Metal monoatom-doped carbon nanomaterial catalytic carrier, and preparation method and application thereof

A nano-carbon material and catalytic carrier technology, applied in the field of electrochemical energy, can solve the problems of poor high-rate charge and discharge performance, damage to electrode structure, and inability to achieve practicality, and achieve improved electrochemical performance, rich porous structure, and rapid charge and discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides the preparation method of the metal single atom doped nano-carbon material catalytic carrier, including:

[0043] Mixing the nitrogen-containing carbon precursor and the metal catalyst precursor and dispersing them in a solvent to form a uniform mixed solution to form a carbon material precursor loaded with metal ions,

[0044] Annealing is performed on the precursor to obtain the metal single atom doped nano-carbon material catalytic carrier.

[0045] Further, the method includes:

[0046] Coating carbon materials with nitrogen-containing organics to form a nitrogen-containing carbon precursor with a core-shell structure,

[0047] mixing the nitrogen-containing carbon precursor and the metal catalyst precursor and uniformly dispersing in a solvent to form a mixed solution, and then removing the solvent in the mixed solution to obtain a solid mixture,

[0048] Under a protective atmosphere, heat-treat the solid mix...

Embodiment 1

[0071] Example 1: Graphene oxide powder and carbon nanotube powder are respectively prepared in a tube furnace for pyrolysis ammonia to obtain nitrogen-doped graphene (NG) and nitrogen-doped carbon nanotubes (NCNT), which are mixed together and ultrasonically dispersed , Slowly add the aniline solution dropwise, and adjust the pH value to between 1 and 2 with hydrochloric acid. Under ice-water bath conditions, an appropriate amount of ammonium persulfate was slowly added dropwise and stirred for 24 hours. After the reaction was completed, the mixture was filtered, washed, and vacuum-dried to obtain a PANI-coated NG-NCNT material (NG-NCNT@PANI). Then the composite material and metal cobalt precursor (such as soluble cobalt salt, etc.) are dispersed in ethanol, and then the ethanol is volatilized, and the obtained solid powder is placed in a program-controlled tube furnace for heat treatment. The heating rate was raised to 700°C and kept for 120 min at a heating rate of 1 / min, a...

Embodiment 2

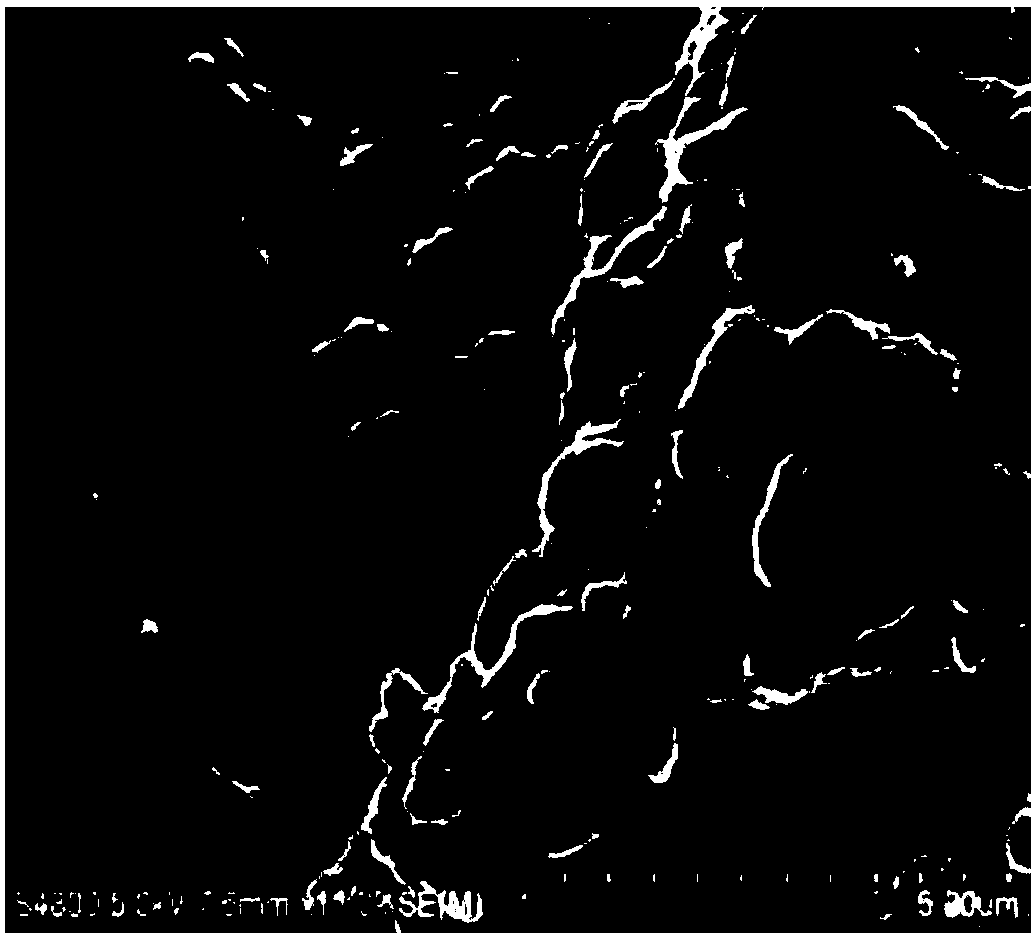

[0072] Embodiment 2: NG~NCNT@PANI, commercial lithium sulfide (Li 2 S) Add it into a certain amount of absolute ethanol in a mass ratio of 1:3 and mix evenly. After 12 hours of magnetic stirring, the ethanol is rapidly volatilized at a temperature of 90° C., and the obtained solid powder is transferred to a corundum crucible. In an atmosphere of argon, the composite material was placed in a program-controlled tube furnace for heat treatment, and the temperature was raised to 700 °C at a heating rate of 3 °C / min and kept for 120 min, and then naturally cooled to room temperature to obtain a composite material (Li 2 S@NC). From figure 2 It can be seen that the flaky lithium sulfide is uniformly distributed in the carbon material skeleton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com