Microencapsulated animal drug and preparation method thereof

A technology of microencapsulation and pharmaceuticals, which is applied in the direction of microcapsules, pharmaceutical formulations, non-active ingredients of polymer compounds, etc., and can solve the problems of irregular product particles, large energy consumption, easy oxidation and heat-sensitive materials that are not suitable , to achieve the effects of improving drug utilization, improving drug stability, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of microencapsulated animal medicine, comprising the following steps:

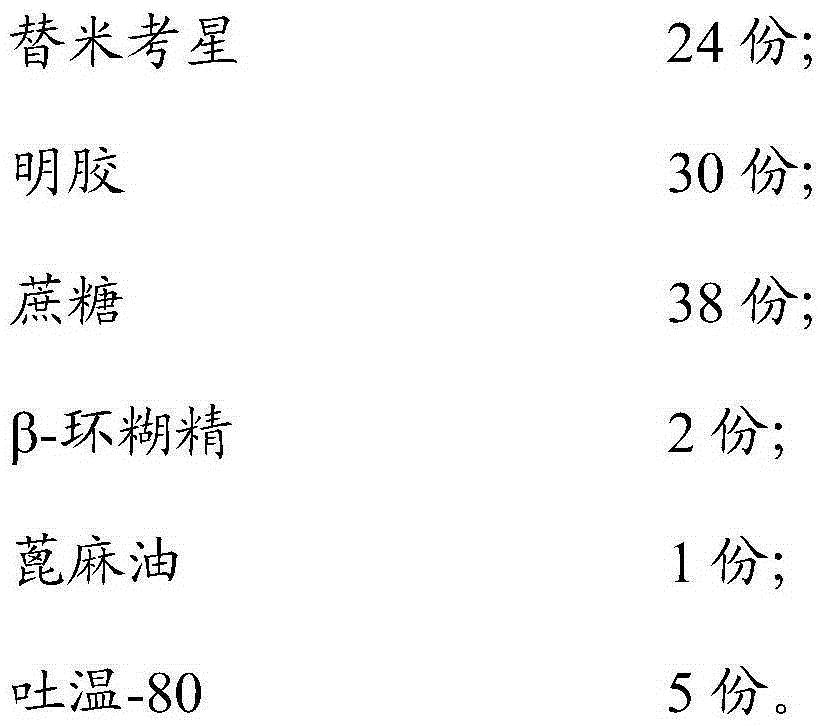

[0032] 1) Preparation of raw materials: weigh each component according to the following raw material formula, and set aside;

[0033]

[0034] 2) Preparation of the wall material: dissolve the wall material in 100 parts of water to obtain the water phase A;

[0035] 3) Preparation of capsule material: Dissolve tilmicosin in 300 parts of water, then add Tween-80 to obtain oil phase B;

[0036] 4) Preparation of dispersion system: under the condition that the shear power is 50KW and the stirring speed is 10000r / min, the oil phase B obtained in step 3) is added to the aqueous phase A obtained in step 2), and then the stirring time is 15min, at a temperature of 50°C, remove the solvent to form a microemulsion;

[0037] 5) Spray drying: add corn starch in the spray granulation tower, and the corn starch circulates, pump the microemulsion obtained in step 4) into the spray granul...

Embodiment 2

[0040] A preparation method of microencapsulated animal medicine, comprising the following steps:

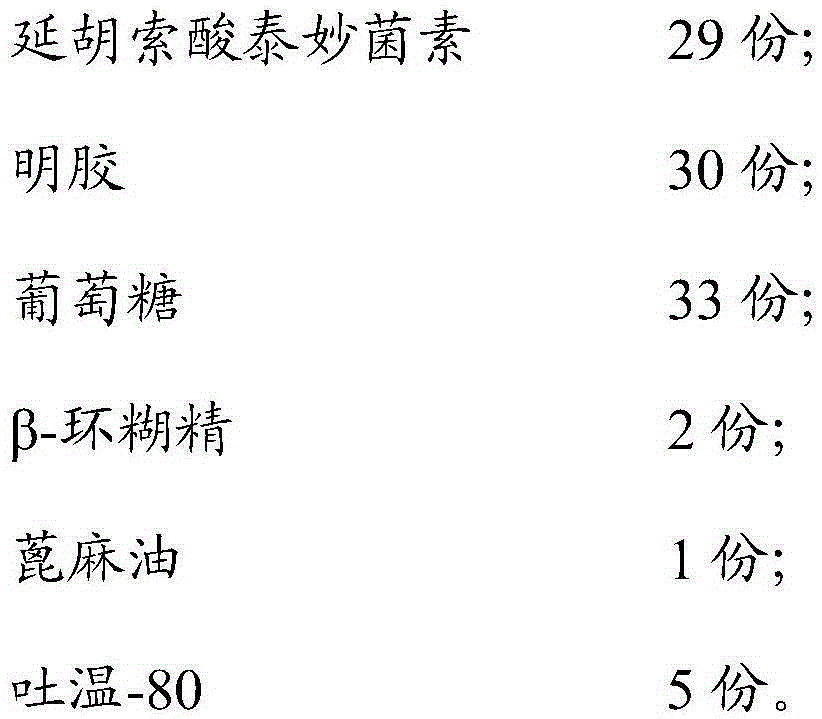

[0041] 1) Preparation of raw materials: weigh each component according to the following raw material formula, and set aside;

[0042]

[0043] 2) Preparation of the wall material: dissolve the wall material in 100 parts of water to obtain the water phase A;

[0044] 3) Preparation of capsule material: dissolve tiamulin fumarate in 360 parts of absolute ethanol, and then add Tween-80 to obtain oil phase B;

[0045] 4) Preparation of dispersion system: under the condition that the shear power is 80KW and the stirring speed is 12000r / min, the oil phase B obtained in step 3) is added to the aqueous phase A obtained in step 2), and then the stirring time is 15min, at a temperature of 50°C, remove the solvent to form a microemulsion;

[0046] 5) Spray drying: add corn starch in the spray granulation tower, and the corn starch circulates, pump the microemulsion obtained in step 4)...

Embodiment 3

[0049] A preparation method of microencapsulated animal medicine, comprising the following steps:

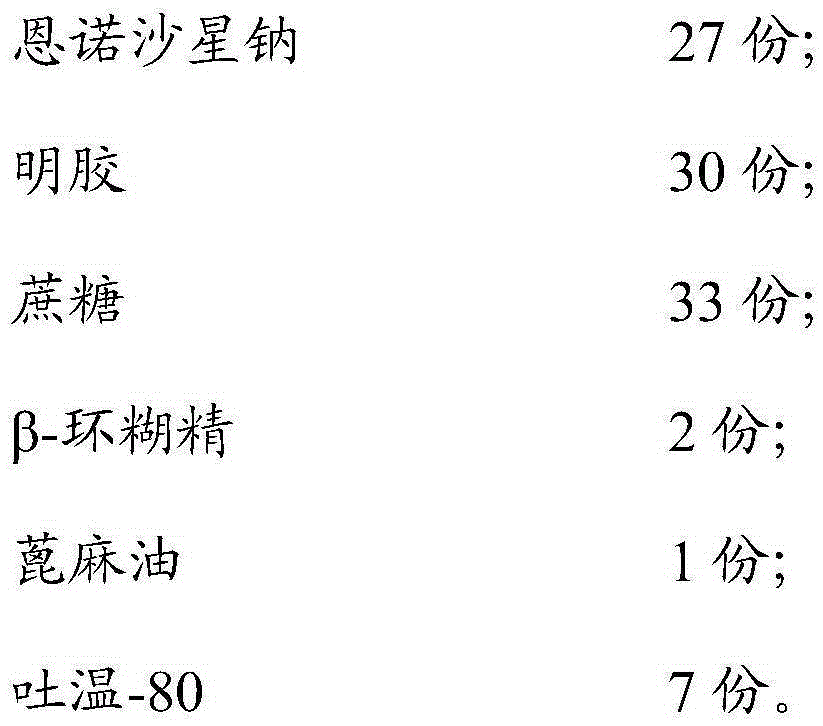

[0050]1) Preparation of raw materials: weigh each component according to the following raw material formula, and set aside;

[0051]

[0052] 2) Preparation of the wall material: dissolve the wall material in 100 parts of water to obtain the water phase A;

[0053] 3) Preparation of capsule material: dissolving enrofloxacin sodium in 360 parts of water, and then adding Tween-80 to obtain oil phase B;

[0054] 4) Preparation of dispersion system: under the condition that the shear power is 100KW and the stirring speed is 18000r / min, the oil phase B obtained in step 3) is added to the aqueous phase A obtained in step 2), and then the stirring time is 15min, at a temperature of 50°C, remove the solvent to form a microemulsion;

[0055] 5) Spray drying: add rice bran into the spray granulation tower, the rice bran circulates, pump the microemulsion obtained in step 4) into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com