Preparation method of polyphenyl ether adhesive and copper-clad plate thereof

A polyphenylene ether and adhesive technology, applied in polyether adhesives, adhesives, adhesive additives, etc., can solve problems such as high melting temperature, limited application, and poor melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Preparation of modified low molecular weight polyphenylene ether resin:

[0057] Modified low molecular weight polyphenylene ether resin Ⅰ

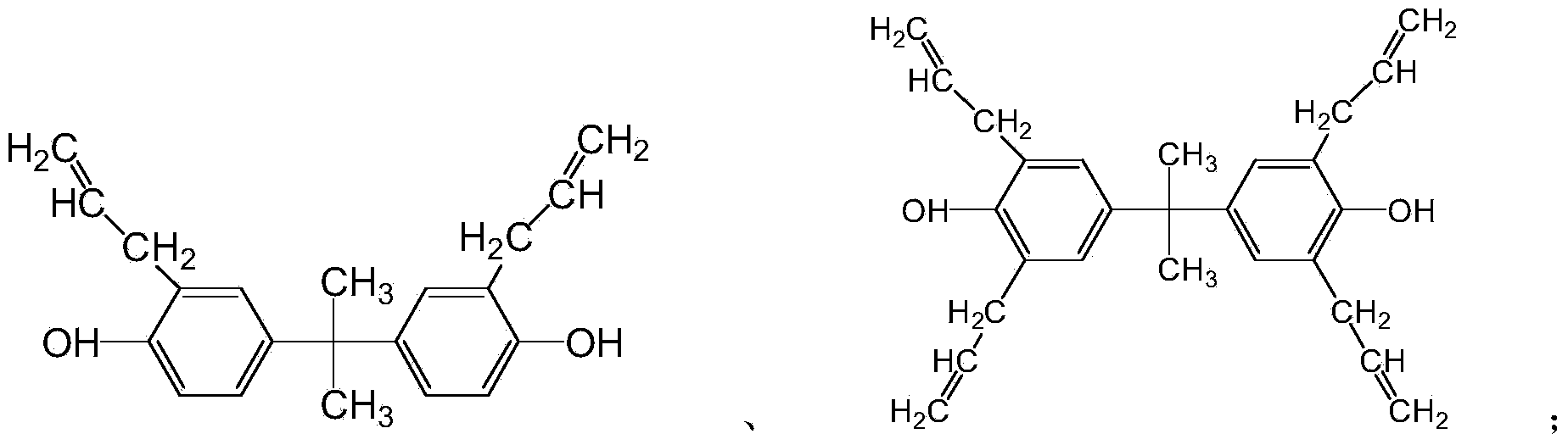

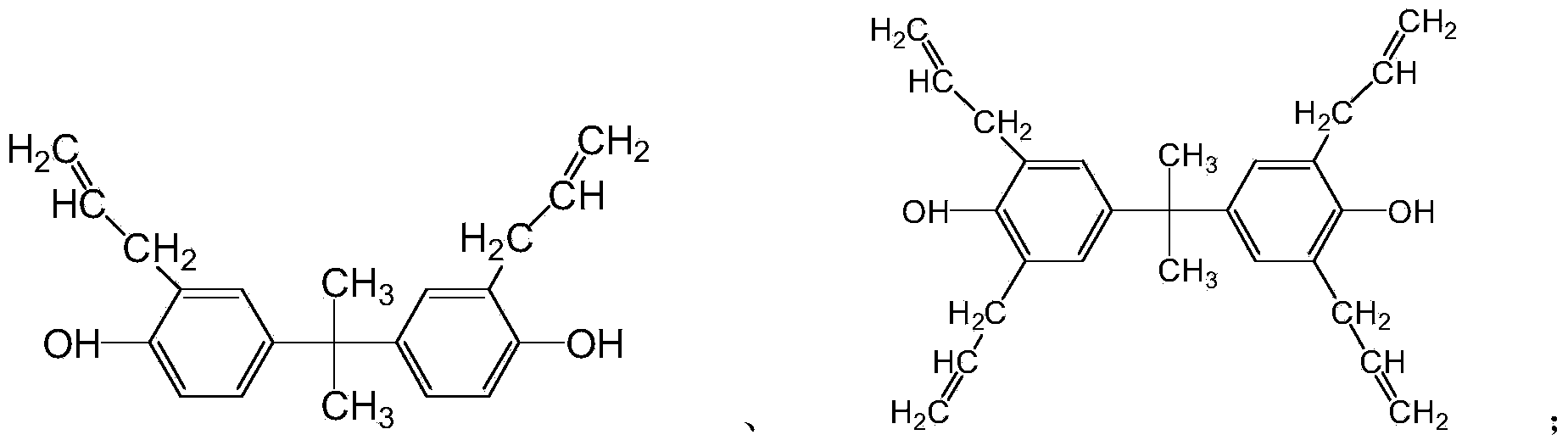

[0058] First, add 100 kg of polyphenylene ether (Asahi Kasei Chemical Co., Ltd., trade name S201A, number average molecular weight is 20,000) in a non-airtight reactor A equipped with a reflux condenser, stirring, and a thermocouple, and add 240 kg of toluene As a solvent, raise the temperature to 90°C and stir to dissolve the polyphenylene ether particles completely, then add 15.5kg of diallyl bisphenol A, at 55°C, add 3.2kg of benzoyl peroxide, add in 6 times within 0.5h Complete, stop reaction after reacting 3h. Second, add 2.2kg of sodium hydroxide and 1kg of tetrabutylammonium bromide to reactor A, add 30kg of 3-chloropropene dropwise at a temperature of 50°C, drop it for 1 hour, and continue the reaction at this temperature After 8 hours, the reaction solution of allylated polyphenylene ether resin was obtained. Thirdly, d...

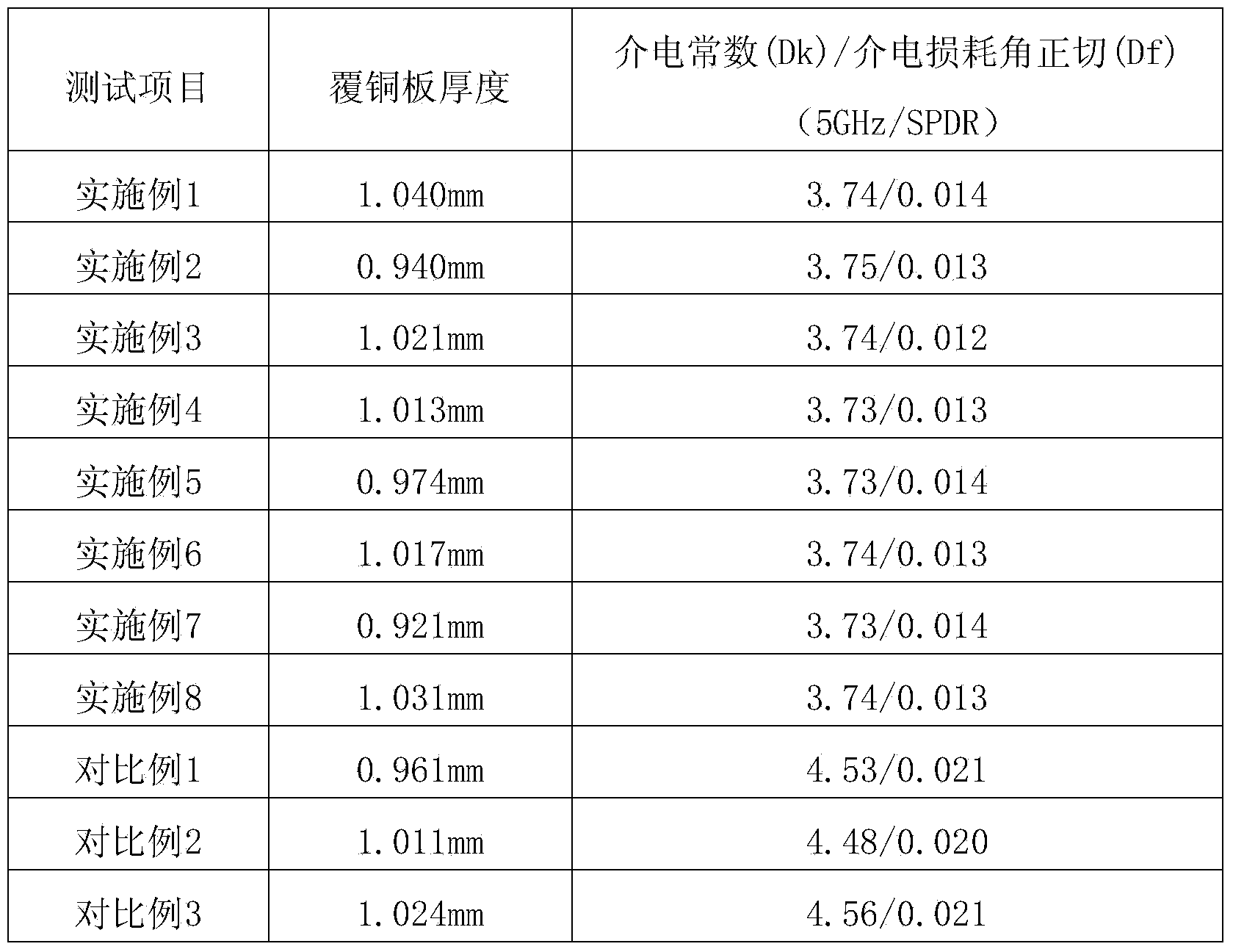

Embodiment 1

[0067] Take 100 kg of resin composition at room temperature (50 kg of the above-mentioned modified low molecular weight polyphenylene ether resin I, 29.4 kg of Dow 383 epoxy resin, 16 kg of bisphenol A benzoxazine resin, 4.6 kg of bismaleimide resin ㎏), 25 kg of magnesium hydroxide, 70 kg of toluene and 23 kg of methyl ethyl ketone were added to the plastic mixing tank, stirred for 1 hour, added 1.3 kg of imidazole, stirred at room temperature for 1 hour, and the molding time of the round hole method was 272 seconds under a hot plate at 171 °C. That is, the preparation of the polyphenylene ether adhesive is completed.

[0068] The glass fiber cloth 2116 is coated with polyphenylene ether adhesive through the gluing machine. The length of the drying channel of the gluing machine is 24m, divided into 3 sections, each section is 8m, and the baking temperature ranges from 70°C to 165°C. ℃, the speed (line speed) of the gluing machine is 2-10m / min, after the glass fiber cloth coate...

Embodiment 2

[0070]Take 100 kg of resin composition at room temperature (50 kg of the above-mentioned modified low molecular weight polyphenylene ether resin II, 26.8 kg of Dow 383 epoxy resin, 18 kg of bisphenol A benzoxazine resin, 5.2 kg of bismaleimide resin ㎏), talcum powder 26㎏, toluene 70㎏ and methyl ethyl ketone 23㎏ were added to the plastic mixing tank, stirred for 2 hours, added 1.3kg of triphenylphosphine, stirred at room temperature for 1 hour, and the molding time of the round hole method under a hot plate at 171°C was In 291 seconds, the preparation of the polyphenylene ether adhesive is completed.

[0071] The glass fiber cloth 2116 is coated with polyphenylene ether adhesive through the gluing machine. The length of the drying channel of the gluing machine is 24m, divided into 3 sections, each section is 8m, and the baking temperature ranges from 70°C to 165°C. ℃, the speed (line speed) of the gluing machine is 2-10m / min, after the glass fiber cloth coated with the polyphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com