Method for regenerating activated carbon by steam

A technology of activated carbon and steam, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc. It can solve problems affecting the adsorption performance of regenerated carbon, the decrease of mechanical strength of regenerated carbon, and the change of chemical structure of carbon surface, so as to ensure the mechanical strength and surface properties, reducing the effect of reaction and reducing carbon loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for steam regeneration activated carbon, its main scheme comprises:

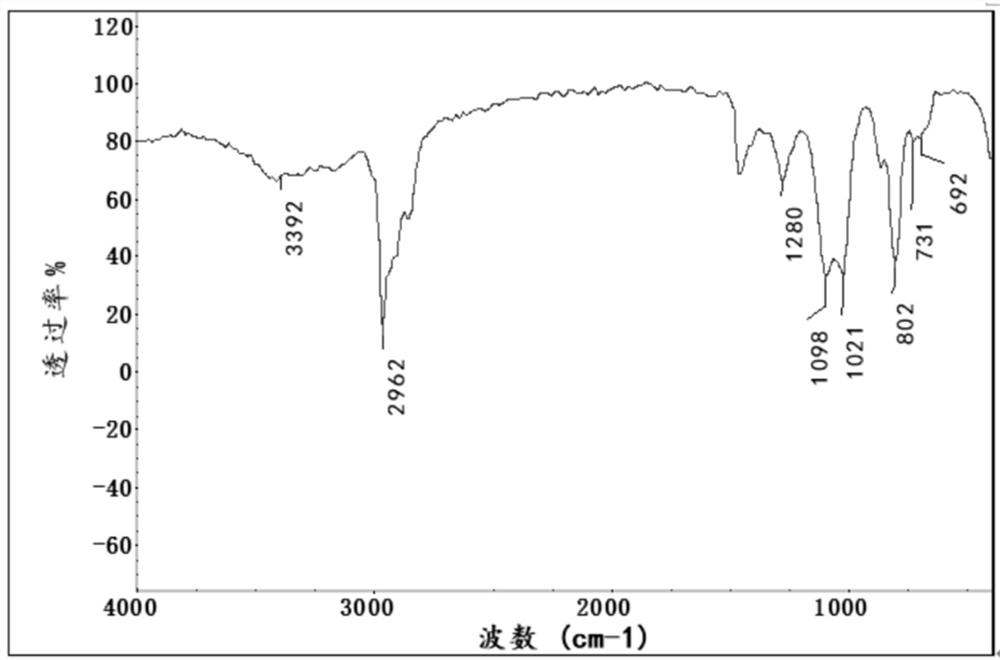

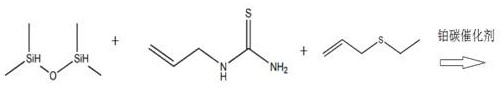

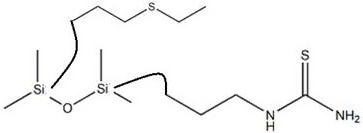

[0030] Step 1. Charcoal drying, put the waste activated carbon into the hopper, add 0.01% silyl sulfide inhibitor, mix evenly, then transfer to the drying furnace, control the temperature at 80°C and dry it into dry carbon powder;

[0031] Step 2, heat regeneration, transport the dried dry charcoal powder to the boiling activation furnace, and use the high-temperature medium gas to blow the charcoal powder for 12s to obtain the regenerated charcoal powder and furnace gas; it is characterized in that the high-temperature medium gas contains mole 1% water vapor for inhibiting gas;

[0032] Step 3: Collect the regenerated carbon, introduce the regenerated carbon powder and furnace gas into the separator, separate the regenerated activated carbon and furnace gas, collect the regenerated activated carbon in the hopper and cool to 100°C to discharge; after the furnace gas is separated, reheat it th...

Embodiment 2

[0042] A method for steam regeneration activated carbon, its main scheme comprises:

[0043] Step 1. Charcoal drying, put the waste activated carbon into the hopper, add 0.04% silyl sulfide inhibitor, mix evenly, then transfer to the drying furnace, control the temperature at 100 ℃ and dry into dry carbon powder;

[0044] Step 2, heat regeneration, transport the dried dry charcoal powder to the boiling activation furnace, and use the high-temperature medium gas to boil the charcoal powder for 24s to obtain the regenerated charcoal powder and furnace gas; it is characterized in that the high-temperature medium gas contains mole 10% water vapor suppressed gas;

[0045] Step 3. Collect the regenerated carbon, introduce the regenerated carbon powder and furnace gas into the separator, separate the regenerated activated carbon and furnace gas, collect the regenerated activated carbon in the hopper and cool to 130°C for discharge; after the furnace gas is separated, reheat it throug...

Embodiment 3

[0056] A method for steam regeneration activated carbon, its main scheme comprises:

[0057] Step 1. Charcoal drying, put the waste activated carbon into the hopper, add 0.08% silyl sulfide inhibitor, mix evenly, then transfer to the drying furnace, control the temperature at 120°C and dry into dry carbon powder;

[0058] Step 2, heat regeneration, transport the dried dry charcoal powder to the boiling activation furnace, and use the high-temperature medium gas to blow the charcoal powder for 30 seconds to obtain the regenerated charcoal powder and furnace gas; it is characterized in that the high-temperature medium gas contains mole 20% water vapor suppressed gas;

[0059] Step 3. Collect the regenerated carbon, introduce the regenerated carbon powder and furnace gas into the separator, separate the regenerated activated carbon and furnace gas, collect the regenerated activated carbon in the hopper and cool to 150°C for discharge; after the furnace gas is separated, reheat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com