Aqueous rechargeable magnesium/zinc ion capacitor battery

A capacitive battery and zinc ion technology, applied in the field of electrochemistry, can solve problems such as mismatch between energy peak output and energy needs, low energy storage density of supercapacitors, and potential safety hazards, etc., to achieve long cycle life, high energy density, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of the pole piece: The electrode paste is made by mixing positive and negative active materials, binders, and conductive electrodes, and the electrode paste is coated (with a thickness of 400 μm to 1000 μm) on the current collector, and vacuumed at 100 ° C. After drying for 20 hours, press the coated pole pieces under a certain pressure (0-10MPa) and cut them into 1cm×1cm pole pieces.

[0027] Assembly of the sandwich structure: Assemble a battery pack similar to a sandwich structure according to the sequence of titanium frame, positive electrode sheet, diaphragm, negative electrode sheet, and titanium frame, and soak in the electrolyte system containing magnesium ions or zinc ions.

[0028] In order to better illustrate the present invention, a more detailed description is given below with specific examples.

Embodiment 1

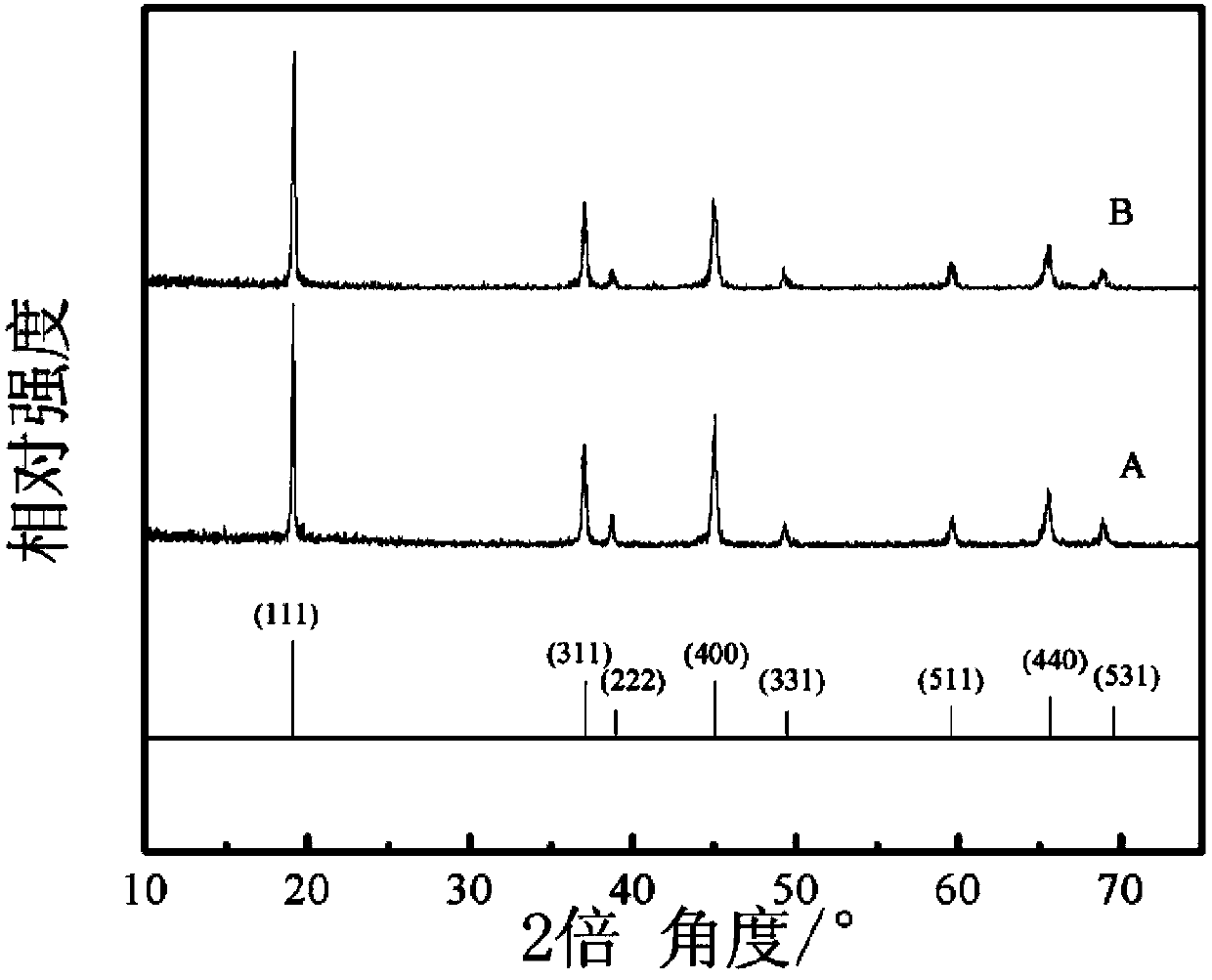

[0030] (1) Mix LiMn with a molar ratio of 1:2 2 o 4 and H 2 SO 4 Fully magnetically stirred at 50°C for 3 hours, after decantation, ultrasonication, centrifugation, filtration, drying, grinding, etc., the product λ-MnO was finally prepared 2 , XRD characterization as figure 1 As shown in A;

[0031] (2) Add λ-MnO 2, Ketjen black, and polyvinylidene fluoride are fully mixed under magnetic stirring according to the mass ratio of 8:1:1 to form a slurry, which is evenly coated on the nickel sheet of the current collector, dried in a vacuum oven at 100°C and then cut into a slurry. electrode.

[0032] (3) The coating thickness of the pole piece is 400μm, the area of each pole piece is 1cm×1cm, and the coating amount on one side of the electrode is 5mg / cm;

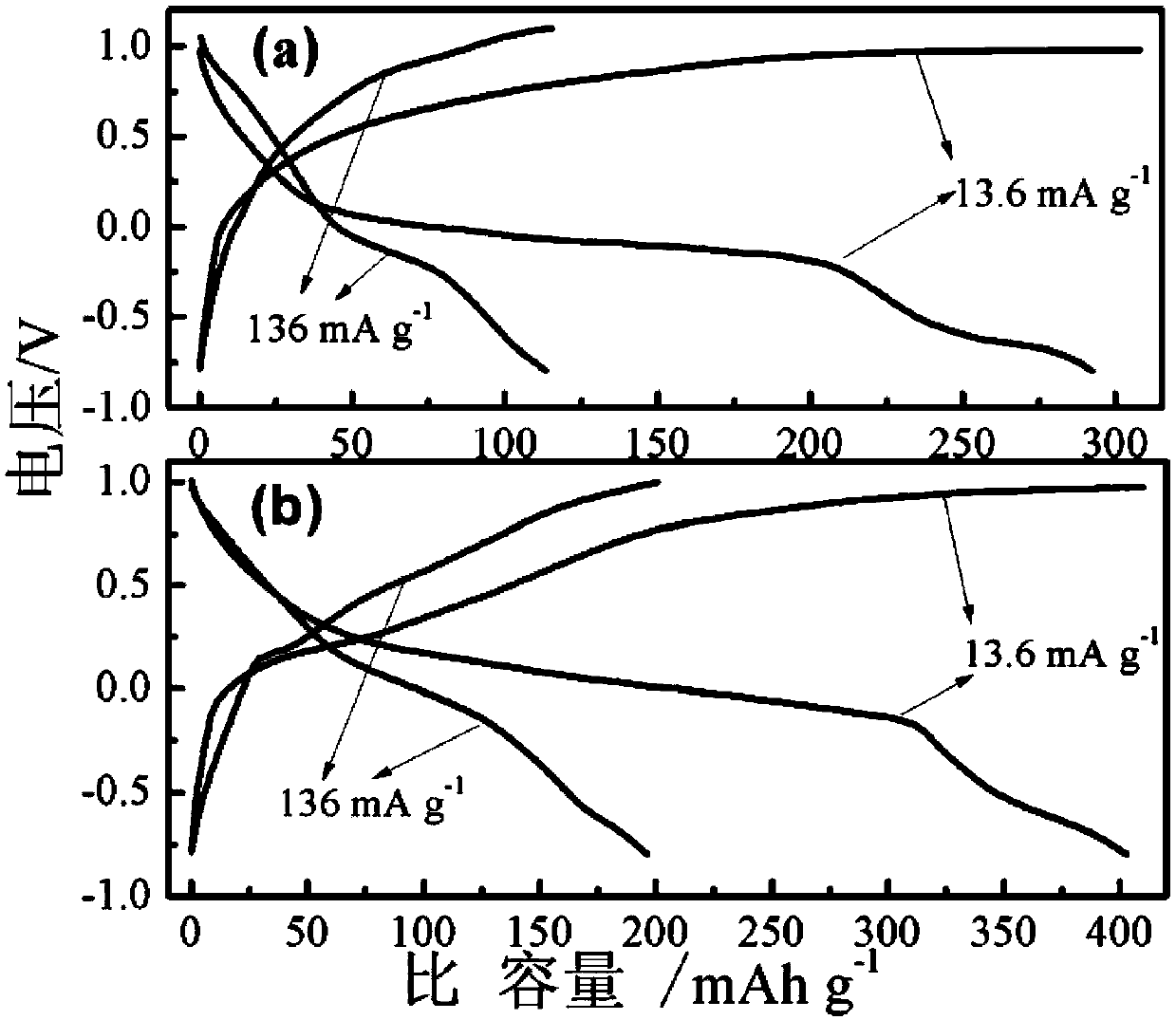

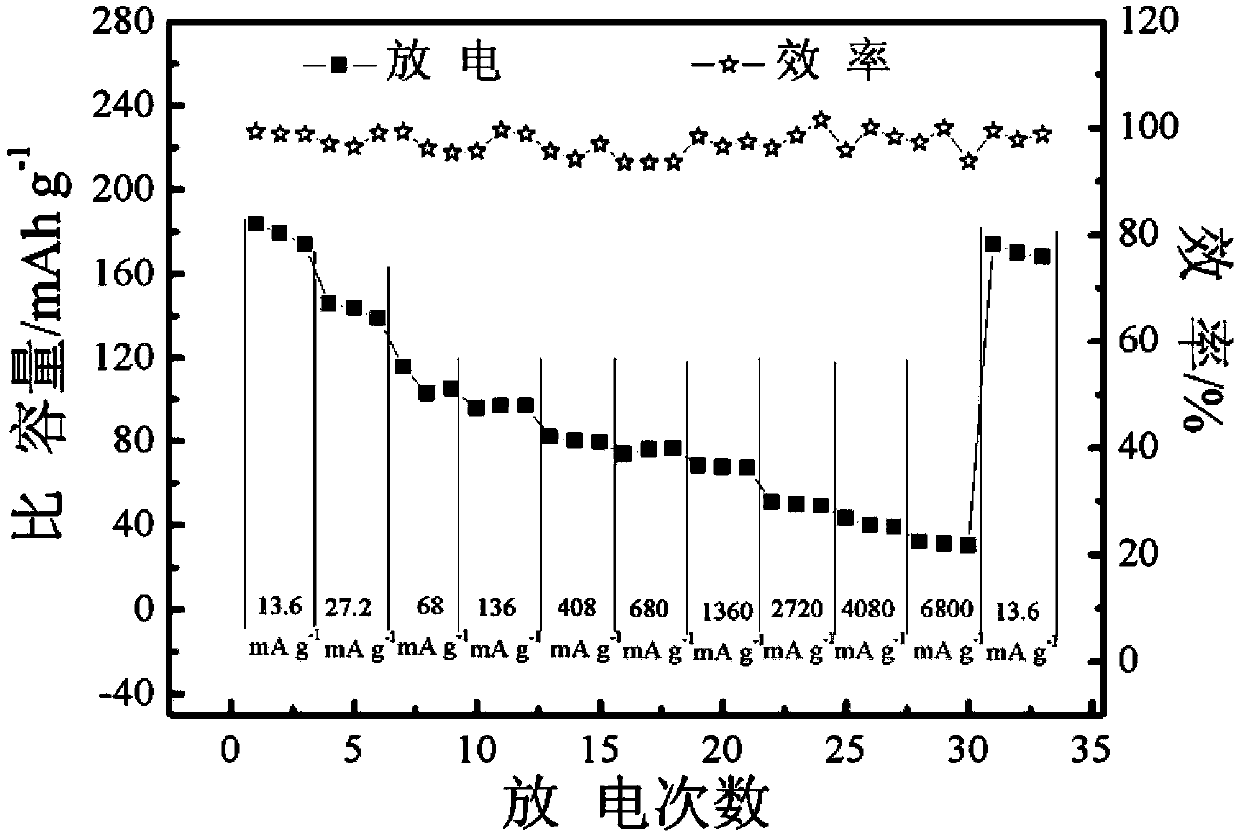

[0033] (4) The prepared electrode was used as the working electrode, the saturated calomel electrode and the platinum electrode were respectively used as the reference electrode and the counter electrode to form a three...

Embodiment 2

[0036] (1) Mix LiMn with a molar ratio of 1:2 2 o 4 and H 2 SO 4 Fully magnetically stirred at 50°C for 12 hours, after decantation, ultrasonication, centrifugation, filtration, drying, grinding, etc., the product λ-MnO was finally prepared 2 , XRD characterization as figure 1 As shown in B;

[0037] (2) Add λ-MnO 2 , acetylene black, and polyvinylidene fluoride are fully mixed under magnetic stirring according to the mass ratio of 8:1:1 to form a slurry, which is evenly coated on the nickel foam of the current collector, dried in a vacuum oven at 100°C and then cut into a slurry. electrode.

[0038] (3) The coating thickness of the pole piece is 500μm, the area of each pole piece is 1cm×1cm, and the coating amount on one side of the electrode is 6mg / cm;

[0039] (4) The prepared electrode was used as the working electrode, the saturated calomel electrode and the platinum electrode were respectively used as the reference electrode and the counter electrode to form a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com