Soy sauce filtering method

A filtration method and soy sauce technology, applied in application, food preparation, food science and other directions, can solve the problems of affecting product sensory and quality, reducing the yield of soy sauce finished products, and large loss of pigment components, so as to ensure high-end market share and reduce soy sauce. The effect of precipitation and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

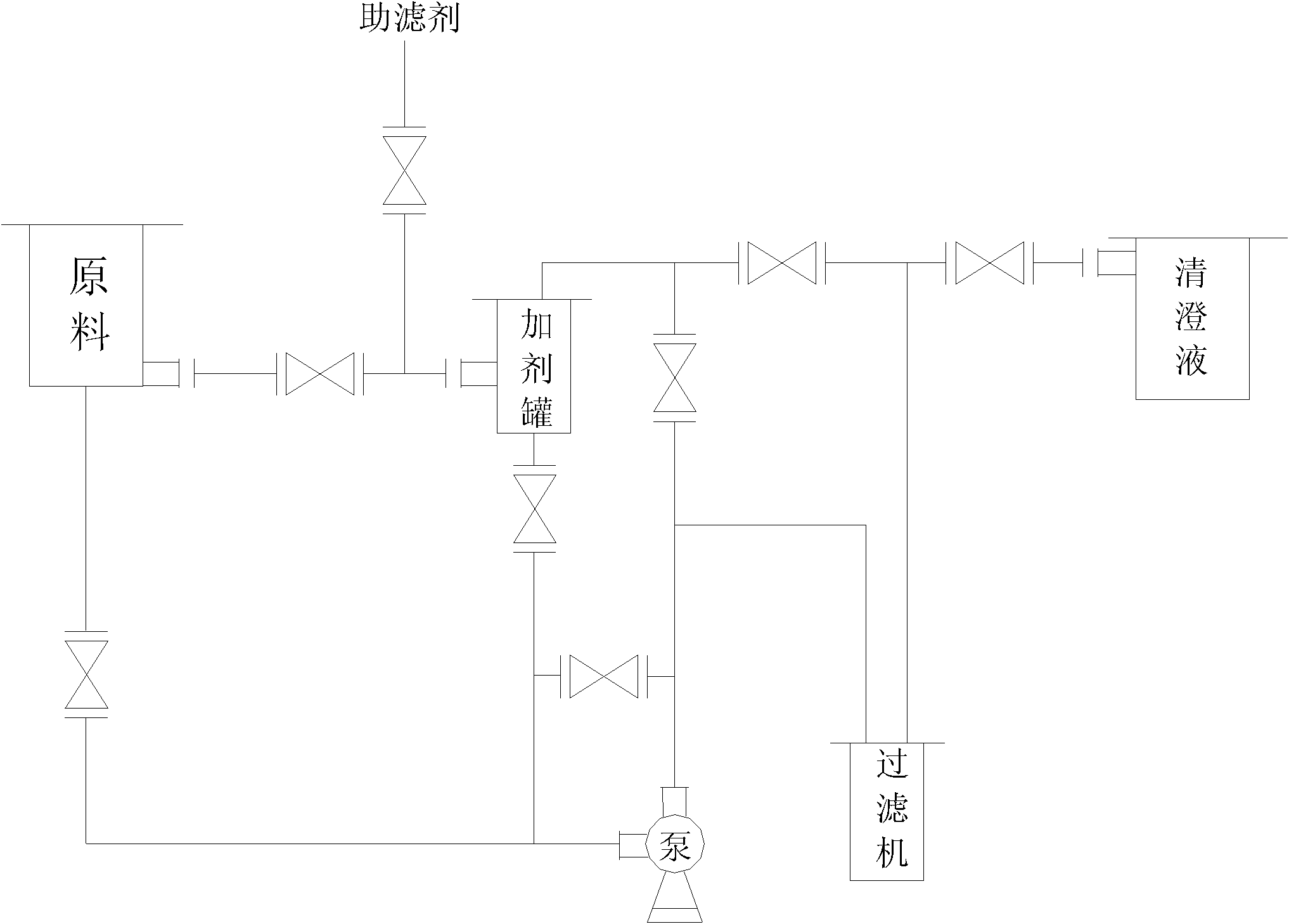

Method used

Image

Examples

Embodiment 1

[0018] 1) Raw material preparation: add 400kg of soy sauce into the additive tank for use;

[0019] 2) Add filter aid: add 15kg filter aid perlite, and start stirring;

[0020] 3) The first coating: Step 2) The stirred slurry is pumped into the candle filter for the first coating, the coating time is 10 minutes, and all the filter aids are evenly adhered to the filter rod superior;

[0021] 4) add filter aid: the slurry obtained in step 3) enters the additive tank again, and now add 15kg perlite filter aid;

[0022] 5) The second coating: the slurry with added filter aid is pumped into the candle filter again for the second coating, the coating time is 15 minutes, and all the filter aids are evenly adhered to the filter rod;

[0023] 6) Release the finally obtained clarified liquid.

[0024] 7) Take a sample of the filtered product and let it stand to observe the precipitation situation. At the same time, take a sample to detect the corresponding physical and chemical indic...

Embodiment 2

[0026] The difference between embodiment 2 and embodiment 1 is that the raw material soy sauce and the filter aid are added in different ratios, wherein the raw material soy sauce is 400KG, the filter aid added for the first time is 20KG, and the filter aid added for the second time is 20KG.

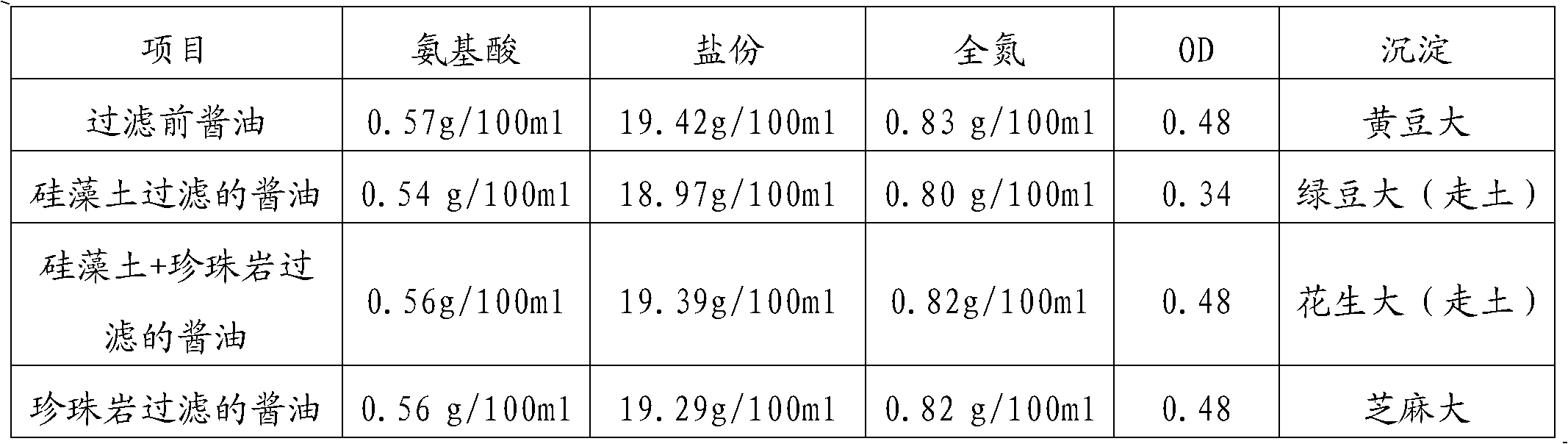

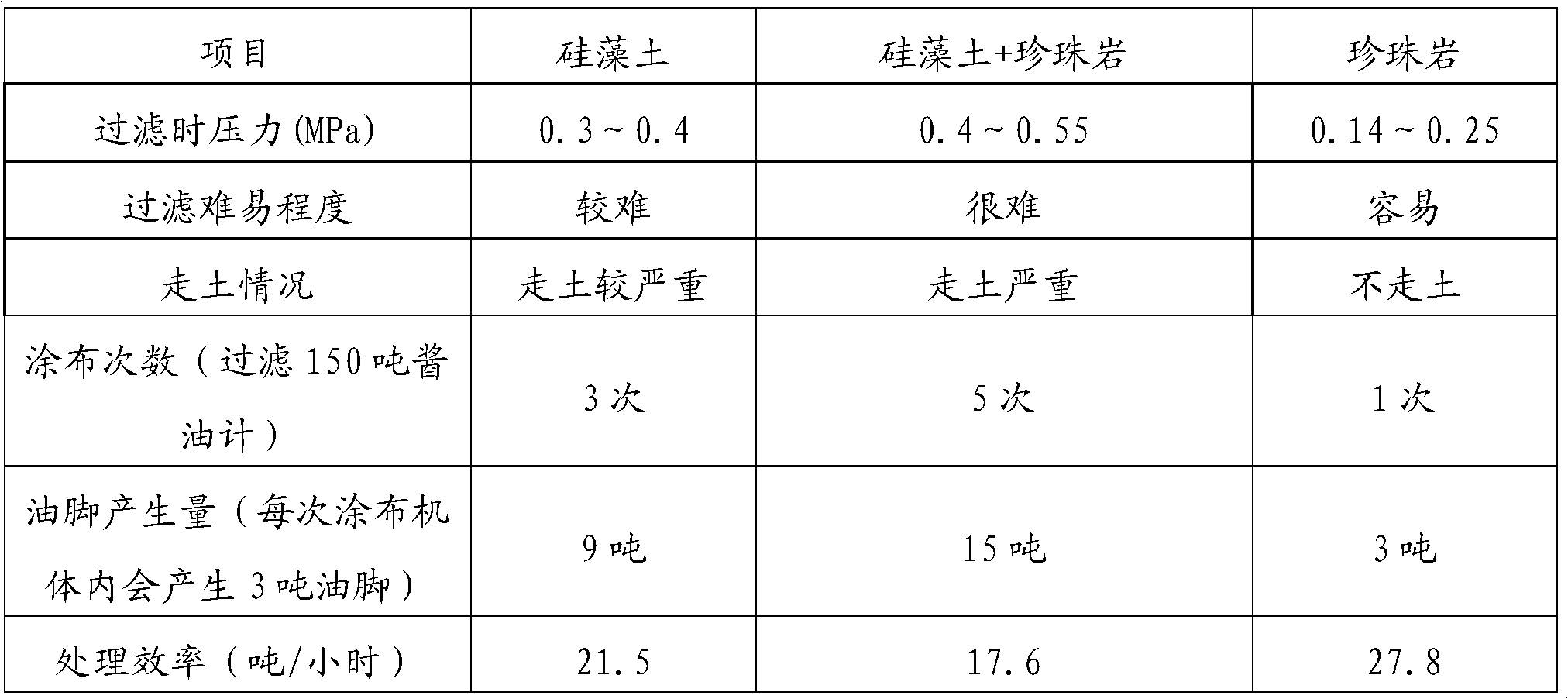

[0027] Table 1 is a comparison of the effects of different filtration methods (both using candle filters and different filter aids) on soy sauce indicators. In the comparative example using diatomite + perlite as filter aids, diatomite and perlite are each 50% by weight.

[0028] Table 1

[0029]

[0030] illustrate:

[0031] ① Compared with the index of soy sauce before filtration, the soy sauce filtered with diatomaceous earth has different degrees of loss in amino acid, salt, total nitrogen, and OD value (soy sauce color), and the loss of OD value is the largest. The rate reached 29%, indicating that the color of the product became lighter, and the phenomenon of "draining" appear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com