Preparation method of biomass activated carbon rich in nitrogen and oxygen

A technology for nitrogen-containing substances and biomass is applied in the field of special functional activated carbon materials, which can solve the problems of cumbersome process and unfavorable industrial production, achieve wide application prospects and improve wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

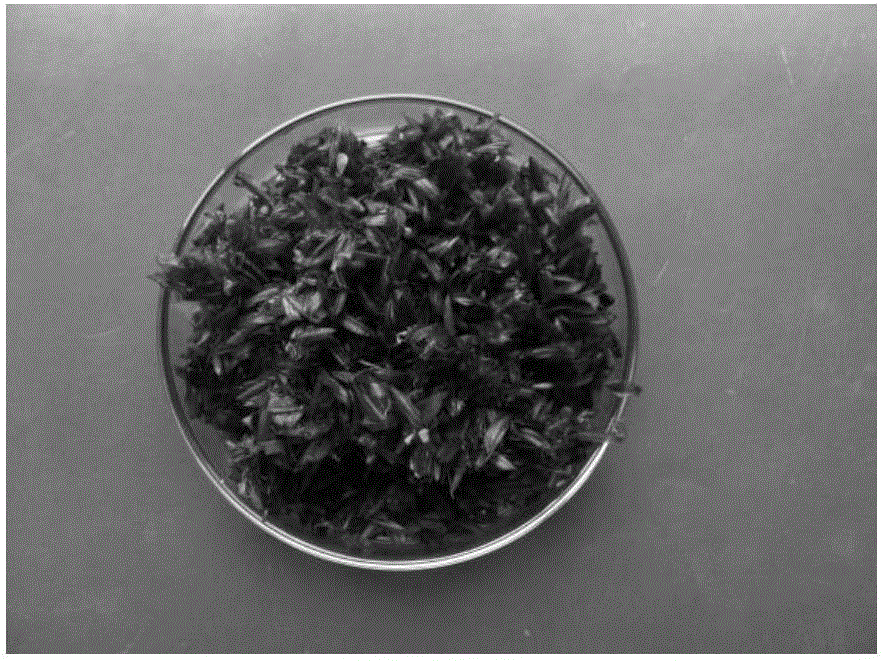

[0021] Add 10g of wheat husks into 100g of a mixed solution containing 10% ammonia by mass fraction and 5% potassium hydroxide by mass fraction, move it into a hydrothermal reaction kettle after fully soaking, and carry out hydrothermal reaction at 240 degrees for 2 hours. After the reaction is finished, cool to room temperature, and the product is taken out by filtration and dried, such as figure 1 As shown, the dried product was put into a high-temperature tube furnace, and reacted for 0.5 hours under the protection of nitrogen at 600 degrees Celsius. After the reaction is completed, the temperature is lowered to room temperature, and the product is taken out, washed repeatedly with deionized water, and dried to obtain sisal activated carbon fibers rich in nitrogen and oxygen. Such as figure 2 shown.

Embodiment 2

[0023] Add 3g of corn cobs to 60g of a mixed solution containing 30% ammonia by mass fraction and 10% potassium carbonate by mass fraction, move it into a hydrothermal reaction kettle after fully soaking, and carry out hydrothermal reaction at 180 degrees for 6 hours. After cooling to room temperature, the product was taken out by filtration and dried, then put into a high-temperature tube furnace, and reacted for 2 hours under the protection of nitrogen at 600°C. After the reaction is finished, cool down to room temperature, take out the product, wash it repeatedly with deionized water, and obtain corn cob activated carbon rich in nitrogen and oxygen after drying.

Embodiment 3

[0025] Add 10g of bamboo to 50g of a mixed solution containing 20% ammonia by mass fraction and 15% potassium hydroxide by mass fraction, move it into a hydrothermal reaction kettle after fully soaking it, and carry out hydrothermal reaction at 220 degrees for 4 hours. After cooling to room temperature, the product was taken out by filtration and dried, then put into a high-temperature tube furnace, and reacted for 1 hour under the protection of nitrogen at 800 degrees Celsius. After the reaction is finished, the temperature is lowered to room temperature, the product is taken out, washed repeatedly with deionized water, and bamboo activated carbon rich in nitrogen and oxygen is obtained after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com