Coal-rock blending method suitable for tamping coking

A technology for blending coal and coal and rock, applied in the field of coal-rock blending for tamping coking, can solve the problem that the influence of active components and inert components is not fully considered, the guiding role of vitrinite is not fully considered, and the tamping mixture is not considered. The problems of reasonable control of coal blending with low degree of metamorphism, etc., can achieve the effects of improving coke quality, expanding the use of coking coal resources, and refining the coal blending process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A coal-rock blending method suitable for tamping and coking, the method comprises the following steps:

[0040] The first step, according to national standards, for 12 kinds of single coals that meet the basic quality (coking coal 1 # - coking coal 12 # ), the ash content, volatile matter, total sulfur, cohesion index and colloidal layer index were tested, and the test results are shown in Table 1.

[0041] Table 1 Process properties of single coal

[0042]

[0043]

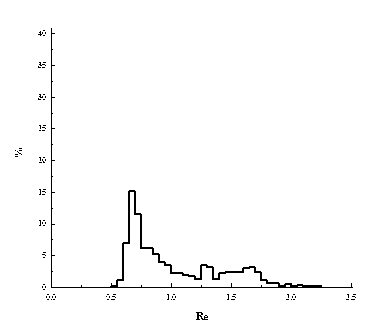

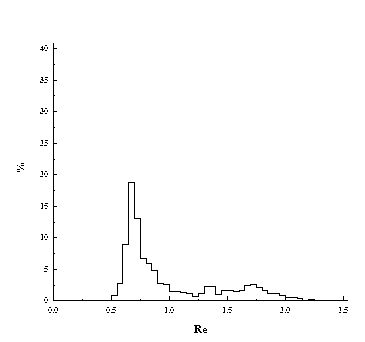

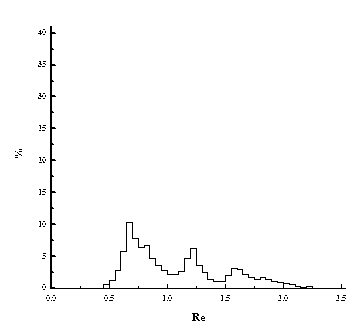

[0044] Then for the above 12 kinds of single coal (coking coal 1 # - coking coal 12 # ) of vitrinite random reflectance Re distribution ratio, vitrinite maximum average reflectance and coal rock microcomponents, and then calculate the active-inert ratio A / I of a single coal for coking according to the coal rock microcomponents. complex, so not listed) as shown in Table 2.

[0045] Table 2 Coal rock properties of single coal

[0046]

[0047] The second step: According to the activity-inert...

Embodiment 2

[0070] A coal-rock blending method suitable for tamping and coking, the method comprises the following steps:

[0071] The first step, according to national standards, for 12 kinds of single coals that meet the basic quality (coking coal 1 # ~ coking coal 12 # ) of ash, volatile matter, total sulfur, cohesion index and colloidal layer index for detection.

[0072] The single coal process property used in this embodiment is the same as the first step of embodiment 1, and the test results are as shown in Table 1 of embodiment 1.

[0073] Then for the above 12 kinds of single coal (coking coal 1 # ~ coking coal 12 # ) of vitrinite random reflectance Re distribution ratio, vitrinite maximum average reflectance and coal rock microcomponents are detected respectively, and then the active-inert ratio A / I of a single coal for coking is calculated according to the coal rock microcomponents. The detection and calculation results are shown in Table 2 of the first step of Example 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com