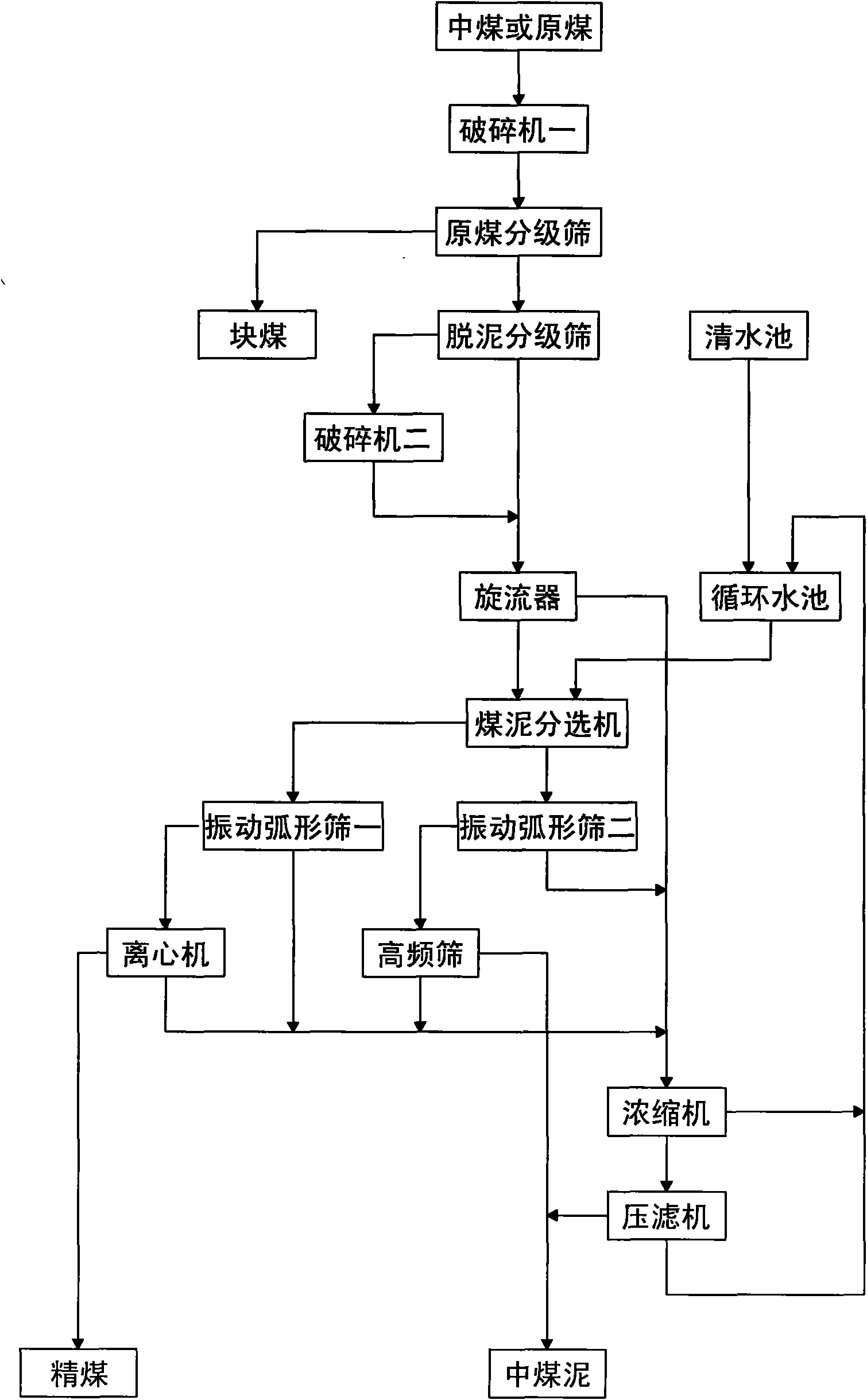

Process for selecting cleaned coals from gangue coals of raw coals and middling coals

A raw coal and process technology, applied in the process field of selecting clean coal, can solve the problems of high coal preparation cost, low efficiency, environmental pollution, etc., and achieve the effects of low coal preparation cost, simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] As shown in the figure, the raw coal or middling coal passes through the raw coal receiving pit in the raw coal freight yard, and then the vibrating feeder passes through the raw coal belt conveyor and enters the raw coal grading sieve with a screen hole of 50-80mm to sieve the lump coal to the ground. Crusher 1 is crushed and sent to the desliming grading sieve with a screen hole of 1-3 mm through the raw coal belt conveyor 2. The lump coal on the sieve of the desliming grading sieve enters the crusher 2. The overflow of the cyclone enters the thickener, the underflow enters the coal slime separator, the overflow of the separator enters the vibrating arc screen 1, the undersize enters the thickener, and the oversize enters the centrifuge, and the final clean coal is obtained after centrifugal dehydration The product and centrifugal liquid enter the concentrator, the underflow of the slime separator enters the vibrating arc screen 2, the undersize of the vibrating arc si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com