Preparation method of modified polyvinyl chloride

A polyvinyl chloride, modified technology, applied in the field of polymers, can solve the problems of non-sterilization, destruction of the atmospheric ozone layer, and incomplete sterilization of ethylene oxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

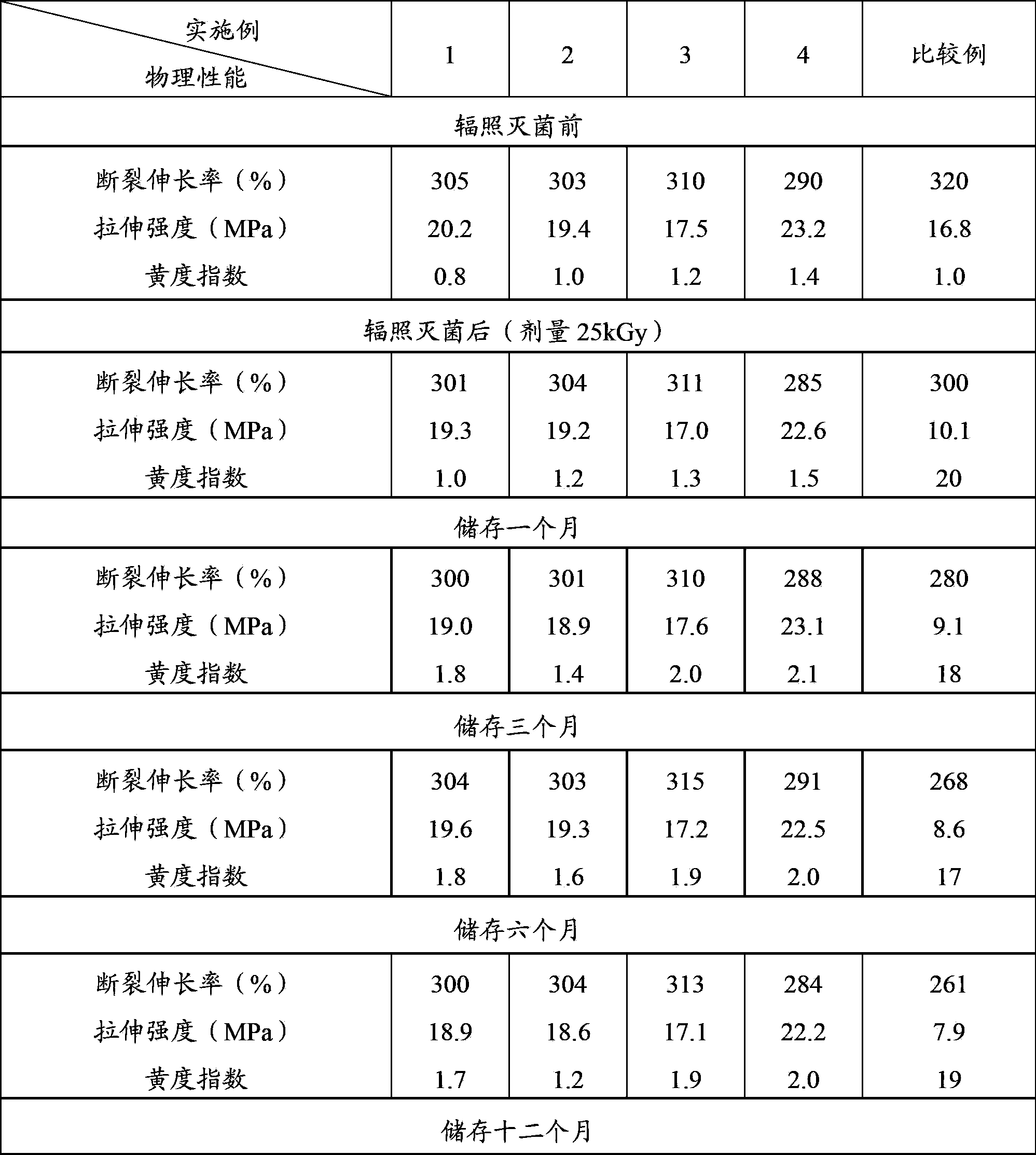

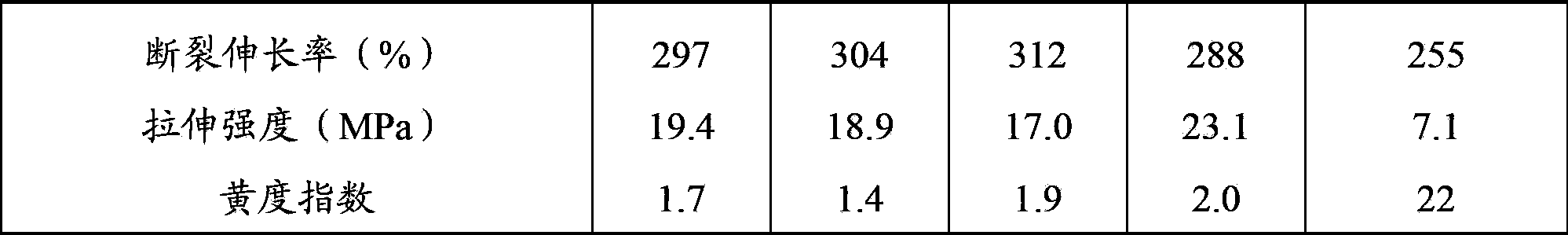

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of modified polyvinyl chloride, comprises the following steps:

[0025] a) Mix polyvinyl chloride, unsaturated reactive hindered amine and initiator, and after grafting reaction, obtain hindered amine graft-modified polyvinyl chloride;

[0026] b) After mixing polyvinyl chloride, plasticizer, epoxy ester compound, calcium zinc stabilizer and metal soap compound, melt extruding to obtain a polyvinyl chloride composition;

[0027] c) melt extruding the hindered amine graft modified polyvinyl chloride obtained in step a) and the polyvinyl chloride composition obtained in step b) to obtain modified polyvinyl chloride;

[0028] The steps a) and b) are not limited in time order.

[0029] The method provided by the invention uses unsaturated reactive hindered amines to graft and modify polyvinyl chloride. Uniform dispersion on vinyl chloride can guarantee the anti-radiation performance of polyvinyl chloride for a long time....

Embodiment 1

[0053] Add 19.9g of acryloyl chloride into a three-necked flask containing 100mL of dry toluene, and cool the resulting solution in an ice bath, then slowly add 31.2g of 4-amino-2,2,6,6-tetra Methyl piperidine, the time of dropping is 30min, after reacting the obtained mixed solution for 2h under the condition of stirring, a white precipitate is obtained; the obtained white precipitate is filtered, and the molar concentration is 0.2mol / L sodium hydroxide The solution was washed and then recrystallized from pentanol to give 4-acrylamido-2,2,6,6-tetramethylpiperidine.

Embodiment 2

[0055] 1000 grams of polyvinyl chloride, 10 grams of 4-acrylamido-2,2,6,6-tetramethylpiperidine prepared in Example 1 and 5 grams of 2,5-dimethyl-2,5-di-tert The butyl peroxide hexane initiator is mixed in a high stirrer, and then the mixture obtained is added to a twin-screw extruder to carry out melt grafting reaction extrusion, and the reaction extrusion temperature is 160 ° C, and the screw speed is 150 rpm. The reaction time is 1.8 minutes, and the hindered amine 4-acrylamido-2,2,6,6-tetramethylpiperidine graft-modified polyvinyl chloride A is obtained;

[0056] 1000 grams of polyvinyl chloride, 500 grams of bis(2-ethylhexyl) phthalate, 30 grams of epoxy soybean oil, 20 grams of calcium zinc stabilizer, 3 grams of calcium stearate and 3 grams of zinc stearate After hot mixing and cold mixing in a high mixer, the obtained mixture is put into a twin-screw extruder for melt reaction extrusion. The extrusion temperature is 165°C, the screw speed is 130rpm, and the residence t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com