A metal-organic framework and ionic liquid composite material and its preparation method and application

A metal organic framework, ionic liquid technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of equipment corrosion, volatile adsorbents, etc., to achieve non-toxic materials, high adsorption value, easy to achieve Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A metal-organic framework and ionic liquid composite material for carbon dioxide adsorption, the preparation method comprising the following steps:

[0031] Preparation of ionic liquid: in a 50mL two-necked flask, under N 2 Dissolve 3 mL of 1,2-dibromoethane and 4 mL of N-(3-aminopropyl) imidazole in 10 mL of acetone under protection, stir at room temperature to obtain a dark brown viscous liquid, separate by centrifugation, and then wash with acetone to obtain an ionic liquid ( 1-(3-aminopropyl)-3-(2-bromoethyl)imidazole bromide);

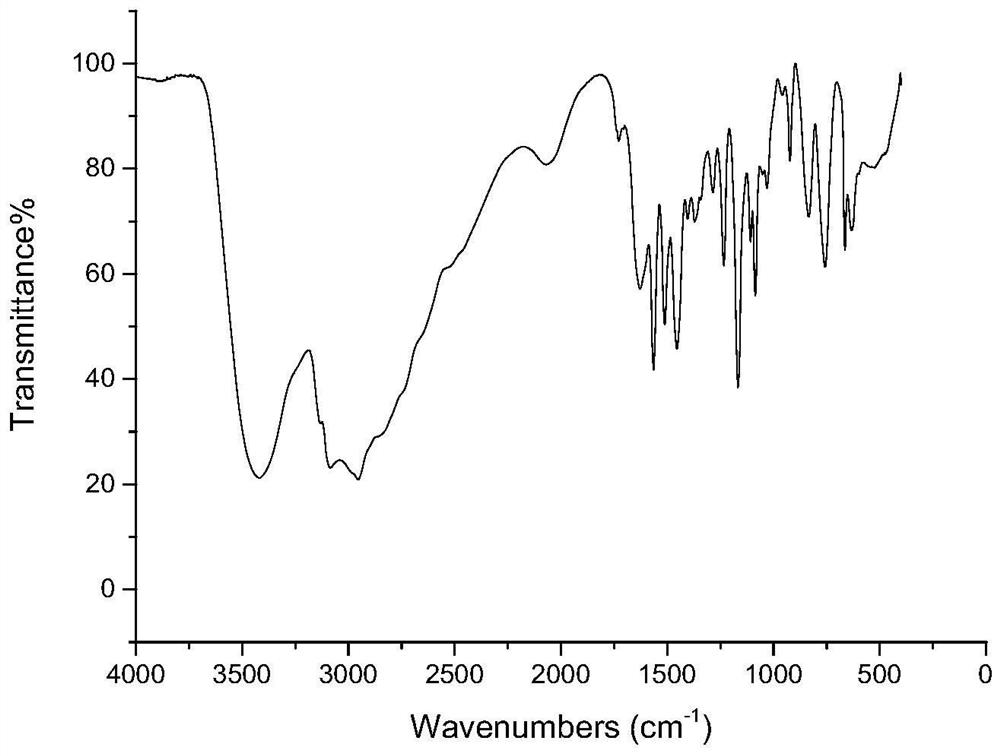

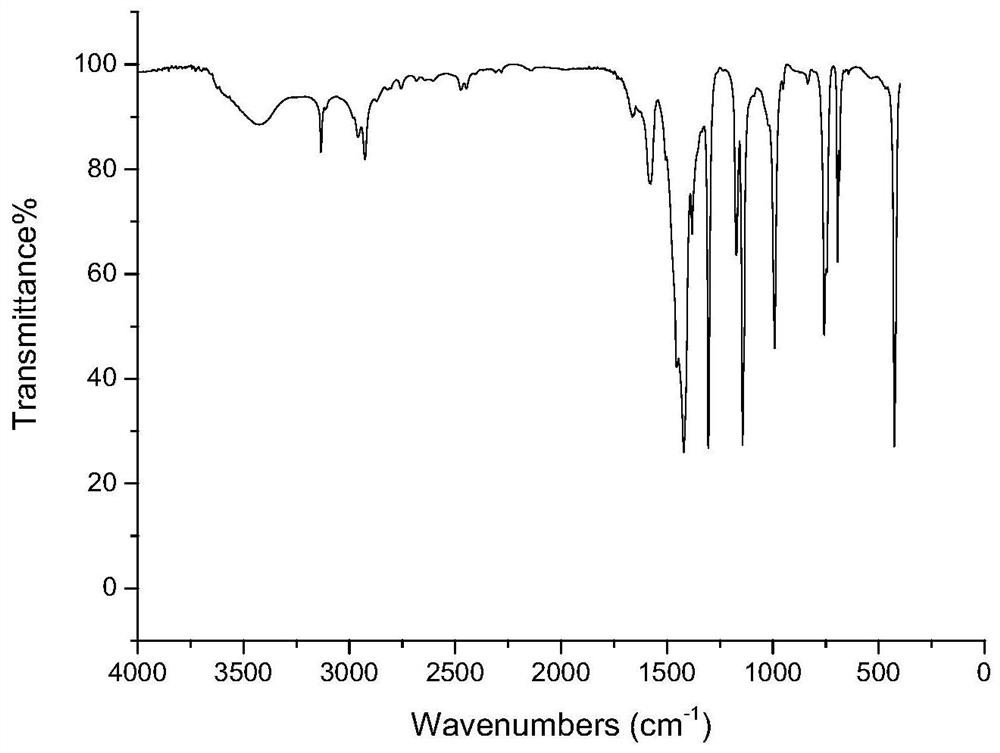

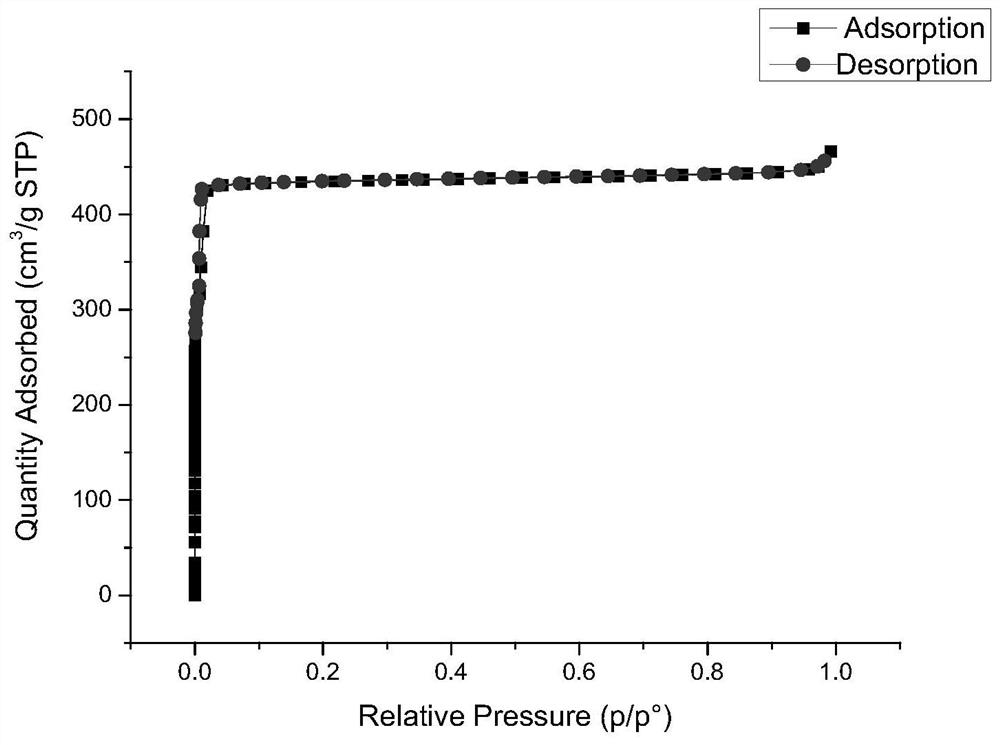

[0032] Dissolve 120 mg of the above-prepared ionic liquid in 30 mL of methanol, then add 1.232 g of 2-methylimidazole, stir at room temperature for 12 h to obtain an ionic liquid solution, dissolve 1.096 g of cobalt nitrate hexahydrate in 30 mL of methanol to obtain a cobalt nitrate solution, Then the ionic liquid solution was poured into the cobalt nitrate solution, stirred for 10 min, and allowed to stand for 24 h to obtain a purple prec...

Embodiment 2

[0039] A metal-organic framework and ionic liquid composite material for carbon dioxide adsorption, the preparation method comprising the following steps:

[0040] Preparation of ionic liquid: in a 50mL two-necked flask, under N 2Dissolve 3 mL of 1,2-dibromoethane and 4 mL of N-(3-aminopropyl) imidazole in 10 mL of acetone under protection, stir at room temperature to obtain a dark brown viscous liquid, separate by centrifugation, and then wash with acetone to obtain an ionic liquid;

[0041] Dissolve 90 mg of the ionic liquid prepared above in 30 mL of methanol, then add 1.232 g of 2-methylimidazole, stir at room temperature for 12 h to obtain an ionic liquid solution, dissolve 1.096 g of cobalt nitrate hexahydrate in 30 mL of methanol to obtain a cobalt nitrate solution, Then the ionic liquid solution was poured into the cobalt nitrate solution, stirred for 10 min, and allowed to stand for 24 h to obtain a purple precipitate, which was centrifuged, washed repeatedly with met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com