Coking raw material applicability classification, comprehensive quality evaluation and coal blending guiding method

A quality evaluation and applicability technology, applied in coke ovens, petroleum industry and other directions, can solve the problems of inability to guide the purchase of coking coal, a wide variety of coking coal, and selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

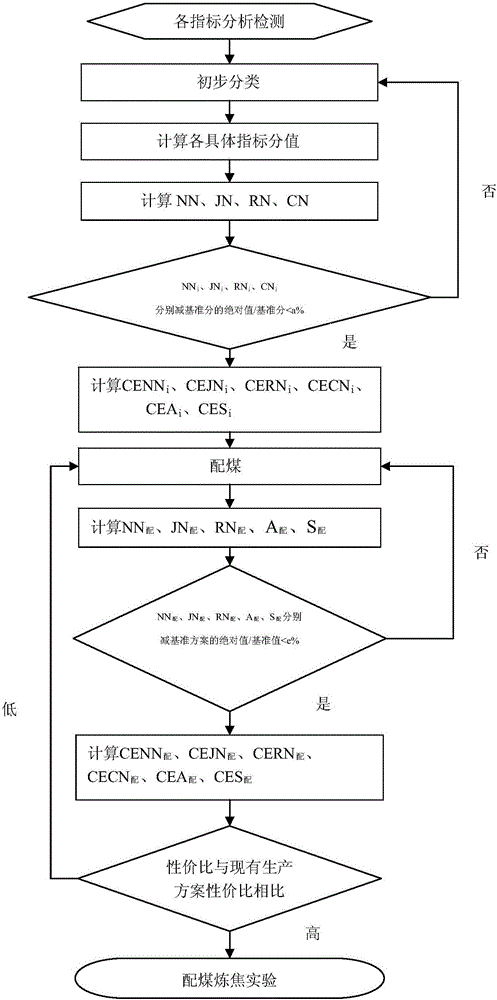

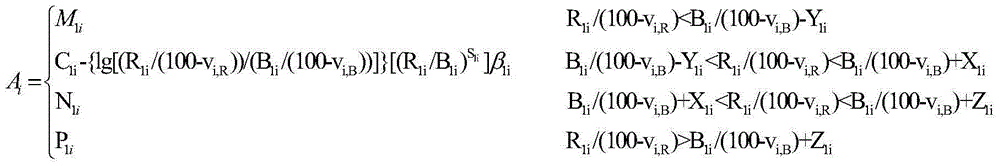

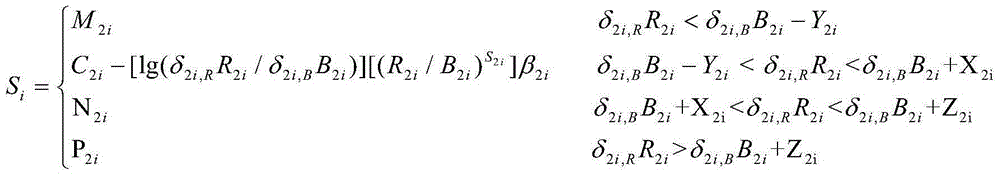

Method used

Image

Examples

specific Embodiment

[0185] The coking coal used by a coking enterprise for a long time is 3#~16# coal. 1# and 2# coal are newly introduced coking coals. According to the present invention, 1# to 16# coals are classified and comprehensively evaluated for quality, and the technical feasibility and role of 1# and 2# coals in coking coal blending are studied. The economy of coking coal is used to guide the coal procurement of coking enterprises. The results of coal quality analysis of 1#~16# coking coal and the quality analysis of coke obtained are shown in Table 1.

[0186] Table 1 Coal quality and coke quality indicators

[0187]

[0188] (1) Preliminary classification

[0189] According to the coal quality index and the Chinese coal classification standard "GB5751-2009", the coal is classified, and the blended coal is classified according to this standard. The preliminary classification results of 1# to 16# coking coal are as follows.

[0190] Table 2 Preliminary Classification

[0191] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com