Preparation method and application of aminated graphene film

A technology of aminated graphene and graphene, applied in chemical instruments and methods, separation methods, adsorption water/sewage treatment, etc., can solve problems such as inability to achieve large-scale production, difficulty, and in the laboratory research stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

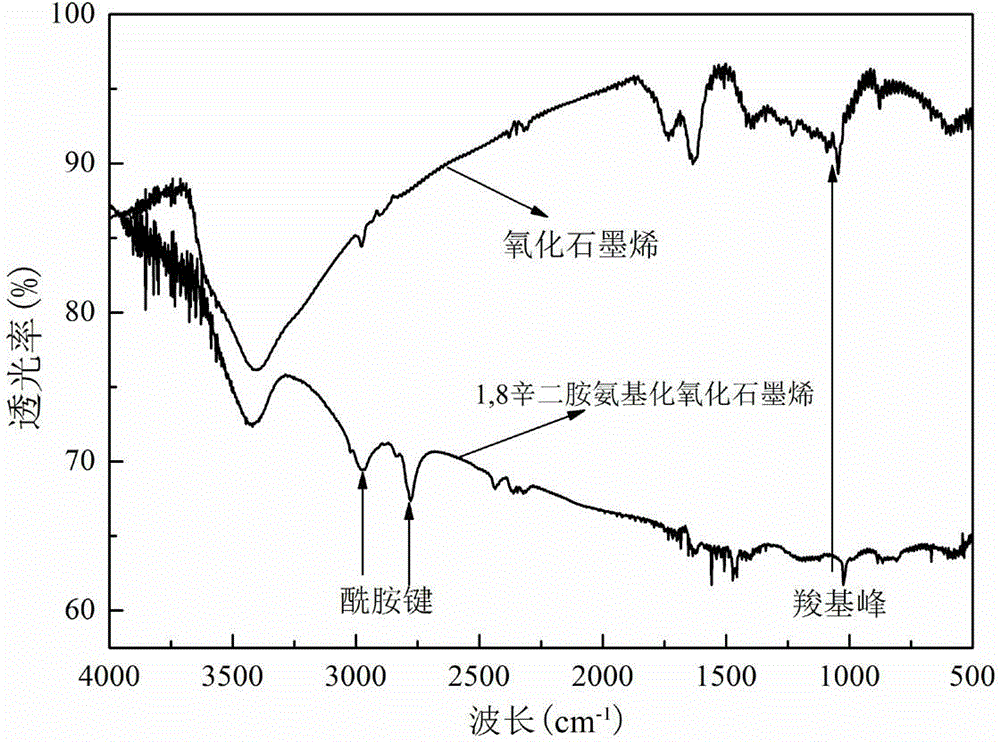

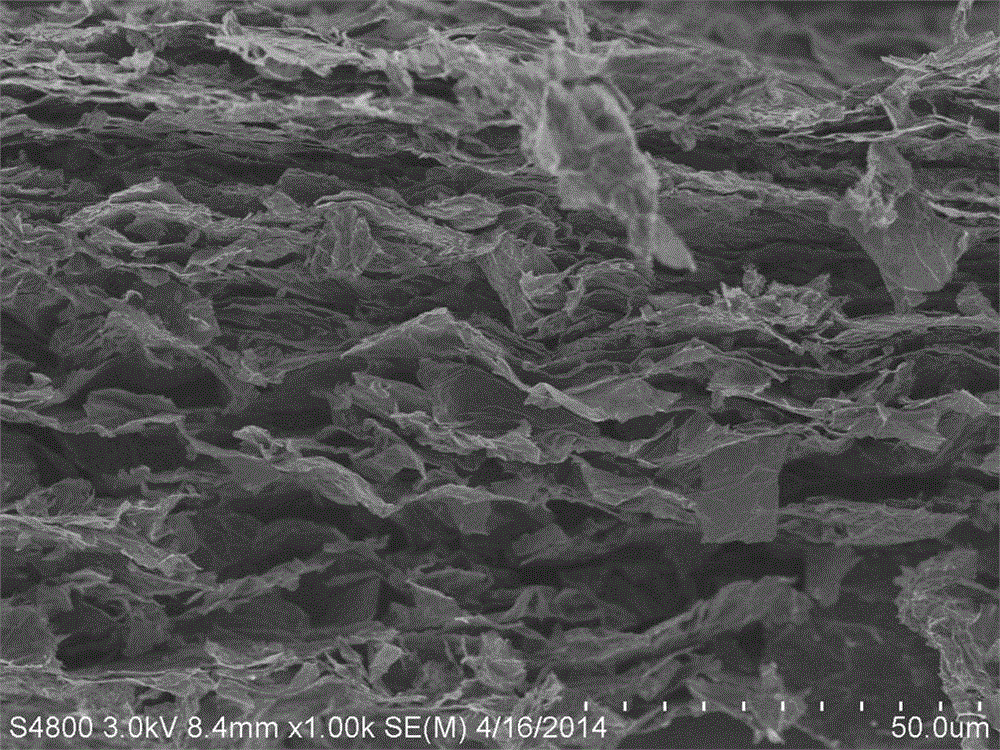

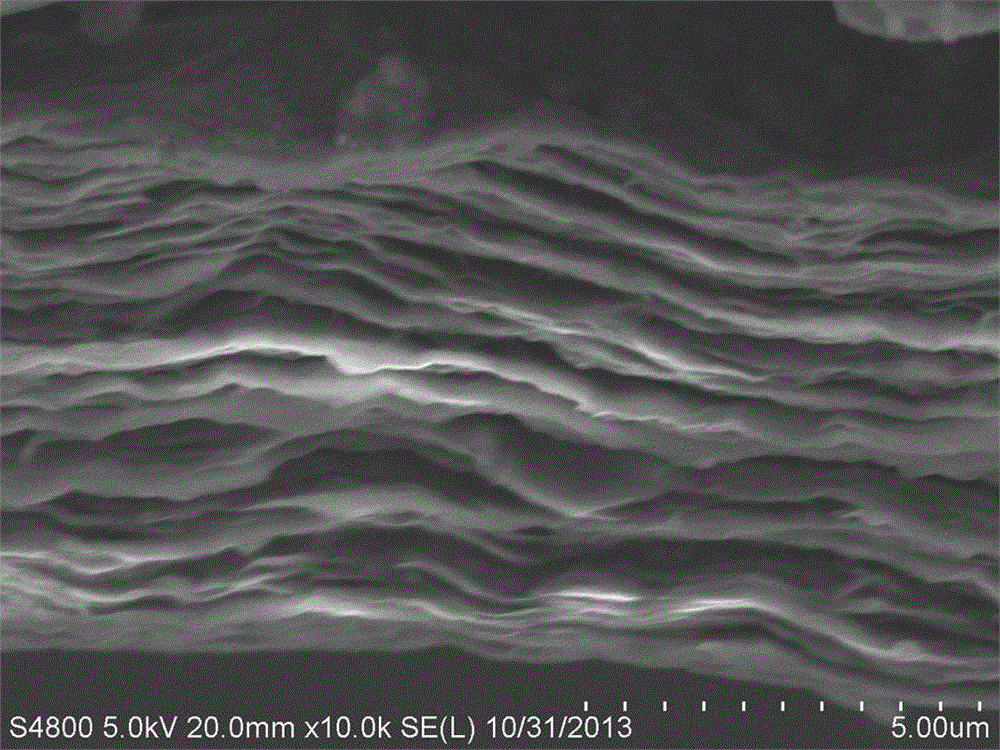

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of graphite oxide

[0031] Add 1 g of graphite to 100 ml of concentrated H 2 SO 4 (98%) solution, stirred in an ice bath for 30 min, then slowly added 1 g of potassium persulfate and 1.5 g of phosphorus pentoxide, stirred in an ice bath for 30 min; then reacted the solution in an oil bath at 80°C for 5 h, and Slowly transfer the solution to 300ml of distilled water, suction filter, and dry; put the dried pre-oxidized graphite in a dry beaker, add 100ml of concentrated sulfuric acid, stir in an ice bath, slowly add 4g of potassium permanganate, and stir for 30min Then put it in an oil bath at 35°C for 2 hours, slowly pour the reaction solution into 300ml distilled water, stir, cool for 1 hour, then slowly add 10ml hydrogen peroxide (30%) to the solution to obtain an orange-yellow solution; then add 500ml 5% HCl solution, let stand for 3h and pour out the supernatant to remove metal ions; then centrifuge and wash with deionized water to remove excess aci...

Embodiment 2

[0040] The preparation method of GO was the same as that in Example 1. Dried dimethylamide (DMF) with molecular sieves treated at 400°C for 2 hours for 2 hours, weighed 1 g of GO and dissolved it in the DMF solution to prepare a solution with a concentration of 50 mg / ml, and ultrasonically Disperse GO evenly; then invert the solution into a 250ml two-necked flask, add 1.5 g of dicyclohexylcarbodiimide, and stir the solution at 80°C for 10 h; then raise the temperature of the solution to 170°C, and evaporate the SO in the solution 2 and HCl gas, after the solution was cooled to 150°C, 1.5 g of 4-4-methine-bis(2-chloroaniline) was added to react for 36 h; then the solution was poured into ethanol and left to stand, and washed with deionized water by centrifugation product, and then put the product in a rotary evaporator and spin dry at 90°C to obtain graphene oxide grafted 4-4-methine-bis(2-chloroaniline).

[0041] The solution was prepared according to the mass ratio of 4-4-met...

Embodiment 3

[0044] The preparation method of GO is the same as that in Example 1. Dimethylamide (DMF) was dried with molecular sieves treated at 350°C for 2 hours for 3 hours, and 1 g of GO was weighed and dissolved in DMF solution to prepare a solution with a concentration of 20 mg / ml, and ultrasonically Disperse GO evenly; then invert the solution into a 250ml two-necked flask, add 0.75 g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, and stir the solution at 70°C for 4 h ; Then the solution was heated to 120°C, and the SO in the solution was evaporated 2 and HCl gas, after the solution was cooled to 80°C, 0.8 g of 4,4-bis(4-aminophenoxy)biphenyl was added to react for 18 h; then the solution was poured into ethanol and left to stand, then centrifugally washed with deionized water product, and then the product is placed in a rotary evaporator, and spin-dried at 80°C to obtain graphene oxide grafted 4,4-bis(4-aminophenoxy)biphenyl.

[0045] Prepare the solution accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com