Preparation method of microalga-based biochar material for heavy metal ion adsorption

A technology of heavy metal ions and biochar, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor adsorption effect of heavy metal ions, and achieve the effects of high photosynthesis efficiency, controllable morphology, and short growth cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

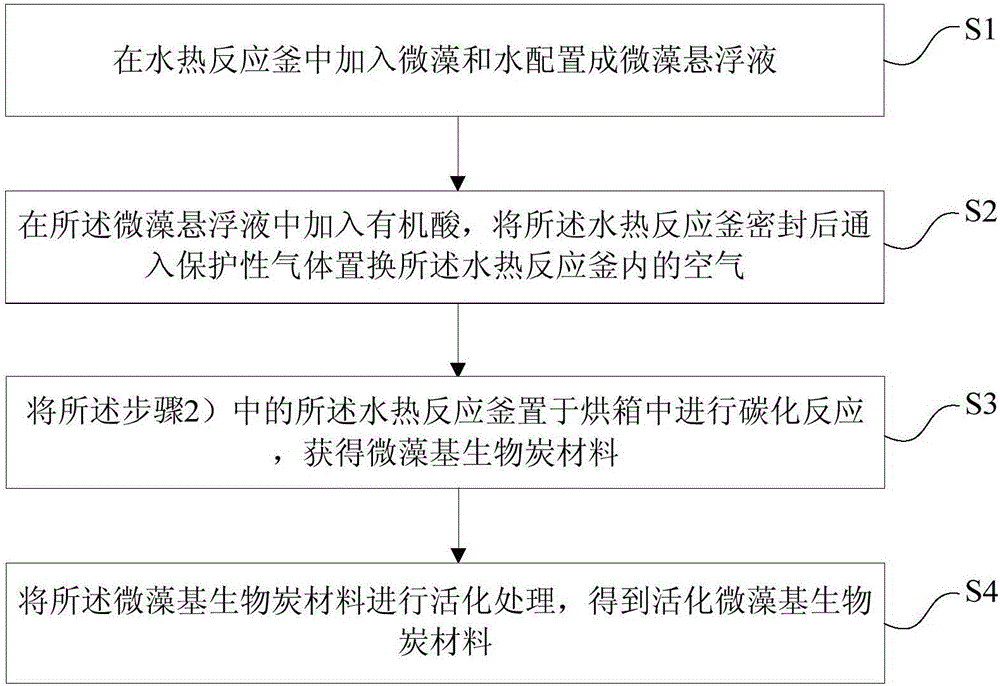

[0036] The invention provides a method for preparing a microalgae-based biochar material for heavy metal ion adsorption, such as figure 1 As shown, the preparation method at least includes the following steps:

[0037] S1: add microalgae and water into the hydrothermal reactor to prepare microalgae suspension;

[0038] S2: adding an organic acid to the microalgae suspension, sealing the hydrothermal reaction kettle, and introducing a protective gas to replace the air in the hydrothermal reaction kettle;

[0039]S3: placing the hydrothermal reaction kettle in the step 2) in an oven for carbonization reaction to obtain a microalgae-based biochar material;

[0040] S4: Activating the microalgae-based biochar material to obtain an activated microalgae-based biochar material.

Embodiment 1

[0043] Accurately weigh 1.0g of freeze-dried green algae, 50ml of deionized water, add it to a 100ml hydrothermal reaction kettle, 1g of oxalic acid, ultrasonic for 10min, seal the reaction kettle and pass it into N 2 The air in the kettle was replaced, and finally placed in an oven at 180°C for carbonization for 4 hours, cooled, filtered, washed, dried, and then vacuum-dried at 80°C for 12 hours to obtain a microalgae-based biochar material. 1g of the microalgae-based biochar material and 0.01g·ml -1 The KOH solution was mixed and placed in a tubular reactor for activation at 400°C for 1 hour to obtain activated microalgae-based biochar materials.

Embodiment 2

[0045] Accurately weigh 2.0g of Scenedesmus after freeze-drying treatment, add 50ml of deionized water into a 100ml hydrothermal reaction kettle, and add 1g of acrylic acid, ultrasonic for 10min, seal the reaction kettle and pass it into N 2 Replace the air in the kettle, and finally place it in an oven at 180°C for 8 hours of carbonization, cool, filter, wash, dry, and then vacuum-dry at 80°C for 12 hours to obtain a microalgae-based biochar material. 1g of the microalgae-based biochar material and 0.1g·ml -1 The KOH solution was mixed and placed in a tubular reactor for activation at 600°C for 2 hours to obtain activated microalgae-based biochar materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com