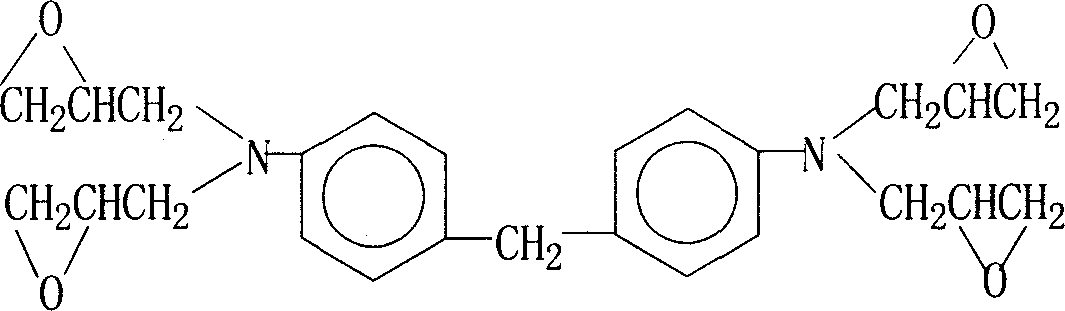

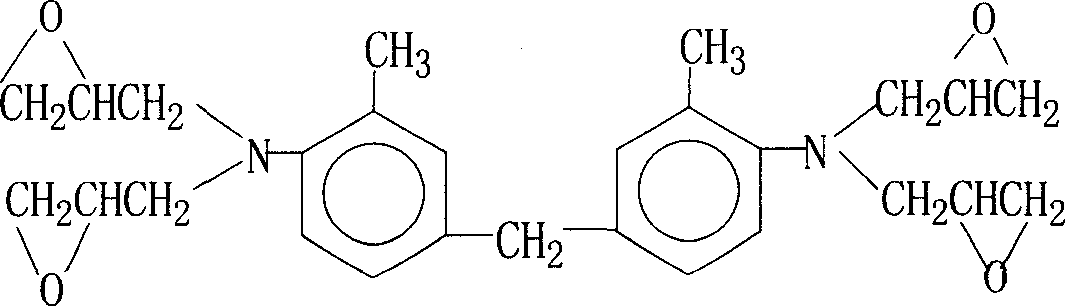

Process for preparing glycidic amine type polyfunctional epoxy resin

A technology of glycidyl amine type and epoxy resin, which is applied in chemical recycling, organic chemistry, etc., can solve the problems of unseen preparation methods, and achieve the effects of low cost, low production cost, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

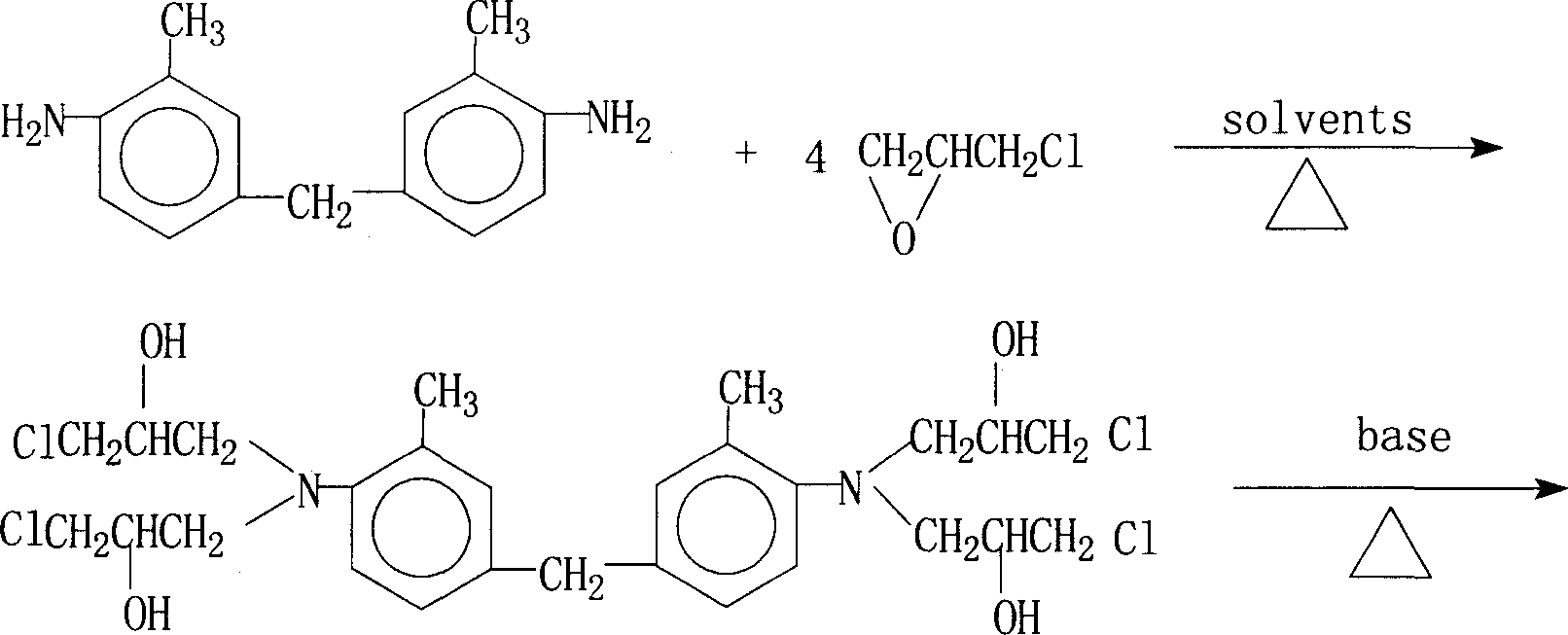

Method used

Image

Examples

Embodiment 1

[0026] 21.6 grams (0.1 moles) of 4,4'-methylene di-o-toluidine (MDT), 37 grams (0.4 moles) of epichlorohydrin (ECH), 10.8 grams of water and 22 milliliters of ethanol were added in a three-necked flask, and the After stirring and reacting for 7 hours at ℃, raise the reaction temperature, react at 80℃ for 2 hours, then raise the reaction temperature, and react at 90℃ for 1 hour, cool the reaction solution to 60℃, add dropwise 80 grams (0.4 moles) of 20% Concentrated sodium hydroxide aqueous solution, after dripping within 2 hours, continue to react at 80°C for 6 hours. Add 800 milliliters of toluene, stir to dissolve, filter to remove sodium chloride, wash the mother liquor with water, let stand, separate liquids, remove the water phase, and leave the organic phase mother liquor. The mother liquor is devolatilized in vacuum, and the volatile matter is collected for reuse in the next cycle; the residue after devolatilization is an amber viscous substance, which is N, N, N', N'-t...

Embodiment 2

[0028] 21.6 grams (0.1 moles) of 4,4'-methylene di-o-toluidine (MDT), 185 grams (2.0 moles) of epichlorohydrin (ECH), 2.16 grams of water and 38 milliliters of ethanol were added in a three-necked flask, at 40 After 4 hours of stirring reaction at ℃, raise the reaction temperature, react at 80℃ for 3 hours, then raise the reaction temperature, and react at 90℃ for 10 minutes, cool the reaction solution to 60℃, add dropwise 320 grams (1.6 moles) of 20% Concentrated sodium hydroxide aqueous solution, after dripping within 2 hours, continue to react at 80°C for 3 hours. Cool, stand still, separate liquid, remove sodium chloride solid and water, and obtain epichlorohydrin layer and resin layer. Recover epichlorohydrin for next recycling; put the resin layer into a three-necked flask, add 800 milliliters of toluene to the resin, stir to dissolve, wash the mother liquor with water, let stand, separate liquids, remove the water phase, and keep the organic phase mother liquor. The mo...

Embodiment 3

[0030] Except adding 92.5 grams (1.0 mole) of epichlorohydrin (ECH), 100 grams of 20% aqueous sodium hydroxide solution, other process steps, material quantities and reaction parameters are all the same as in Example 2. As a result, N, N, N', N'-tetraglycidyl-4,4'-methylenedi-o-toluidine (TGMDT) was obtained, which was measured by the amount of 4,4'-methylenedi-o-toluidine The yield is 98%, the epoxy value is 0.701, and the volatile matter is 0.94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com