Method for preparing 1,6-hexanediol by catalytic hydrogenolysis of 1,2,6-hexanetriol

A technology for catalyzing hydrogen and catalytic hydrogenolysis of hexanetriol, applied in chemical instruments and methods, reduction preparation of oxygen-containing functional groups, physical/chemical process catalysts, etc. Low-level problems, to achieve the effect of short reaction time, high yield and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Catalyst preparation and catalytic hydrogenolysis experiment

[0019] The catalyst is prepared by impregnation method, the carrier is nano-zirconia, impregnated with equal volume of metal salt aqueous solution, dried at 110°C for 12h after impregnation, then roasted in air atmosphere at 350°C for 3h, and finally reduced in hydrogen atmosphere at 300°C for 2h. When activated carbon is used as the carrier, the air atmosphere is changed to high-purity nitrogen, and other conditions are the same as before. Then take a certain amount of 1,2,6-hexanetriol, reaction solvent, catalyst and solid acid in a 25mL stainless steel reaction kettle, and inject hydrogen gas at a certain pressure to repeatedly replace the air in the kettle. Raise the temperature to the specified temperature and react for a certain period of time. After the reaction, the reactor was cooled to room temperature, and finally filtered with suction and chromatographic analysis was performed on the reaction so...

Embodiment 2

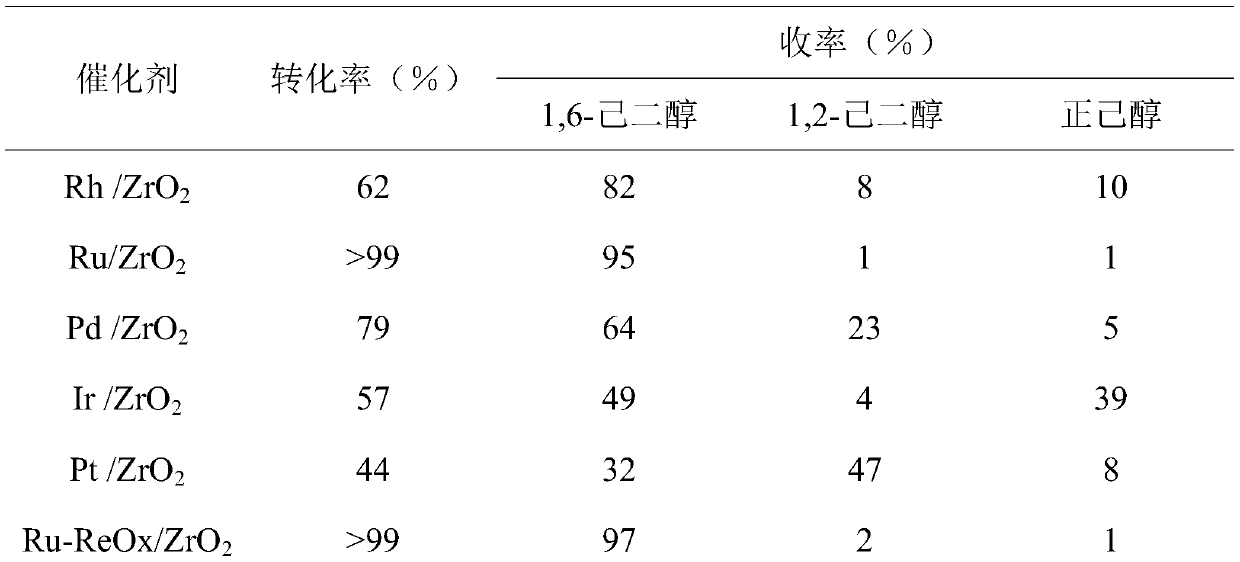

[0021] Table 1 The results of catalytic hydrogenolysis of 1,2,6-hexanetriol to 1,6-hexanediol over different active metal catalysts (160°C, 1MPa H 2 , the solvent is 2mL water, the amount of 1,2,6-hexanetriol is 5mmol, the loading amount of the active component is 5wt%, the co-catalyst: the active ingredient=1, the amount of the catalyst is 5wt%, and the amount of phosphotungstic acid is 5wt% %, the reaction time is 2h)

[0022]

[0023]

[0024] It can be seen from Table 1 that the best active component is Ru and the best promoter is Re. Take Ru-ReOx / ZrO 2 When used as a catalyst, the substrate is completely converted, and the yield of 1,6-hexanediol is 97%. Followed by Ru / ZrO 2 When used as a catalyst, the substrate is completely converted, and the yield of 1,6-hexanediol is 95%. Considering economic issues, the catalyst used in the following experiments is Ru / ZrO 2 .

Embodiment 3

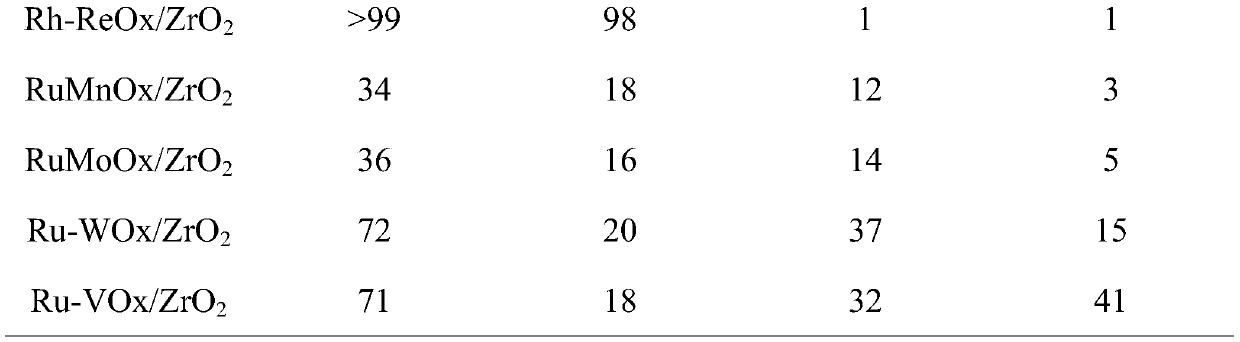

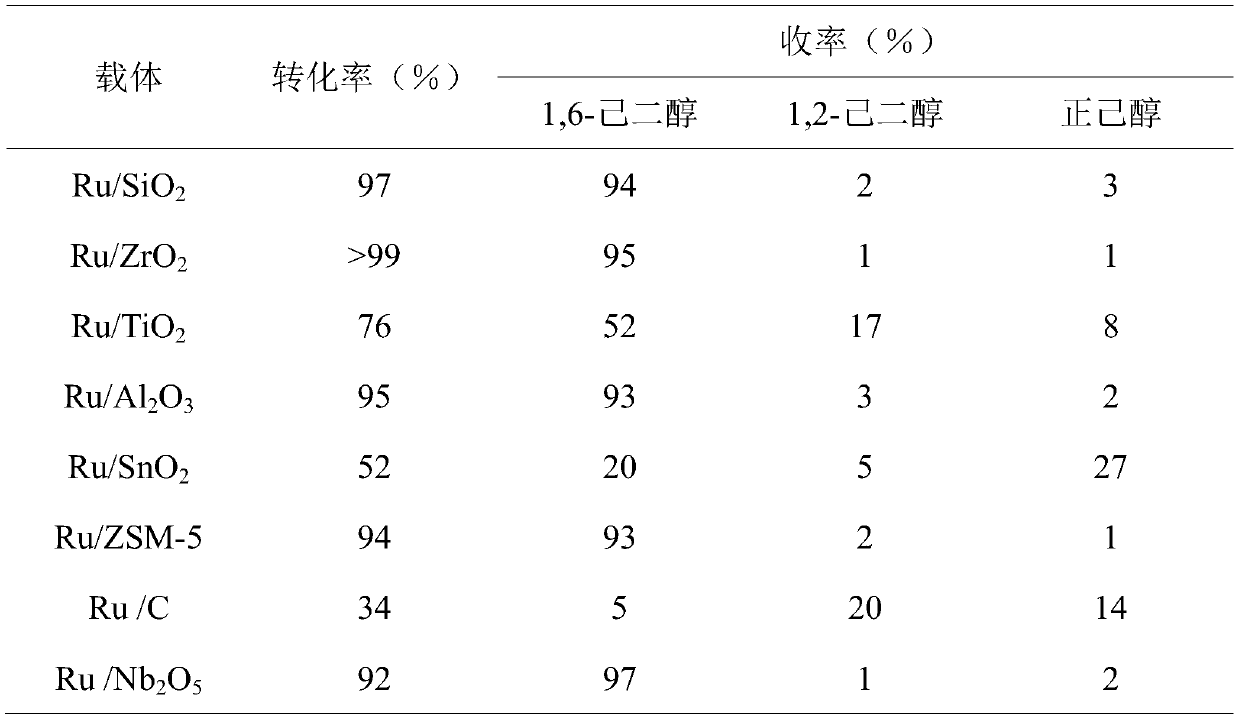

[0026] Table 2 The results of catalytic hydrogenolysis of 1,2,6-hexanetriol to 1,6-hexanediol on different catalyst supports (160°C, 1MPaH 2 , the solvent is 2mL water, the amount of 1,2,6-hexanetriol is 5mmol, the Ru load is 5wt%, the catalyst amount is 5wt%, the phosphotungstic acid amount is 5wt%, and the reaction time is 2h)

[0027]

[0028] It can be seen from Table 2 that the best carrier for the active component under the same reaction conditions is ZrO 2 , At this time, 1,2,6-hexanetriol was completely converted, and the yield of 1,6-hexanediol was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com