Magnetic separation belt

A technology for magnetically separating belts and belts, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient utilization of parts, unsatisfactory tail throwing rate, and undeveloped idler rollers, etc., to solve the problem of magnetic Wrapping and magnetic inclusions, ensuring long-term safe operation, and high efficiency in the magnetic separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

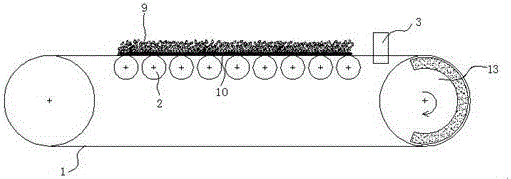

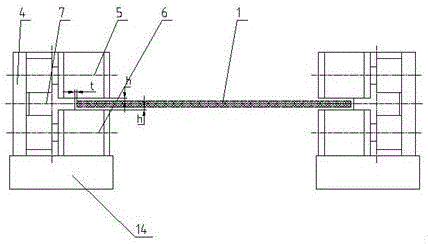

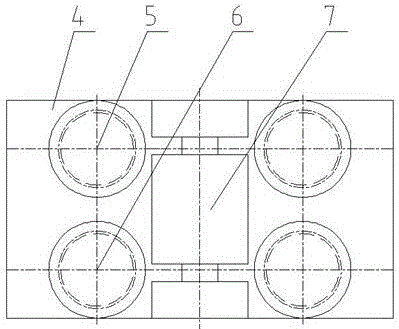

[0028] like figure 1 As shown, a magnetic separation belt, the inner side of the belt on the conveyor belt 1 is provided with a magnetic idler 2, and the two sides of the conveyor belt 1 are provided with a conveyor belt deviation correction wheel set 3, and the conveyor belt deviation correction wheel set 3 is installed on the elastic support 14. On the conveyor belt A magnetized wheel 13 is provided at the end of the belt in the moving direction, and the magnetic field range of the idler 2 covers the conveyor belt 1 adjacent to the idler 2 .

[0029] In the above structure, the conveyor belt deviation correcting wheels 3 arranged on both sides of the conveyor belt 1 can effectively prevent the deviation of the conveyor belt 1, eliminate the harm of "deviation", and ensure the normal operation of the conveyor belt 1. The idler 2 installed inside the conveyor belt 1, on the one hand, supports the belt and prevents the wear of the belt. On the other hand, because the idler 2 is...

Embodiment 2

[0037] This embodiment is the same as Embodiment 1, the difference is that the idler roller 2 is arranged on the inner side of the lower belt of the conveyor belt 1, such as Figure 5 As shown, when the material is sent to the magnetic field range of the roller 2, adjust the distance between the adjacent rollers 2, the strong magnetic material 12 is adsorbed by the roller on the lower surface of the conveyor belt 1 and falls into the concentrate mouth with the conveyor belt 1 running. , the weak magnetic material 11 is carried away by the conveying device 8 to realize the separation of the strong magnetic material 12 and the weak magnetic material 11. In order to make the roller 2 better achieve strong magnetic and weak magnetic sorting, the magnetic field strength of each roller 2 is different. In the direction of material transportation, the magnetic field strength of the roller 2 can be set alternately. , can also be gradient descent. When the magnetic material 10 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com