Ceramsite for heavy metal wastewater treatment, preparation method and applications thereof

A technology for wastewater treatment and heavy metals, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of long biological treatment cycle, few engineering cases, and low efficiency. Achieve excellent heavy metal ion adsorption and reduction performance, easy to obtain raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

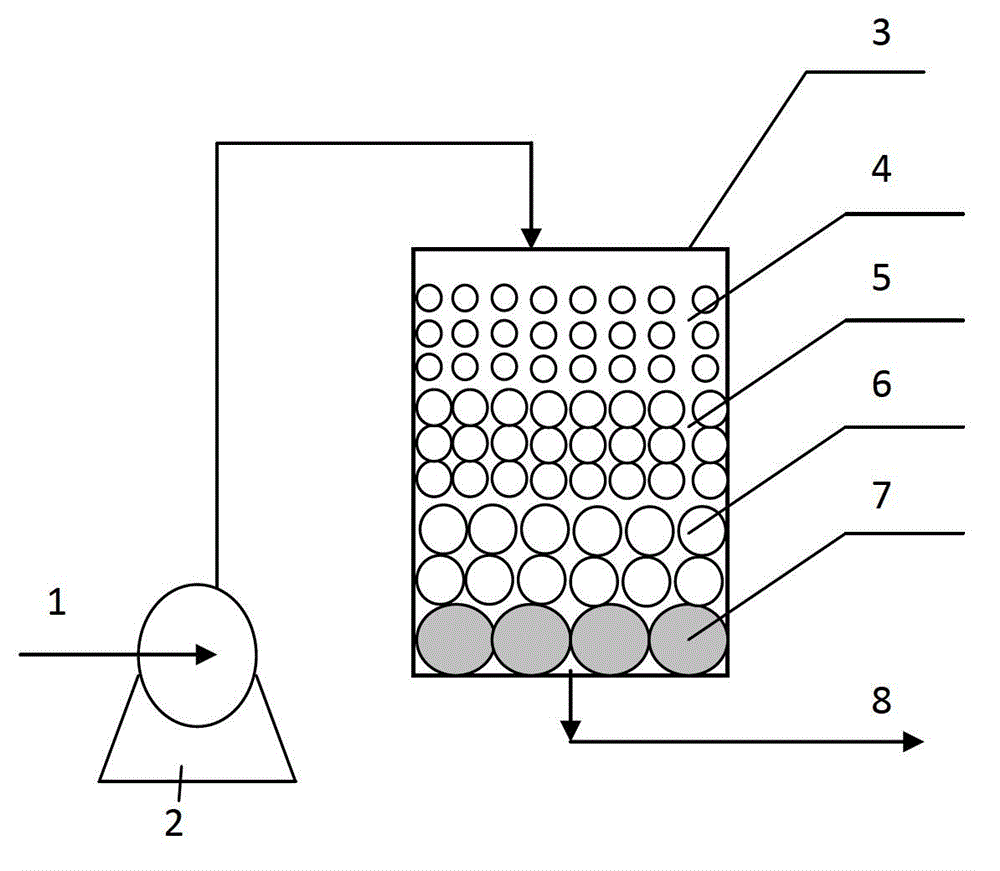

Image

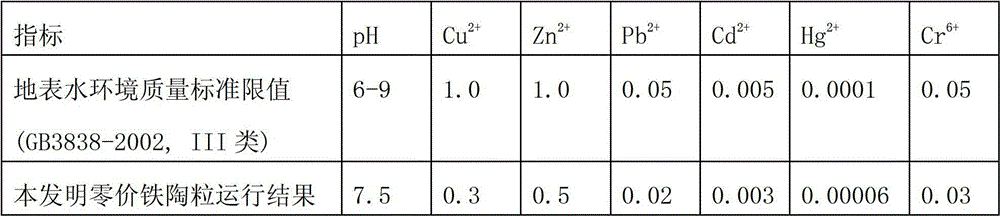

Examples

Embodiment 1

[0025] 1) Raw material pretreatment: After drying the raw material, pass through a 60-mesh sieve;

[0026] 2) Mixing of raw materials: Mix the raw materials evenly according to the following weight ratio: 80 kg of bentonite or kaolin; 10 kg of 200nm zero-valent iron powder; 10 kg of activated carbon powder;

[0027] 3) Granulation: add 20 kg of water to 100 kg of uniformly mixed raw materials, the amount of water added is 20% of the weight of the raw materials, stir and granulate to form a 5mm zero-valent iron ceramsite blank;

[0028] 4) Sintering: Dry the zero-valent iron ceramsite blank in a blast drying oven for 3 hours; then put it into an electric heating tube furnace and preheat it at a preheating temperature of 300°C for 15 minutes; Keep warm at 800°C for 1-3 hours; cool down to 150°C at a constant speed within 5 hours, and then slowly cool down to room temperature to obtain the desired ceramsite.

[0029] The use of the ceramsite in the present invention is mainly as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com