Catalyst special for O-alkylation production of aromatic ether and method for producing aromatic ether

A technology of aromatic ethers and catalysts, applied in the field of catalysts and the production of aromatic ethers using the catalysts, can solve the problems of continuous industrial production of aromatic ethers and short catalyst life, and achieve the effects of high conversion rate, long catalyst life and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of a special catalyst for the production of aromatic ethers by O-alkylation.

[0022] Preparation of shaped support: 35g SiO 2 Mix evenly with 15g of pseudo-boehmite, then add 2% kale powder and mix, then add a nitric acid solution with a concentration of 8wt% after mixing evenly, after mixing evenly, extrude into strips; then dry at 120°C, and then Calcined at 540°C to obtain a catalyst-shaped carrier.

[0023] Impregnation of active components: prepare copper nitrate aqueous solution, the amount of copper nitrate is controlled in the catalyst active metal-copper content is 1.5% (wt.), then take 50g catalyst shaped carrier and join in the copper nitrate solution, at a constant temperature of 30 ℃ Immerse in a water bath for 12 hours; then dry at 120°C for 8 hours, and then roast at 550°C for 6 hours to obtain a semi-finished catalyst.

[0024] The impregnation of auxiliary agent component: the mixed solution of preparation ammonium phosphate an...

Embodiment 2~5

[0026] Examples 2-5: Preparation of special catalysts for producing aromatic ethers by O-alkylation.

[0027] The difference with Example 1 is that the carrier used is different, the carrier used in Example 2 is mercerized molecular sieve, the carrier used in Example 3 is aluminum phosphate, and the carrier used in Example 4 is SiO 2 and the mixture of mercerized molecular sieves, the carrier used in embodiment 5 is SiO 2 and aluminum phosphate mixture.

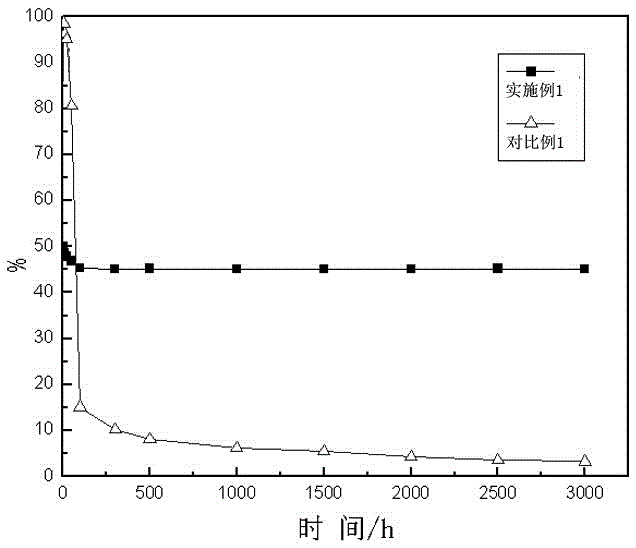

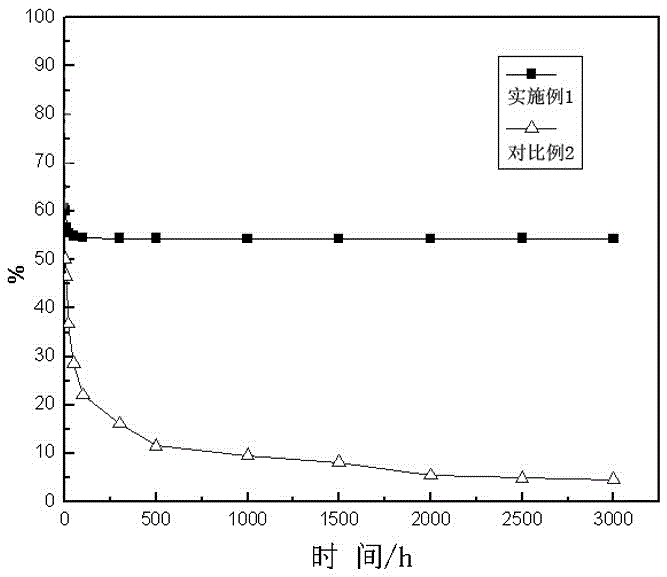

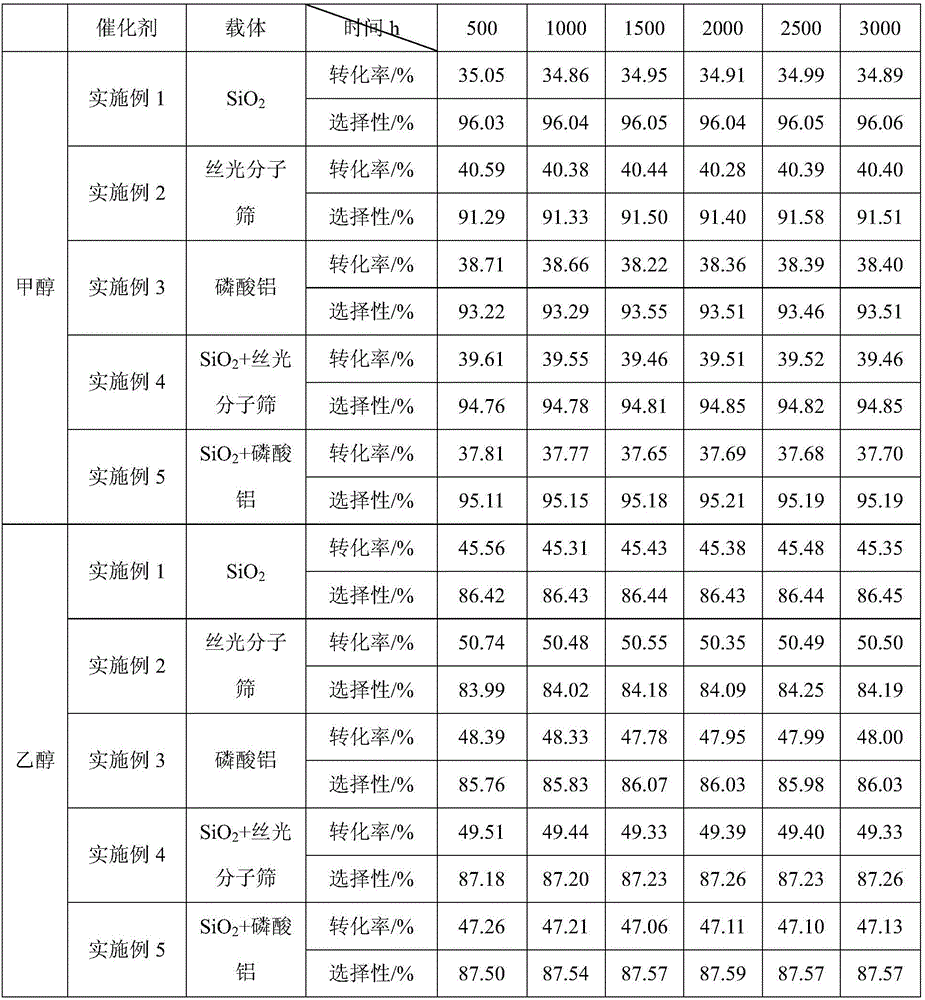

[0028] The catalysts prepared in Examples 1-5 were tested, and the results are shown in Table 1 and Table 2.

[0029] Table 1 is by catalyzing phenol and methyl alcohol, phenol and ethanol reaction to the evaluation result of embodiment 1~5 catalyst

[0030]

[0031] Table 2 by catalyzing catechol and methanol, catechol and ethanol reaction to the evaluation result of embodiment 1~5 catalyst

[0032]

[0033]

Embodiment 6~10

[0034] Examples 6-10: Preparation of special catalysts for producing aromatic ethers by O-alkylation.

[0035] The difference from Example 1 is that the loading of active components is different. The loading of active components in Example 6 is 0.1%, the loading of active components in Example 7 is 1.0%, and the loading of active components in Example 8 is 1.0%. The loading amount was 2.0%, the loading amount of the active ingredient in Example 9 was 3.0%, and the loading amount of the active ingredient in Example 10 was 5.0%.

[0036] The catalysts prepared in Examples 6-10 were tested and compared with Example 1, the results are shown in Table 3 and Table 4.

[0037] Table 3 is by catalyzing phenol and methanol, phenol and ethanol reaction to the evaluation result of embodiment 6~10 catalyst

[0038]

[0039]

[0040] Table 4 by catalyzing the reaction of catechol and methanol, catechol and ethanol to the evaluation result of the catalyst prepared in Examples 6-10

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com