Preparing method for three dimensional bacterial cellulose-derived carbon nano fiber/metal particle composite aerogel

A technology of bacterial cellulose and carbon nanofibers, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as uneven loading of metal particles, and achieve controllable loading and uniform distribution , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1), cut the bacterial cellulose hydrogel into rectangles (1*4*2cm 3 ), immersed in 0.2M cobalt chloride solution for 12h, heated to 90°C in a water bath, and kept for 2h; then the hydrogel was transferred to 1M sodium hydroxide solution at 90°C for 3h, and after natural cooling Rinse thoroughly with deionized water until neutral. The resulting composite hydrogel was frozen by immersion in liquid nitrogen, and then vacuum freeze-dried.

[0027] 2) The product obtained in step 1 was pyrolyzed at 900° C. for 2 hours under a nitrogen atmosphere, and cooled naturally to obtain a three-dimensional bacterial cellulose-derived carbon nanofiber / cobalt composite airgel.

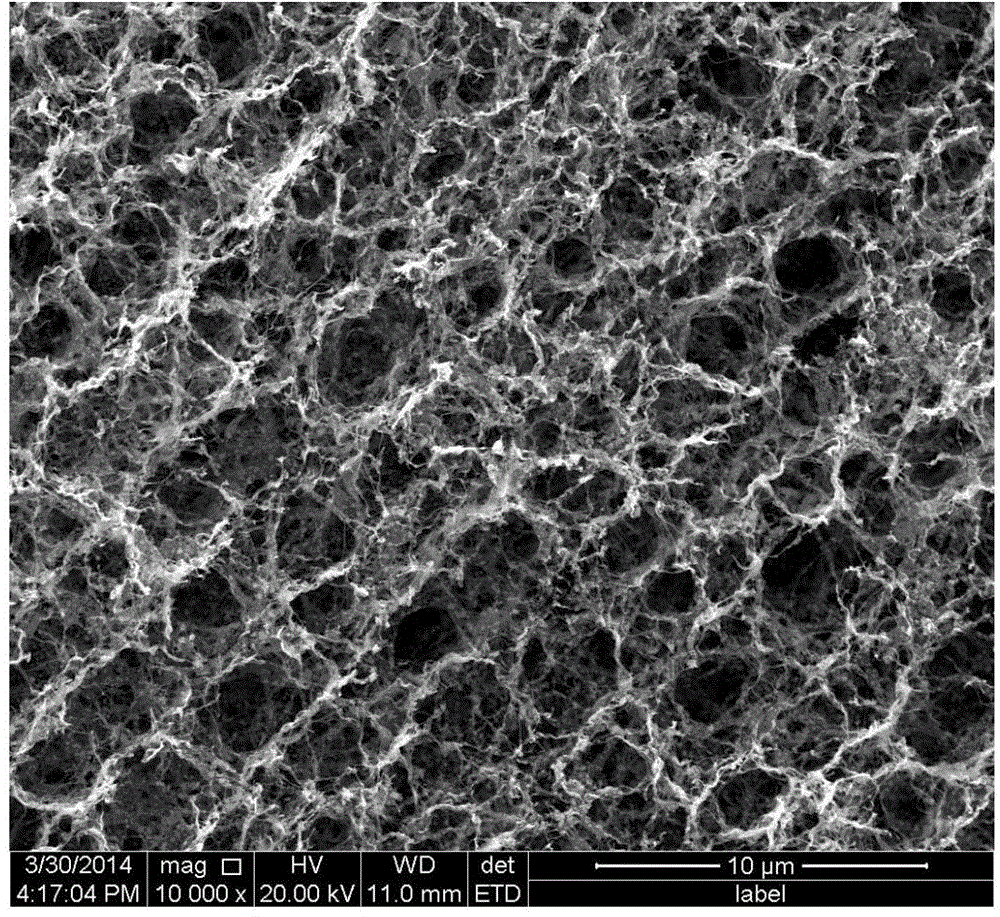

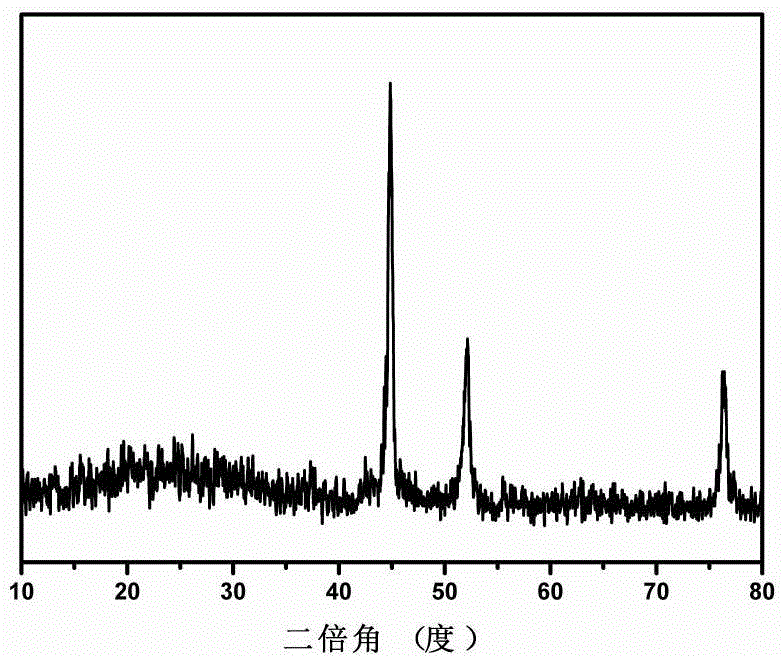

[0028] The prepared product is a macroscopic three-dimensional bulk material, such as figure 1 Shown; The three-dimensional composite airgel has a porous network cross-linked structure, the diameter of carbon nanofibers is about 30-50nm, and the cobalt nanospheres with a particle diameter of about 100nm are un...

Embodiment 2

[0030] 1), cut the bacterial cellulose hydrogel into rectangles (1*2*2cm 3 ), soaked in 0.1M cobalt acetate solution for 8h, heated to 85°C in a water bath, and kept for 2h, then transferred the hydrogel to 90°C 1M potassium hydroxide solution for 6h, cooled naturally and used Rinse thoroughly with deionized water until neutral. The resulting composite hydrogel was frozen by immersion in liquid nitrogen, and then vacuum freeze-dried.

[0031] 2) The product obtained in step 1 was pyrolyzed at 800° C. for 2 hours in an argon atmosphere, and cooled naturally to obtain a three-dimensional bacterial cellulose-derived carbon nanofiber / cobalt composite airgel.

[0032] The prepared composite airgel is also a block structure. The airgel maintains a three-dimensional porous network structure and has randomly distributed macropores and mesopores. The cobalt nanospheres are tightly loaded on the carbon nanofibers and distributed uniformly. The diameter of the cobalt nanospheres is sli...

Embodiment 3

[0034] 1), cut the bacterial cellulose hydrogel into rectangles (1*4*2cm 3 ), immersed in 0.2M ferrous sulfate solution for 12h, heated to 90°C in a water bath, and kept for 2h, then transferred the hydrogel to 1M sodium bicarbonate solution at 80°C for 3h, and cooled naturally Rinse thoroughly with deionized water until neutral. The resulting composite hydrogel was frozen by immersion in liquid nitrogen, and then vacuum freeze-dried.

[0035] 2) The product obtained in step 1 was pyrolyzed at 900° C. for 2 hours under an argon atmosphere, and cooled naturally to obtain a three-dimensional bacterial cellulose-derived carbon nanofiber / iron composite airgel.

[0036] The prepared three-dimensional bacterial cellulose-derived carbon nanofiber / iron composite airgel is also a bulk material, in which the intercrosslinked carbon nanofibers are interlinked to form a three-dimensional porous network structure, and the iron nanospheres are uniformly loaded on the carbon on nanofibers,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com