Method for preparing tung cell-based active carbon by zinc chloride chemical activation method

A chemical activation and zinc chloride technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of wasting biomass resources, increasing the production cost of tung oil, and increasing the cost of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

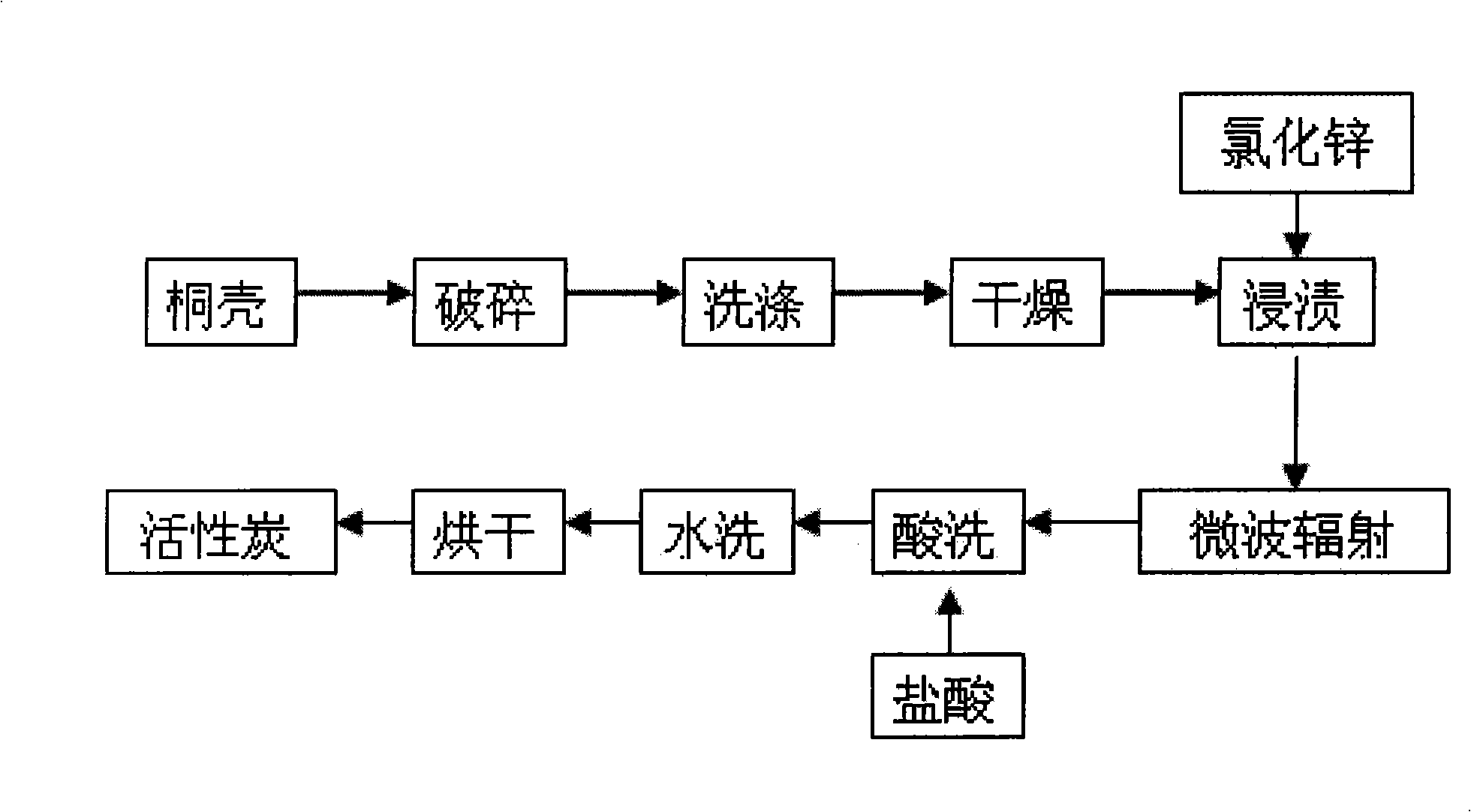

Method used

Image

Examples

Embodiment 1

[0013] 1) Add 50 grams of zinc chloride reagent and 100 grams of tung husks that have been washed, crushed and dried in distilled water to make a liquid, stir and soak at 80°C for 2 hours, then evaporate at 110°C water, and dried for 12 hours to form a zinc chloride / tung shell mixture for later use.

[0014] 2) Put the zinc chloride / tung husk mixture in a traditional heating high-temperature activation furnace, first pass nitrogen gas for 30 minutes at a rate of 300mL / min; , for activation, the activation time is 260min, and the primary product of activated carbon is obtained.

[0015] 3) Put the primary product of activated carbon in a high-temperature activation furnace heated by microwave radiation with controllable power, and first pass nitrogen gas at a rate of 200mL / min for 30 minutes, then set the microwave power at 500-650W under the protection of nitrogen atmosphere, and start microwave radiation Heating, microwave irradiation time is 15min, so that carbonization and...

Embodiment 2

[0019] 1) Add 50 grams of zinc chloride reagent and 150 grams of tung husks that have been washed, crushed and dried in distilled water to make a liquid, stir and soak at 80 ° C for 2 hours, then evaporate at 100 ° C water, and dried for 10 hours to form a zinc chloride / tung shell mixture for later use.

[0020] 2) Put the zinc chloride / tung husk mixture in a traditional heating high-temperature activation furnace, and first pass nitrogen gas at a rate of 300mL / min for 30min; then, under the protection of a nitrogen atmosphere, raise the temperature to 650 ℃, for activation, the activation time is 160min, the zinc chloride / tung shell mixture is subjected to carbon activation reaction, and the primary product of activated carbon is obtained.

[0021] 3) Place the primary product of activated carbon in a high-temperature activation furnace heated by microwave radiation with controllable power. First, nitrogen gas is introduced at a rate of 250 mL / min for 30 minutes. Then, under ...

Embodiment 3

[0025] 1) Add 50 grams of zinc chloride reagent and 30 grams of tung husks that have been washed, crushed and dried in distilled water to make a liquid, stir and soak at 80°C for 2 hours, then evaporate at 100°C water, and dried for 11 hours to form a zinc chloride / tung shell mixture for later use.

[0026] 2) Put the zinc chloride / tung husk mixture in a traditional heating high-temperature activation furnace, first pass nitrogen gas at a rate of 300mL / min for 30min; then, under the protection of nitrogen atmosphere, increase the temperature to 900 ℃, for activation, the activation time is 30min, the zinc chloride / tung shell mixture is subjected to carbon activation reaction, and the primary product of activated carbon is obtained.

[0027] 3) Place the primary product of activated carbon in a high-temperature activation furnace heated by microwave radiation with controllable power. First, nitrogen gas is introduced at a rate of 250mL / min for 30 minutes. Then, under the protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com