Method for synthetizing liposoluble tea polyphenols by enzymic method

A fat-soluble tea polyphenol, enzymatic synthesis technology, applied in the direction of fermentation, can solve the problems of many reaction steps, difficult separation and purification, poor regioselectivity, etc., and achieves the effects of mild reaction conditions, simple product separation, and fewer reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 100mg of 88% tea polyphenols and vinyl acetate were placed in a 100mL stoppered reaction flask in a mass ratio of 4: 1, and then 50mL of isopropanol was added and mixed evenly. When the temperature of the reaction system rises to 40°C, add 1.5 mg of lipase LIPOZYME TL IM produced by Novo Nordisk Company to start the reaction, and stir the reaction at 40°C for 16 hours. Tea polyphenol product 75.8mg.

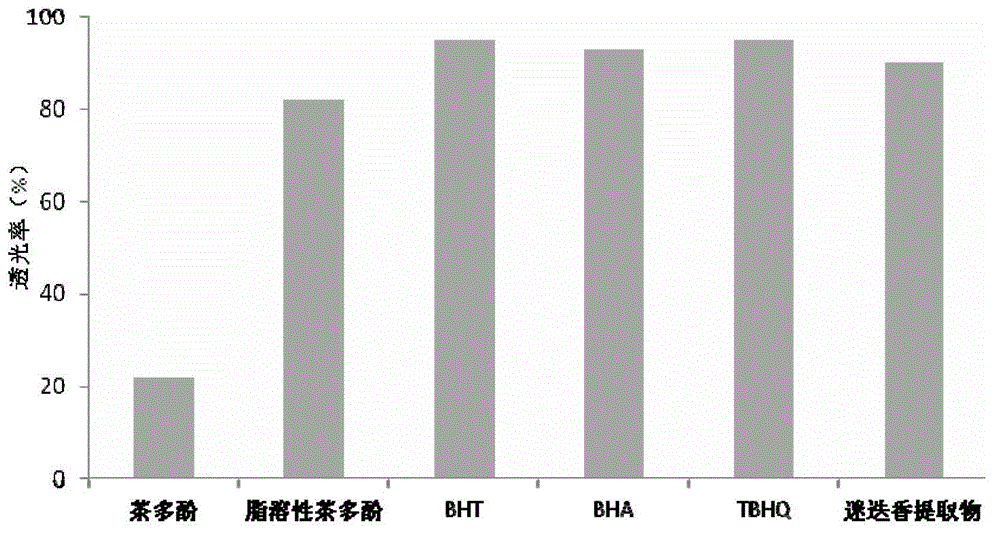

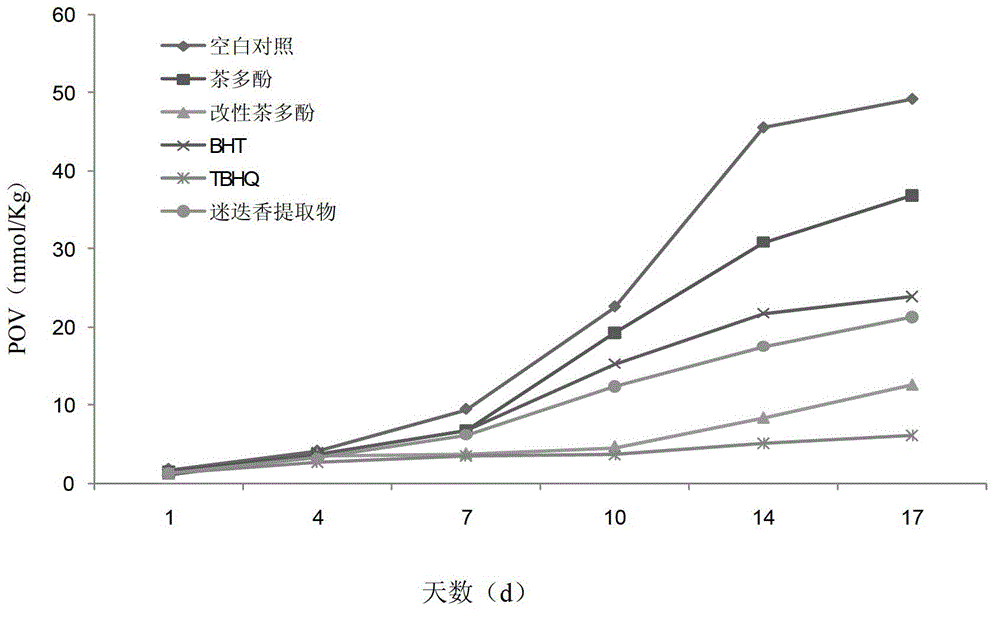

[0018] The fat-soluble tea polyphenol product prepared in this embodiment is measured by light transmittance (see figure 1 ) showed good solubility in oil, which was significantly higher than that of unmodified tea polyphenols. Peroxide value test results of oils and fats (see figure 2 ) showed that in edible soybean oil, when the addition amount was 0.02%, the antioxidant effects of different antioxidants were as follows: TBHQ > oil-soluble tea polyphenols > rosemary extract > BHT > unmodified tea polyphenols.

Embodiment 2

[0020] Put 50mg of 98% tea polyphenols and vinyl butyrate in a mass ratio of 5:1 in a 50mL stoppered reaction bottle, then add 25mL of acetonitrile and mix evenly, and the above reaction system is moved into a heat-collecting magnetic heating stirrer, and wait for the reaction When the temperature of the system rises to 50°C, add 1.0 mg of lipase LPOZYME RM IM produced by Novo Nordisk to start the reaction, stir and react at 50°C for 12 hours, after the reaction is completed, the reaction solution is filtered, rotary evaporated, and vacuum-dried to obtain fat-soluble tea Polyphenol product 32.4 mg.

Embodiment 3

[0022] Put 80mg of 95% tea polyphenols and vinyl neodecanoate in a mass ratio of 4:1 in a 100mL stoppered reaction bottle, then add 50mL of tert-butanol and mix evenly, and the above reaction system is moved into a heat collecting type magnetic heating stirrer , when the temperature of the reaction system rises to 50°C, add 1.0mg of lipase Lipase AYS "Amano" produced by Amano Pharmaceutial Company to start the reaction, stir and react at 50°C for 20h, after the reaction, the reaction solution is filtered, rotary evaporated, vacuum Dry to obtain fat-soluble tea polyphenol product 58.2mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com