High-tower granulation slow-release long-acting high-nitrogen sulfenyl compound fertilizer and preparation method thereof

A technology of high-tower granulation and compound fertilizer, which is applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of fertilizer efficiency decomposition loss block, low fertilizer utilization rate, no literature report, etc., and achieves beneficial environmental protection and nutrient distribution. Uniform and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

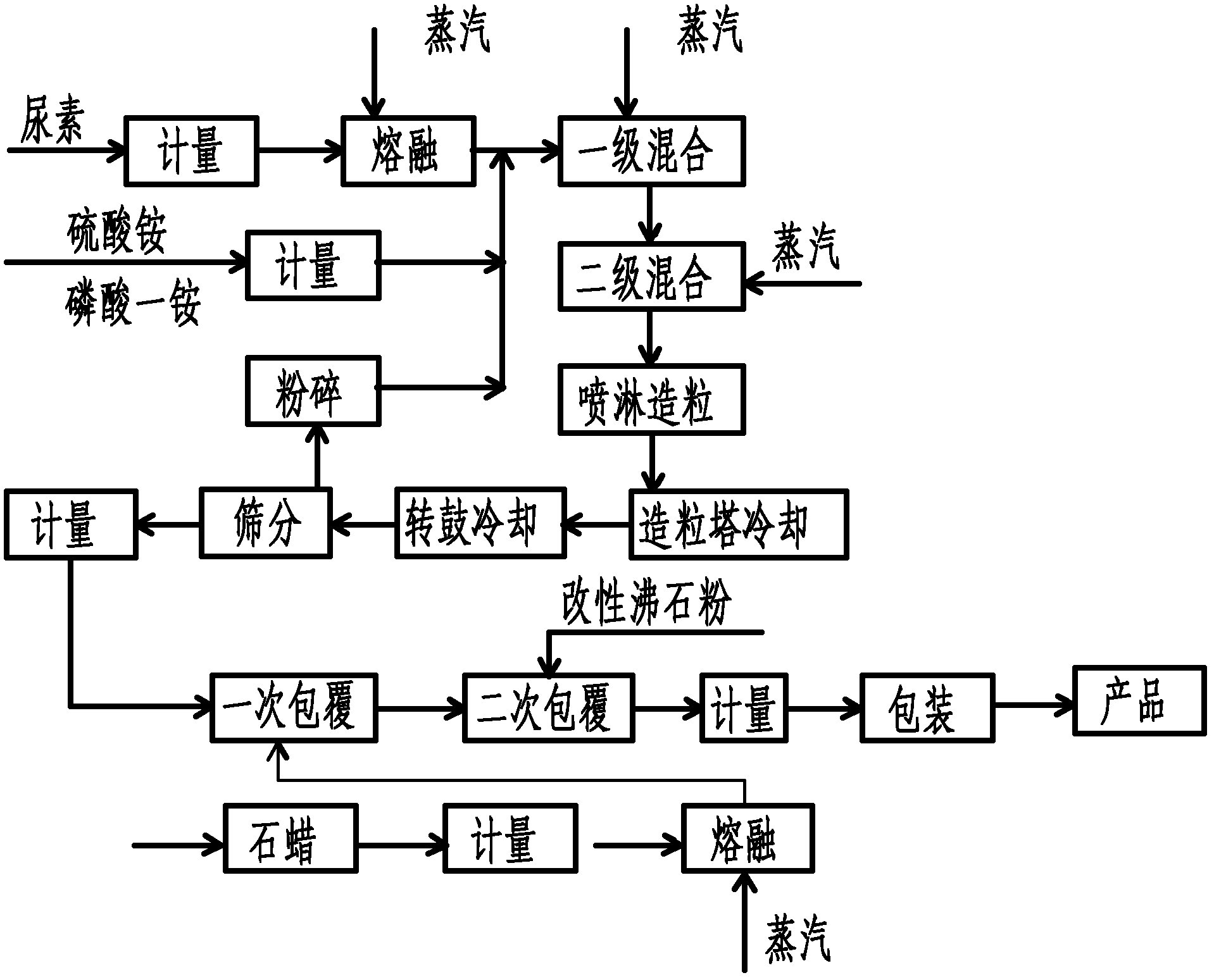

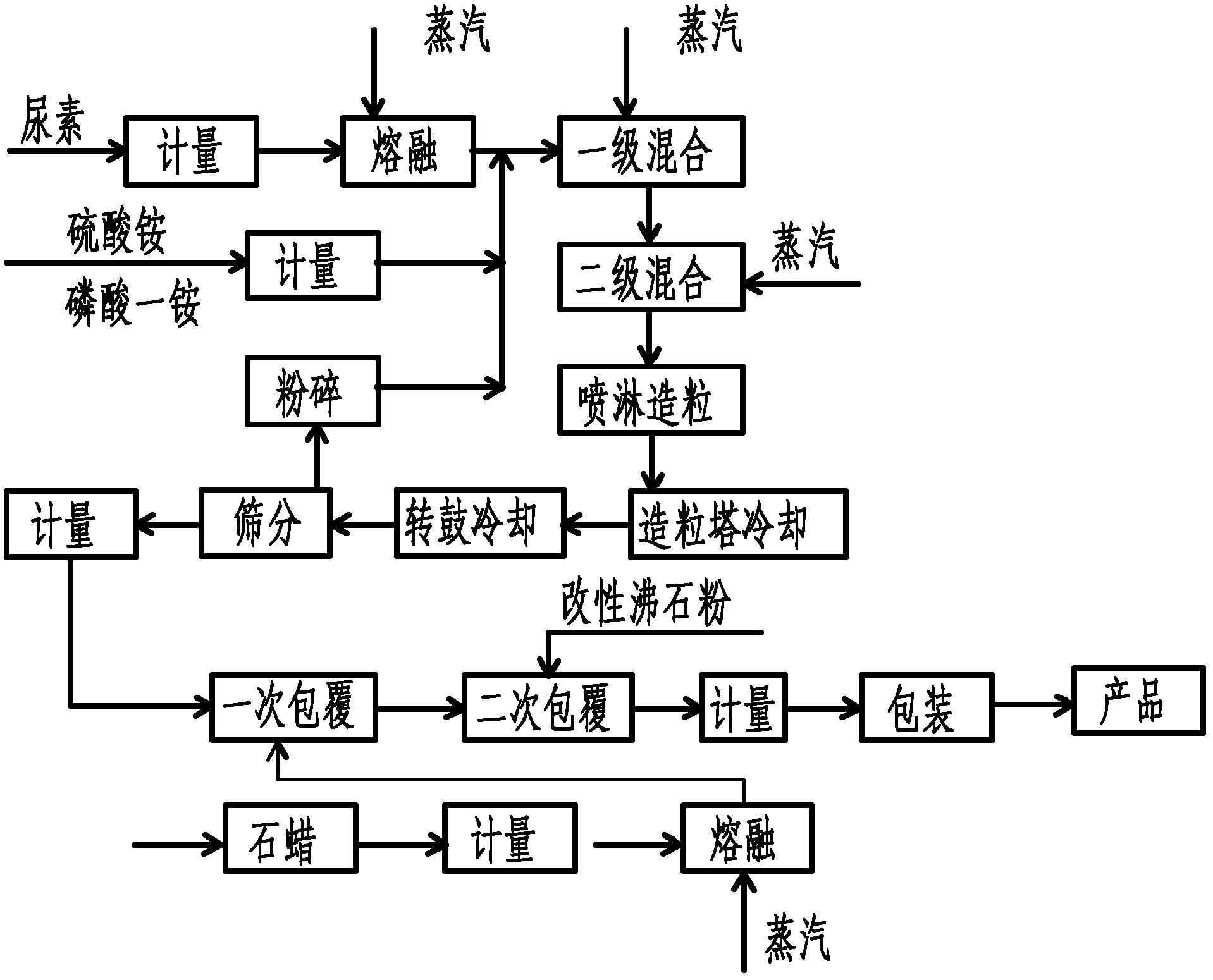

[0093] Prepare the high-tower granulation slow-release long-acting sulfur-based nitrogen-phosphorus compound fertilizer of the present invention according to the following steps

[0094] Step 1. Preparation of high-tower granulated compound fertilizer granules

[0095] a. Urea melting

[0096] Accurately weigh 35 parts by weight of urea, put it into a melting tank, heat to 133°C for melting, and prepare for primary mixing;

[0097] b. Monoammonium phosphate, ammonium sulfate preheating

[0098] Accurately weigh 38 parts by weight of monoammonium phosphate and 27 parts by weight of ammonium sulfate, put them into a primary mixing tank, preheat to 58°C, and set aside;

[0099] c. Co-melt preparation

[0100] Send the molten urea prepared in step a into the primary mixing tank, mix it with the preheated monoammonium phosphate and ammonium sulfate in step b, and then put it into the secondary mixing tank, and mix it evenly, and the slurry mixing time is less than 4min to form ...

Embodiment 2~ Embodiment 7

[0114] According to the method and steps of Example 1, according to the formula in Table 1, prepare the high-tower granulation slow-release long-acting sulfur-based nitrogen-phosphorus compound fertilizer of the present invention

[0115] Table 1

[0116] raw material Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 urea 33 35 37 34 40 43 Monoammonium Phosphate 26 30 26 27 28 38 ammonium sulfate 41 35 37 39 32 19 paraffin 0.5 0.6 0.8 0.7 0.9 1.0 Zinc stearate 1 2 3 4 2 5 Zeolite powder 99 98 97 96 98 95

[0117] The high-tower granulated slow-release long-acting sulfur-based nitrogen-phosphorus compound fertilizers prepared in Examples 1 to 7 are all applicable to the application of various field crops, vegetables and fruit trees, and can increase the fertilizer utilization rate by 10%-20% on average.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com