A kind of nano-toughened inorganic zinc-rich coating and preparation method thereof

An inorganic zinc-rich coating and toughening technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as easy cracking, poor coating flexibility, limited use, etc., to reduce porosity, overcome poor toughness, and improve anti- Effects of Corrosive Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also includes a preparation method of nano-toughened inorganic zinc-rich coating, comprising:

[0032] S101. Preparation of raw materials: prepare the raw materials in component A, component B and component C respectively;

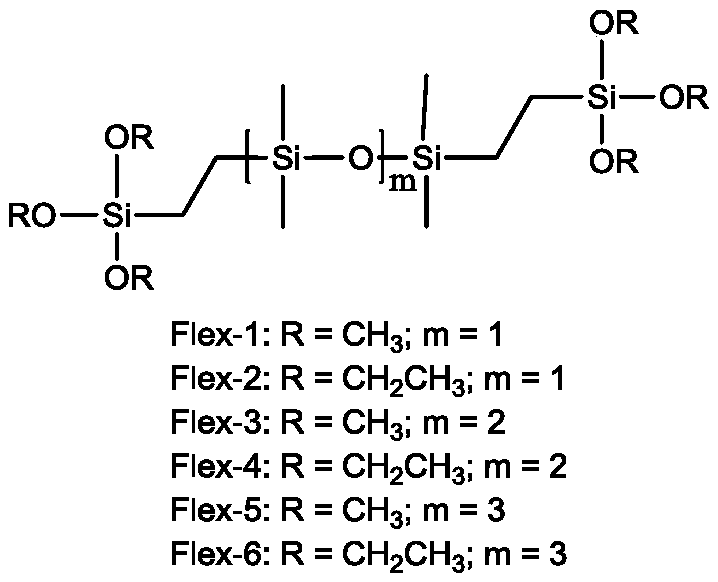

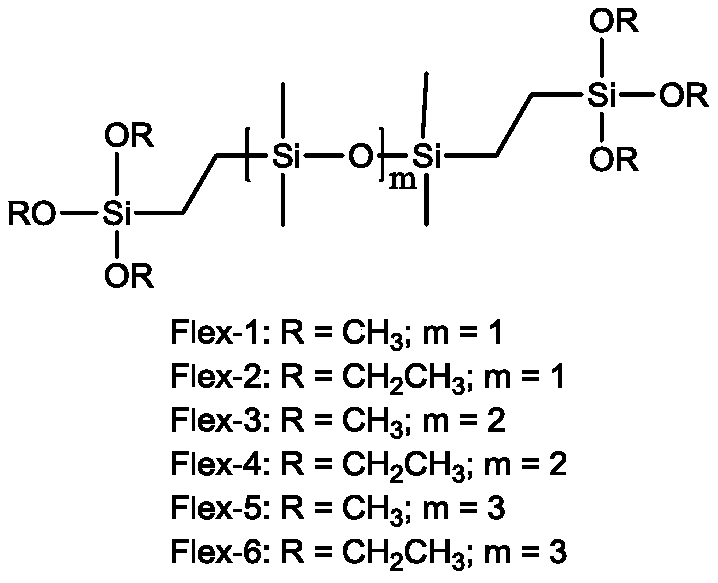

[0033] S102. Preparation of component A: According to the proportion in component A, add ethanol, isopropanol, propylene glycol methyl ether and cellulose thickener into the container, stir until it becomes a transparent liquid, add filler, and stir for 10-20 minutes Finally, grind at a high speed in a grinder, disperse to a fineness of ≤80 μm, then add tetraethyl orthosilicate prepolymer and flexible silicone nano-toughening particles, continue stirring for 30 minutes, and filter the material to obtain component A;

[0034] S103. Preparation of component C: According to the proportion in component C, add isopropanol and propylene glycol methyl ether into the container, gradually add polyvinyl butyral toughening resin under sti...

Embodiment 1

[0038] Preparation of nano-toughened inorganic zinc-rich coating T-1

[0039] 1) Component A raw material preparation and preparation

[0040]Prepare the raw materials required for component A, wherein the flexible organosilicon nano-toughening particles are formed by the hydrolysis and condensation of the organosilicon toughening precursor Flex-1; the specific synthesis method is: first add 300g of ethanol or isopropanol to the reaction vessel , 60g of acetic acid aqueous solution with a pH value of 4 to 5, then add 300g of silicone toughening precursor Flex-1, stir at room temperature for 0.5h, and stir at 70°C for 3h to obtain flexible silicone nano toughened particles solution, the average particle diameter of flexible organosilicon nano-toughening particles is 5nm;

[0041] Table 1.1, Raw material ratio in component A

[0042]

[0043] According to the ratio of component A in the above table 1.1, add ethanol, isopropanol, propylene glycol methyl ether and cellulose t...

Embodiment 2

[0053] Preparation of nano-toughened inorganic zinc-rich coating T-2

[0054] 1) Component A raw material preparation and preparation

[0055] Prepare the raw materials required for component A, wherein the flexible organosilicon nano-toughening particles are formed by the hydrolysis and condensation of the organosilicon toughening precursor Flex-1; the specific synthesis method is: first add 200g of ethanol or isopropanol to the reaction vessel , 37.5g of sulfuric acid aqueous solution with a pH value of 4 to 5, then add 300g of silicone toughening precursor Flex-2, stir at room temperature for 0.5h, then stir and react at 70°C for 1h to obtain flexible silicone nano-toughened Particle solution, the average particle size of flexible silicone nano-toughened particles is 10nm;

[0056] Table 2.1, Raw material ratio in component A

[0057]

[0058] According to the ratio of component A in the above table 2.1, add ethanol, isopropanol, propylene glycol methyl ether, and cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com