Radiation resistant composite knitted fabric and preparation thereof

A knitted fabric and anti-radiation technology, which is applied in knitting, weft knitting, warp knitting, etc., can solve the problems of not being able to meet the needs of daily wear and poor air permeability of knitted fabrics, and achieve the effect of ensuring cold protection, improving comfort and reducing friction degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

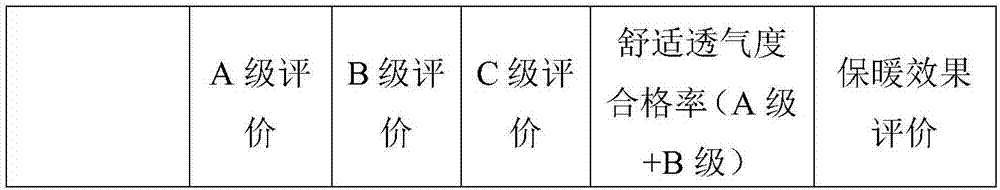

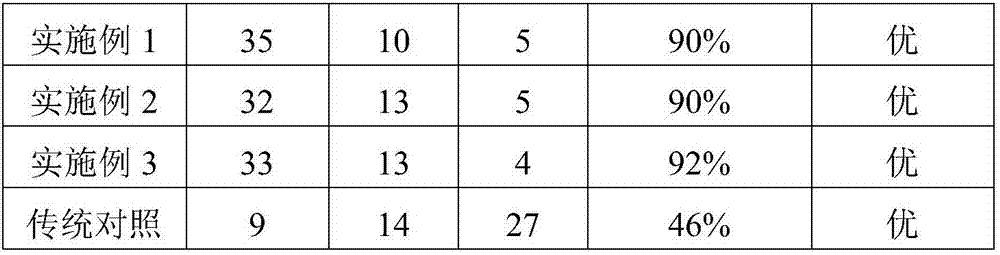

Embodiment 1

[0018] A radiation-resistant composite knitted fabric and its preparation. The composite knitted fabric is composed of an inner fabric layer and an outer fabric layer, and the inner fabric layer is composed of 40% wool blended fibers and 30% cotton fibers. , 5% new regenerated fiber and the balance of aramid fiber composite; the outer fabric layer includes 20% wool cashmere fiber, 16% metal fiber, 4% nano silver fiber, 25% extracted Anti-radiation plant fibers from plants with anti-radiation functions and the balance of aromatic polyamide fibers;

[0019] The inner fabric layer is woven by a weft knitting process composed of incomplete rib weave and plain stitch; the outer fabric layer is woven by a biaxial warp knitting process.

[0020] Wherein, the wool blended fiber is a blended fiber of wool, cashmere and mink, and the blending ratio of the three is 4:2:1; the new regenerated fiber is the quality of sea silk fiber, soft silk protein fiber and spider silk. The ratio is a ...

Embodiment 2

[0022] A radiation-resistant composite knitted fabric and its preparation. The composite knitted fabric is composed of an inner fabric layer and an outer fabric layer, and the inner fabric layer is composed of 60% wool blended fiber and 20% cotton fiber. , 10% new regenerated fiber and the balance of aramid fiber composite; the outer fabric layer includes 30% wool cashmere fiber, 5% metal fiber, 15% nano silver fiber, 15% extracted from Anti-radiation plant fibers of plants with anti-radiation function and the balance of aromatic polyamide fibers;

[0023] The inner fabric layer is woven by a weft knitting process composed of incomplete rib weave and plain stitch; the outer fabric layer is woven by a biaxial warp knitting process.

[0024] Wherein, the wool blended fiber is a blended fiber of wool, cashmere and mink, and the blending ratio of the three is 4:2:1; the new regenerated fiber is the quality of sea silk fiber, soft silk protein fiber and spider silk. The ratio is a...

Embodiment 3

[0026] A radiation-resistant composite knitted fabric and its preparation. The composite knitted fabric is composed of an inner fabric layer and an outer fabric layer, and the inner fabric layer is composed of 50% wool blended fibers and 25% cotton fibers. , 8% new regenerated fiber and the balance of aramid fiber composite; the outer fabric layer includes 25% wool cashmere fiber, 11% metal fiber, 9% nano-silver fiber, 20% extracted from Anti-radiation plant fibers of plants with anti-radiation function and the balance of aromatic polyamide fibers;

[0027] The inner fabric layer is woven by a weft knitting process composed of incomplete rib weave and plain stitch; the outer fabric layer is woven by a biaxial warp knitting process.

[0028] Wherein, the wool blended fiber is a blended fiber of wool, cashmere and mink, and the blending ratio of the three is 4:2:1; the new regenerated fiber is the quality of sea silk fiber, soft silk protein fiber and spider silk. The ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com