Polyfunctional group polyphenylene ether resin and preparation method thereof

A polyphenylene ether resin and multifunctional technology, which is applied in the field of preparation of organic polymer compounds, can solve the problems of increasing the difficulty of the reaction process, the complexity of the equipment and the manufacturing cost, and achieve the effect of excellent performance, good performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

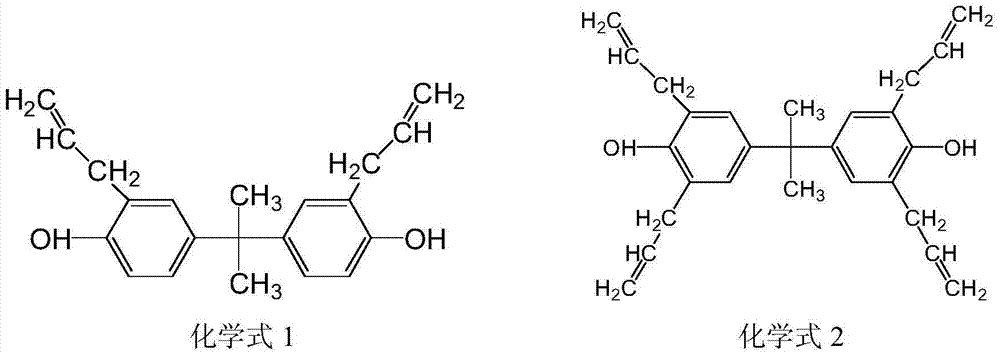

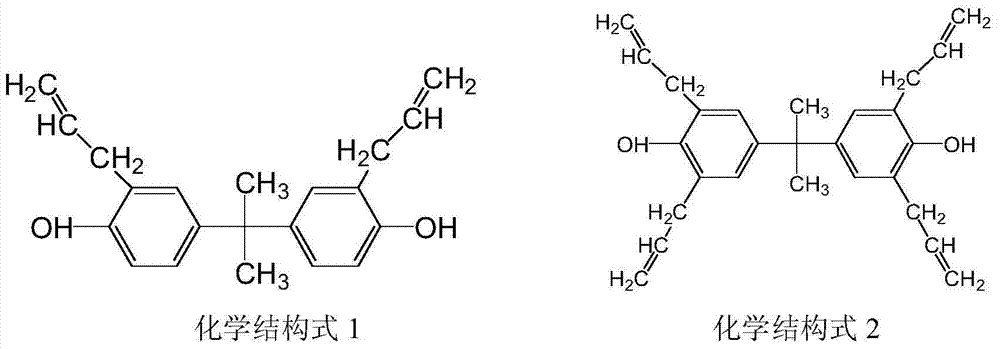

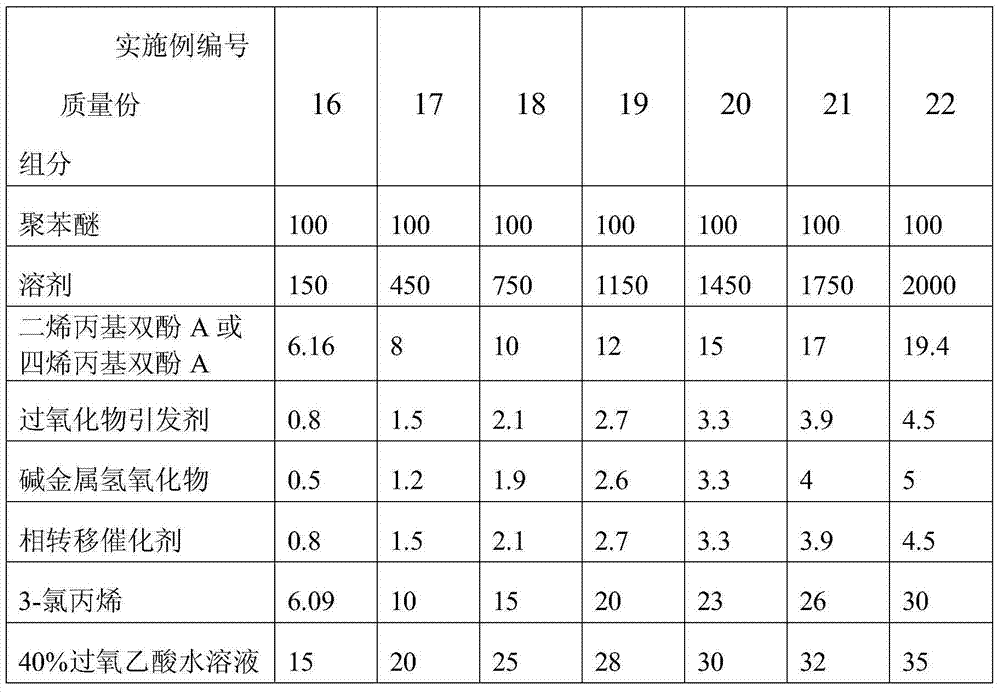

[0036]First, add 100 kg of polyphenylene ether (Asahi Kasei Chemical Co., Ltd., trade name S201A, number average molecular weight is 20000) in a non-airtight reactor A equipped with a reflux condenser, stirring, and a thermocouple, and add 210 kg of toluene As a solvent, heat up to 90°C and stir to dissolve the polyphenylene ether completely, then add 15.4kg of diallyl bisphenol A, at 90°C, add 4kg of benzoyl peroxide, add 6 times in half an hour , Stop the reaction after 3h. Second, add 2.2kg of sodium hydroxide and 1kg of tetrabutylammonium bromide to reactor A, add 30.4kg of 3-chloropropene dropwise at a temperature of 50°C, drop it for 1 hour, and continue the reaction at this temperature After 8 hours, the reaction solution of allylated polyphenylene ether resin was obtained. Thirdly, the allylated polyphenylene ether resin reaction solution obtained in reactor A was distilled, and the fraction at 50° C. was recovered. After there was no distillate, 18 kg of peroxyaceti...

Embodiment 2

[0039] First, add 100kg of polyphenylene ether (Blue Star New Materials, trade name LXR35, number average molecular weight 22000-28000) into a non-airtight reactor A equipped with a reflux condenser, stirring and thermocouple, and add 300 Use ㎏ toluene as a solvent, heat up to 84°C and stir to dissolve polyphenylene ether completely, then add 19㎏ tetraallyl bisphenol A, at 90°C, add 4 kg of benzoyl peroxide at one time, and react for 4 hours Stop responding. Second, add 2.2kg of sodium hydroxide and 2kg of tetrabutylammonium bromide to reactor A, add 19.4kg of 3-chloropropene dropwise at a temperature of 40°C, drop it in 0.75h, and continue at this temperature After reacting for 6 hours, an allylated polyphenylene ether resin reaction solution was obtained. Thirdly, distill the allylated polyphenylene ether resin reaction solution obtained in reactor A, and recover the fraction at 60°C. After there is no distillate, add 18 kg of peroxyacetic acid (40% content) and react at 4...

Embodiment 3

[0042] First, add 100 kg of polyphenylene ether (Asahi Kasei Chemical Co., Ltd., trade name S201A, number average molecular weight is 20000) in a non-airtight reactor A equipped with a reflux condenser, stirring, and a thermocouple, and add 210 kg of two Use toluene as solvent, heat up to 90°C and stir to dissolve polyphenylene ether completely, then add 15.4kg of diallyl bisphenol A, at 84°C, add 2.7kg of di-tert-butyl peroxide, three times in half an hour After the addition was completed, the reaction was stopped after 5 hours of reaction. Second, add 0.7kg of sodium hydroxide and 1.4kg of tetrabutylammonium chloride to reactor A, add 12.4kg of 3-chloropropene dropwise at a temperature of 30°C, drop it for 1 hour, and continue the reaction at this temperature After 8 hours, the reaction solution of allylated polyphenylene ether resin was obtained. Thirdly, the allylated polyphenylene ether resin reaction solution obtained in reactor A was distilled, and the fraction at 50° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distribution coefficient | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com