Preparation method of cotton stalk based activated carbon

A technology based on activated carbon and activated carbon, applied in the field of activated carbon, can solve problems such as waste of biomass resources, indigestion by livestock and poultry, damage to soil structure, etc., and achieve the effects of increasing the adsorption value of copper ions, increasing the interest rate of activated carbon, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

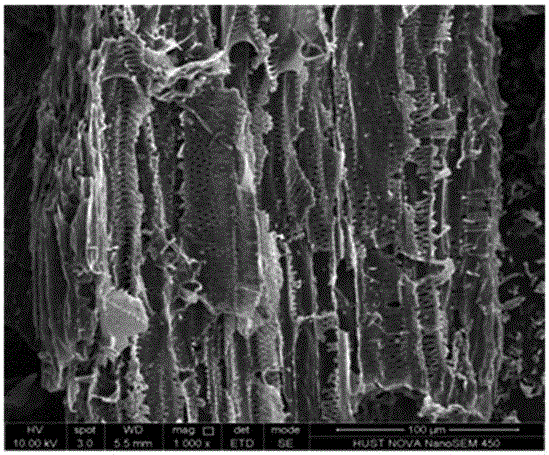

[0031] 50 g of cotton stalks were washed, dried, and crushed to 40 mesh. Mix cotton stalk powder with 10wt% sodium hydroxide solution at a mass ratio of 2:1, let it stand for 12 hours, filter it, and dry it at 105°C for 12 hours, then put the cotton stalk powder into a porcelain crucible, and heat it in an intelligent muffle furnace. According to the heating rate of 20 ℃ / min to 250 ℃, carbonization 150min, cooling with the furnace, washing to neutral, drying, the obtained cotton stalk-based activated carbon, the yield rate is 67.77%, the adsorption value of copper is 7.41mg / g.

[0032] Comparative test: Wash 50g of cotton stalks, dry them, and crush them to 40 meshes. In the intelligent muffle furnace, the temperature was raised to 250 °C at a rate of 20 °C / min, carbonized for 150 min, and cooled with the furnace. Put it in place for 12 hours, filter, wash with water until neutral, dry, heat up to 250°C in a muffle furnace at a heating rate of 20°C / min, activate for 150min,...

Embodiment 2

[0034] 50 g of cotton stalks were washed, dried, and crushed to 40 mesh. Mix cotton stalk powder with 15wt% sodium hydroxide solution at a mass ratio of 0.5:1, let it stand for 12 hours, filter it, and dry it at 105°C for 12 hours, then put the cotton stalk powder into a porcelain crucible, and heat it in an intelligent muffle furnace. According to the heating rate of 20 ℃ / min to 350 ℃, carbonization 150min, cooling with the furnace, washing to neutral, drying, the obtained cotton stalk-based activated carbon, the yield is 47.41%, the adsorption value of copper is 7.02mg / g.

[0035] Comparative test: Wash 50g of cotton stalks, dry them, and crush them to 40 meshes. In the intelligent muffle furnace, the temperature was raised to 350°C at a rate of 20°C / min, carbonized for 150min, and cooled with the furnace. The obtained cotton stalk charcoal was mixed with a sodium hydroxide solution with a concentration of 15wt% at a mass ratio of 0.5:1, and statically Filter after 12 hou...

Embodiment 3

[0037] 50 g of cotton stalks were washed, dried, and crushed to 40 mesh. Mix cotton stalk powder with 20wt% sodium hydroxide solution at a mass ratio of 1:1, filter after standing for 12 hours, and dry at 105°C for 12 hours, then put the cotton stalk powder into a porcelain crucible, and heat it in an intelligent muffle furnace. According to the heating rate of 20 ℃ / min to 300 ℃, carbonization 60min, cooling with the furnace, washing to neutral, drying, the existing cotton stalk-based activated carbon, the yield rate is 34.23%, the adsorption value of copper is 7.39mg / g.

[0038] Comparative test: Wash 50g of cotton stalks, dry them, and crush them to 40 meshes. In the intelligent muffle furnace, the temperature was raised to 300°C at a rate of 20°C / min, carbonized for 60min, and cooled with the furnace. Filter after 12 hours, dry at 105°C for 12 hours, wash with water until neutral, dry, then put the cotton stalk charcoal into a porcelain crucible, raise the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com