Mixed-coal blending combustion prediction system with post-evaluation system

A post-evaluation and coal blending technology, applied in forecasting, information technology support systems, instruments, etc., can solve problems such as inability to obtain enough design coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0164] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

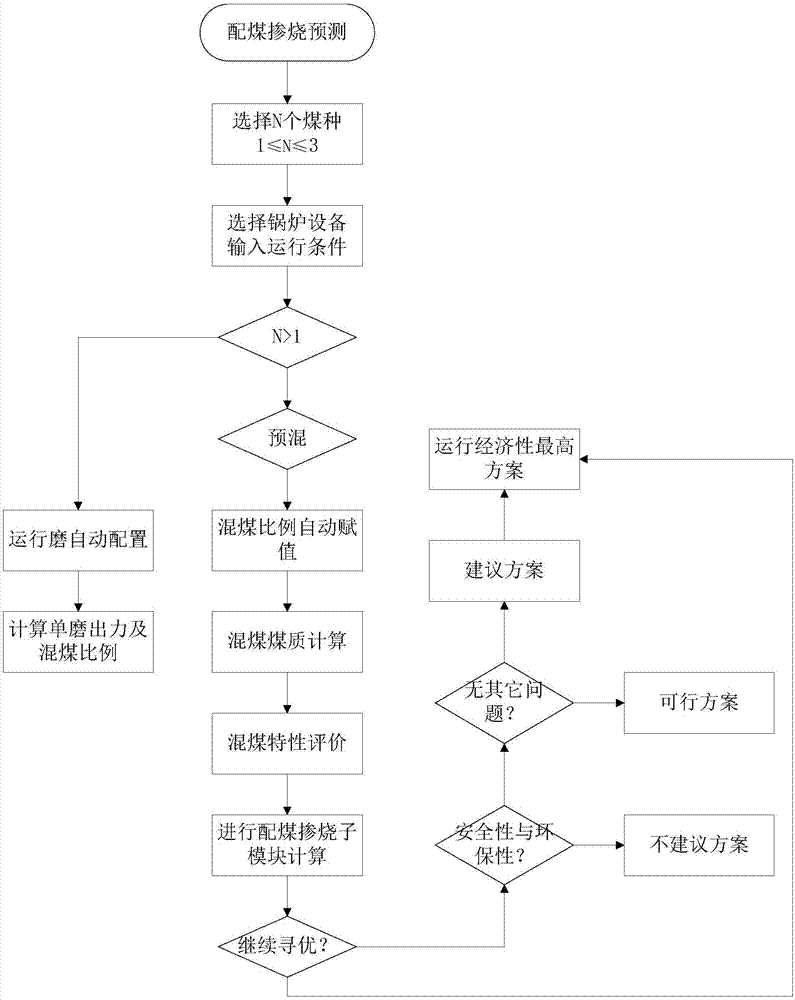

[0165] like figure 1 As shown, the coal blending and combustion prediction process:

[0166] 1. To start coal blending and blending prediction, first select 1-3 single coals from the China Power Coal Database and input coal quality data.

[0167] 2. Select the equipment information of the boiler for blending and input the operating conditions.

[0168] 3. Select the blending method as premixing or split grinding blending.

[0169] 4. Use the exhaustive method to automatically assign the coal blending ratio.

[0170] 5. Call the coal-fired coal quality calculation and coal quality evaluation sub-module to calculate and evaluate the mixed coal quality.

[0171] 6. Under the condition of the coal blending ratio, calculate the 2-8 modules of coal blending and blending prediction, and record the calculation results and evaluation conclusions.

[0172...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com