Preparation method and application of nanometer vanadium pentoxide anode material suitable for industrial production

A technology of vanadium pentoxide and positive electrode materials, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of limiting the application of vanadium pentoxide, low production efficiency, unfavorable industrialization, etc., and achieve easy scale-up production, low cost, and feasibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

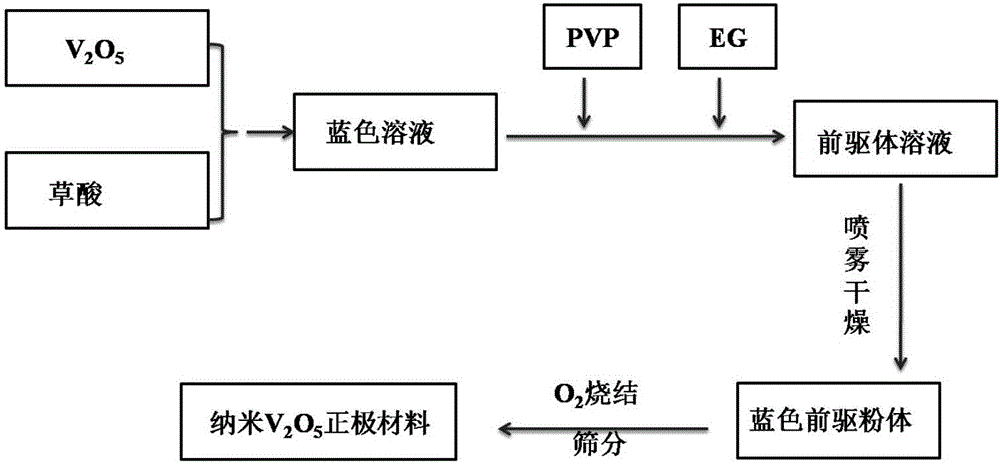

[0028] Example 1, see Figure 1 to Figure 5 :

[0029] The present invention provides a kind of preparation method of nano-vanadium pentoxide cathode material suitable for industrialized production, comprising the following steps (see attached figure 1 ):

[0030] 1) Put 16.368Kg V 2 o 5 , 68.1Kg dihydrate oxalic acid was added to deionized water to form a blue solution;

[0031] 2) Add 15Kg of PVA and 5L of EG (with a density of 1.1155g / mL) into the blue solution respectively to obtain a blue precursor solution;

[0032] 3) Pump the blue precursor solution into a centrifugal spray dryer for spray drying to obtain a blue precursor powder;

[0033] 4) Sinter the blue precursor powder at 500°C for 3 hours under aerobic conditions, and sieve to obtain the product.

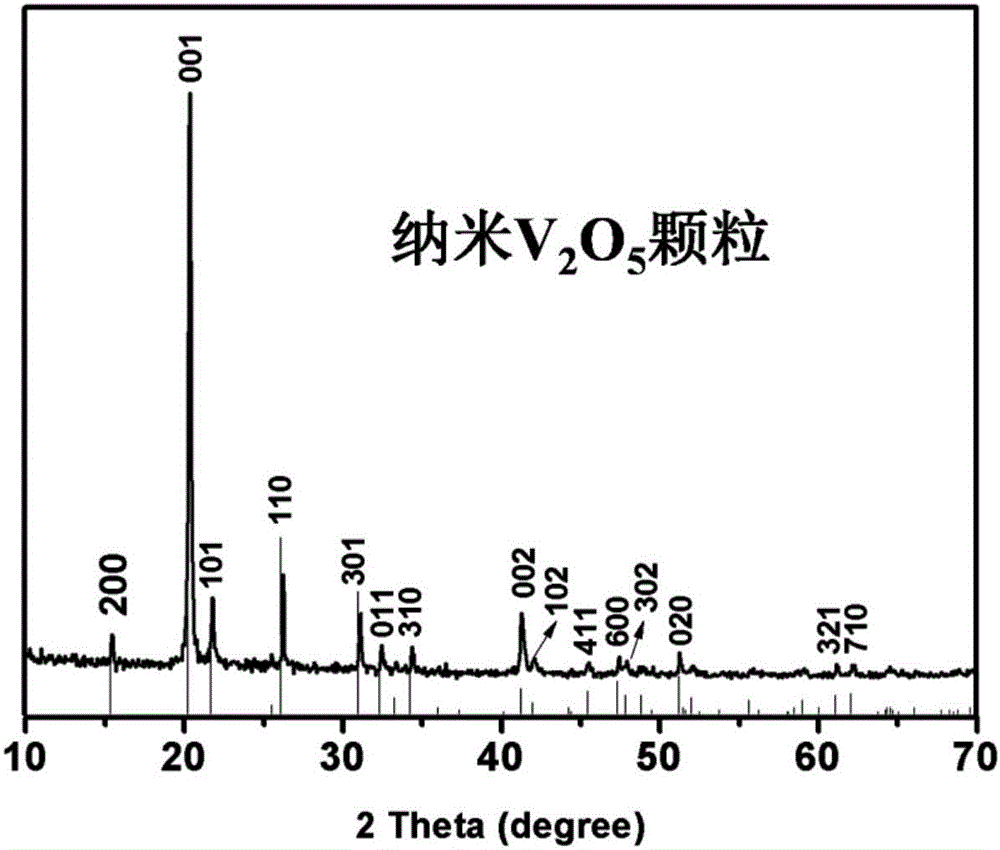

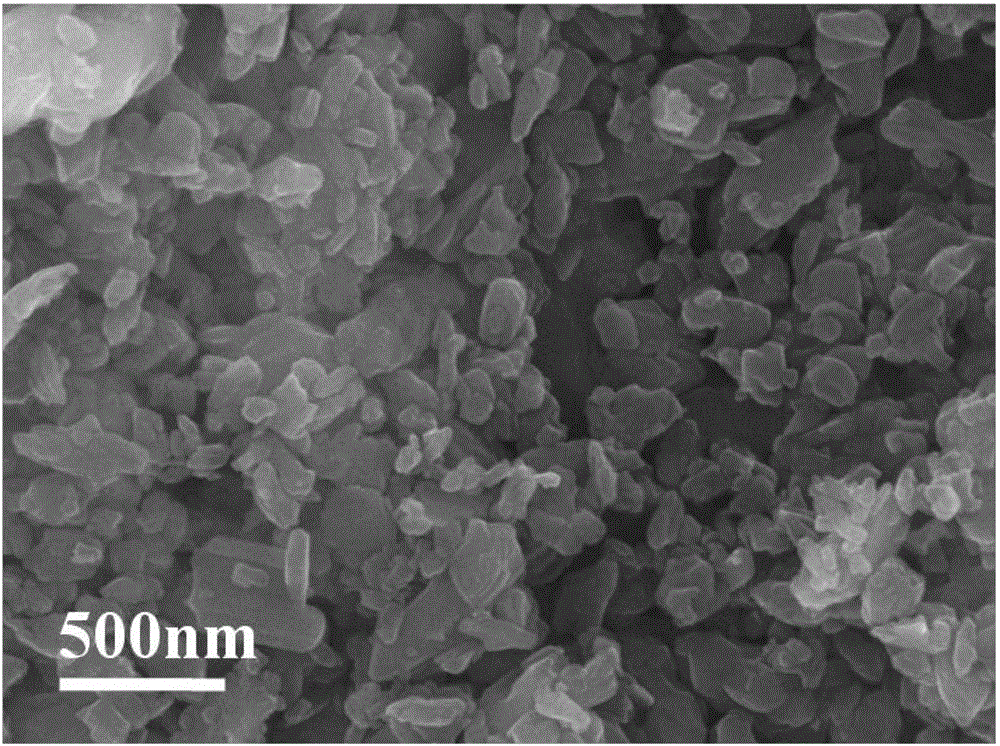

[0034] The structure of the present embodiment product is measured by X-ray diffractometer, and the results are shown in the attached figure 2 , X-ray diffraction pattern (XRD) shows that the nanopowder struct...

Embodiment 2

[0040] The invention provides a method for preparing a nano vanadium pentoxide cathode material suitable for industrial production, comprising the following steps:

[0041] 1) 21.055Kg NH 4 VO 3 , 68.1Kg dihydrate oxalic acid was added to deionized water to form a blue solution;

[0042] 2) Add 12Kg PEG-4000 and 2L EG (with a density of 1.1155g / mL) to the blue solution respectively to obtain a blue precursor solution;

[0043] 3) Pump the blue precursor solution into a centrifugal spray dryer for spray drying to obtain a blue precursor powder;

[0044]4) Sinter the blue precursor powder at 350°C for 8 hours under aerobic conditions, and sieve to obtain the product.

[0045] The product nanometer V of present embodiment gained 2 o 5 As a positive electrode active material for lithium ions, its specific capacity can reach 126.7mAh / g at 2.5-4V (1C=150mAh / g) and 0.5C. After 200 cycles, its specific capacity still reaches 116.7mAh / g. The rate is 92.1%.

Embodiment 3

[0047] The invention provides a method for preparing a nano vanadium pentoxide cathode material suitable for industrial production, comprising the following steps:

[0048] 1) Put 16.368Kg V 2 o 5 136.2Kg oxalic acid dihydrate was added to deionized water to form a blue solution;

[0049] 2) Add 15Kg of glucose and 2L of EG (with a density of 1.1155g / mL) into the blue solution respectively to obtain a blue precursor solution;

[0050] 3) Pump the blue precursor solution into a centrifugal spray dryer for spray drying to obtain a blue precursor powder;

[0051] 4) Sinter the blue precursor powder at 550°C for 8 hours under aerobic conditions, and sieve to obtain the product.

[0052] The product nanometer V of present embodiment gained 2 o 5 As a positive electrode active material for lithium ions, its specific capacity can reach 125.7mAh / g at 2.5-4V (1C=150mAh / g) and 0.5C, and its specific capacity can still reach 114.2mAh / g after 200 cycles. The rate is 90.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com