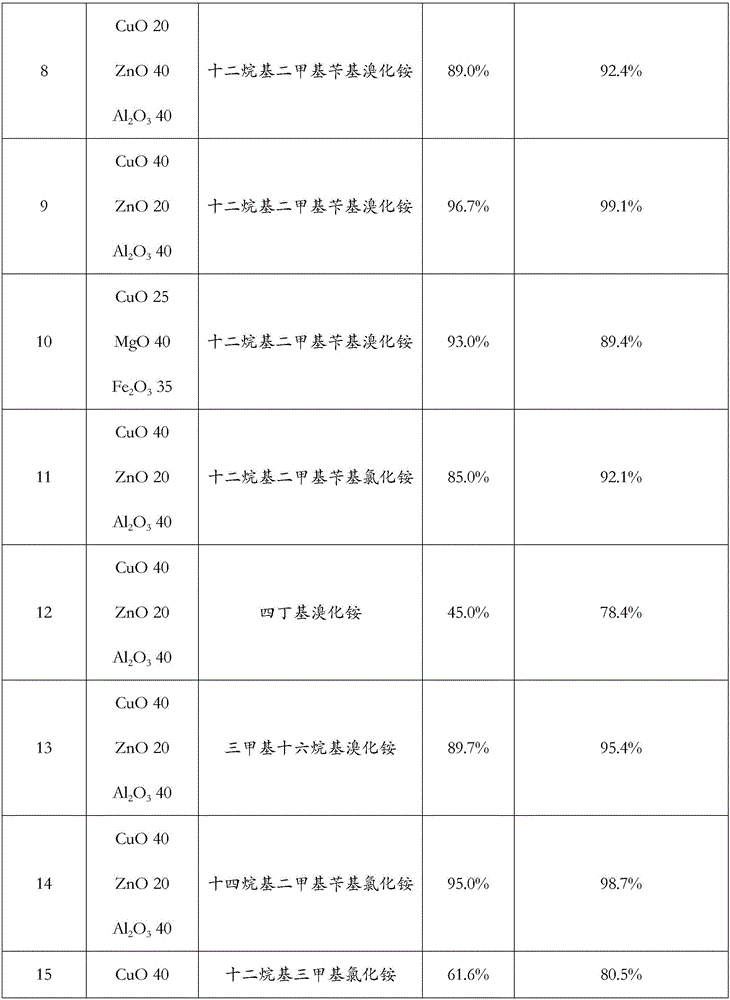

Examples

preparation example Construction

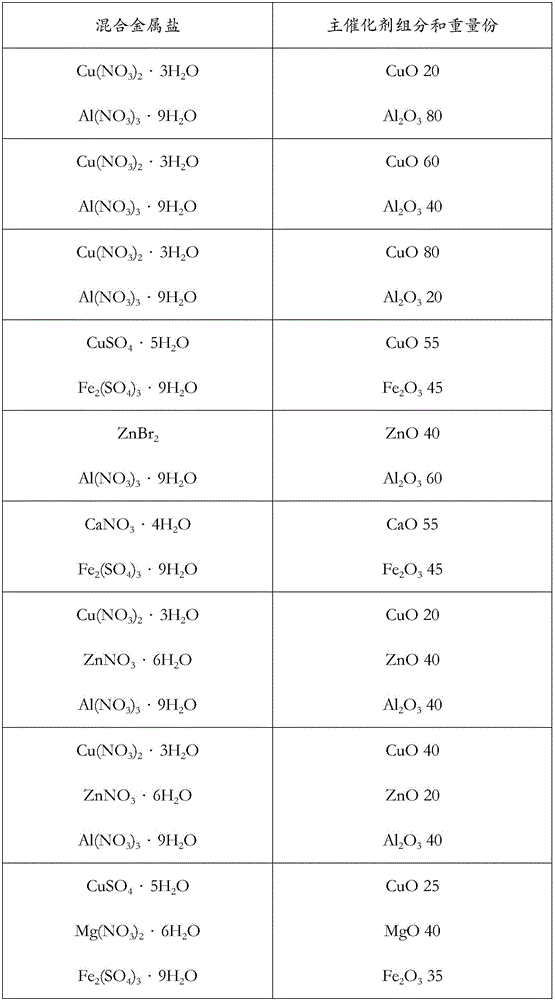

[0022] The invention discloses a preparation method of vinyl sulfate. Under the catalytic action of a catalyst, sulfur trioxide and ethylene oxide are used as reaction raw materials to react to generate vinyl sulfate in a solvent environment. Catalysts include main catalysts and auxiliary catalysts. The main catalyst is 0.1-5% of the mass of ethylene oxide. The reaction temperature of sulfur trioxide and ethylene oxide is 30-100° C.; the reaction pressure is 0.1-10.0 MPa. More preferably, the reaction temperature of sulfur trioxide and ethylene oxide is 50-80° C.; the reaction pressure is 3-5 MPa. The solvent may preferably be selected from one or a mixed solvent of dichloromethane, dichloroethane, carbon tetrachloride, chlorobenzene, cyclohexane, n-hexane, acetonitrile, and ethyl acetate. The dosage of the main catalyst is 1-3% of the mass of ethylene oxide. The weight ratio of the main catalyst to the auxiliary catalyst is 0.1-10.

[0023] The catalyst added in the chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com