Method for preparing high-purity zinc oxide by using zinc-acetate-carrying waste activated carbon

A technology of waste activated carbon and zinc acetate, which is applied in the field of comprehensive recycling and utilization of waste resources, can solve the problems of high thermal regeneration temperature, complicated processing procedures, and long processing time, and achieve high quality, reduce environmental pollution, and strengthen practical and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for preparing high-purity zinc oxide by using waste activated carbon loaded with zinc acetate, its concrete steps are as follows:

[0022] (1) Using waste activated carbon loaded with zinc acetate as raw material, microwave regeneration treatment is carried out by controlling the heating rate of an industrial microwave oven at 10°C / min, the microwave roasting temperature at 400°C, and the holding time of 40 minutes; the waste activated carbon loaded with zinc acetate includes the following mass percentages Composition: Carbon 60%, Zn5%, P1%, Na, Ca, Al, Si impurity elements accounted for 0%;

[0023] (2) After the regeneration treatment in step (1), it is naturally cooled at room temperature to produce a product in which the upper layer is zinc oxide and the lower layer is regenerated activated carbon, and finally separated to obtain zinc oxide and regenerated activated carbon.

[0024] The iodine adsorption value of the regenerated activated carbon obtained ...

Embodiment 2

[0026] The method for preparing high-purity zinc oxide by using waste activated carbon loaded with zinc acetate, its concrete steps are as follows:

[0027] (1) Using waste activated carbon loaded with zinc acetate as raw material, microwave regeneration treatment is carried out by controlling the heating rate of an industrial microwave oven at 60°C / min, the microwave roasting temperature at 600°C, and the holding time for 30 minutes; the waste activated carbon loaded with zinc acetate includes the following mass percentages Components: Carbon 75%, Zn8%, P2%, Na, Ca, Al, Si impurity elements accounted for 1%;

[0028] (2) After the regeneration treatment in step (1), it is naturally cooled at room temperature to produce a product in which the upper layer is zinc oxide and the lower layer is regenerated activated carbon, and finally separated to obtain zinc oxide and regenerated activated carbon.

[0029] The iodine adsorption value of the regenerated activated carbon obtained ...

Embodiment 3

[0031] The method for preparing high-purity zinc oxide by using waste activated carbon loaded with zinc acetate, its concrete steps are as follows:

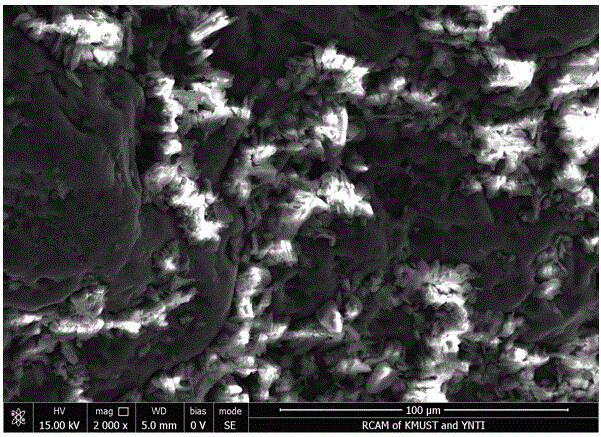

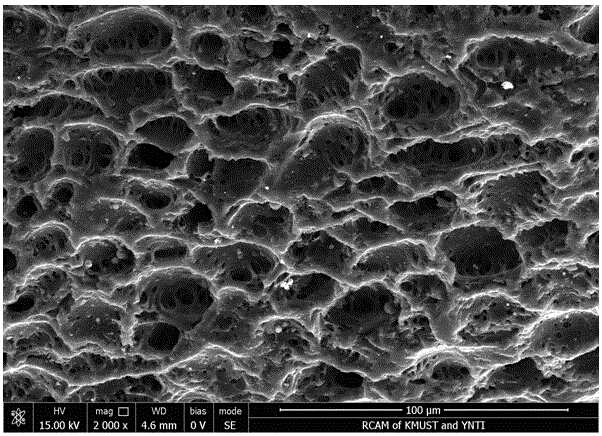

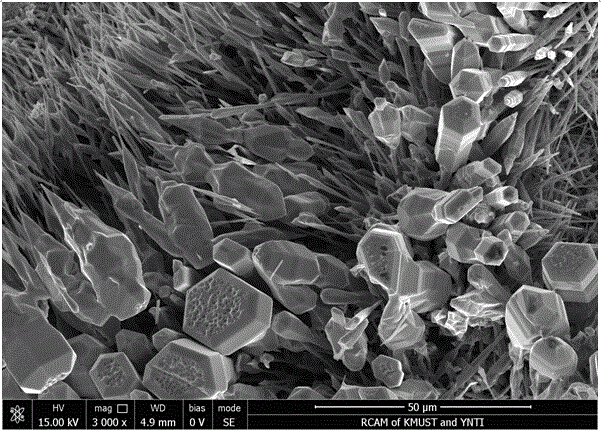

[0032] (1) Using waste activated carbon loaded with zinc acetate as raw material, the heating rate of industrial microwave ovens is controlled to 110°C / min, and the microwave roasting temperature is 800°C , The holding time is 20min for microwave regeneration treatment; the waste activated carbon loaded with zinc acetate includes the following mass percentage components: carbon 85%, Zn10%, P3%, Na, Ca, Al, Si impurity elements account for 2%, and the waste activated carbon loaded with zinc acetate SEM picture as figure 1 shown;

[0033] (2) After the regeneration treatment in step (1), it is naturally cooled at room temperature to produce a product in which the upper layer is zinc oxide and the lower layer is regenerated activated carbon, and finally separated to obtain zinc oxide and regenerated activated carbon.

[0034] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com