Method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes

A technology for coal gangue and alumina, which is applied in the field of coal gangue combustion ash and slag to extract alumina, silica and iron oxide, can solve the problems of energy utilization that the production of silica and iron oxide has not been reported in the literature, etc., and achieves remarkable energy saving effect. , the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

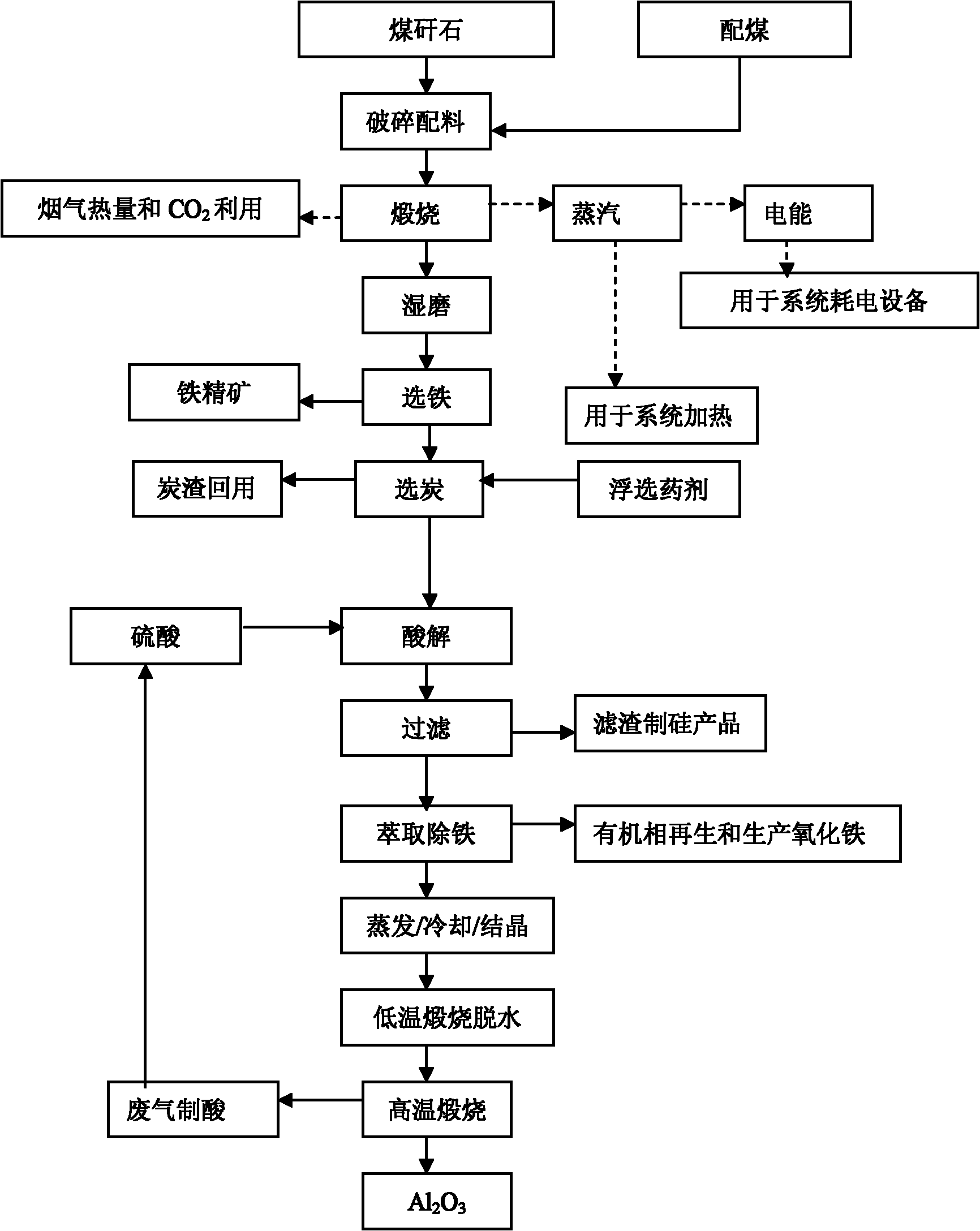

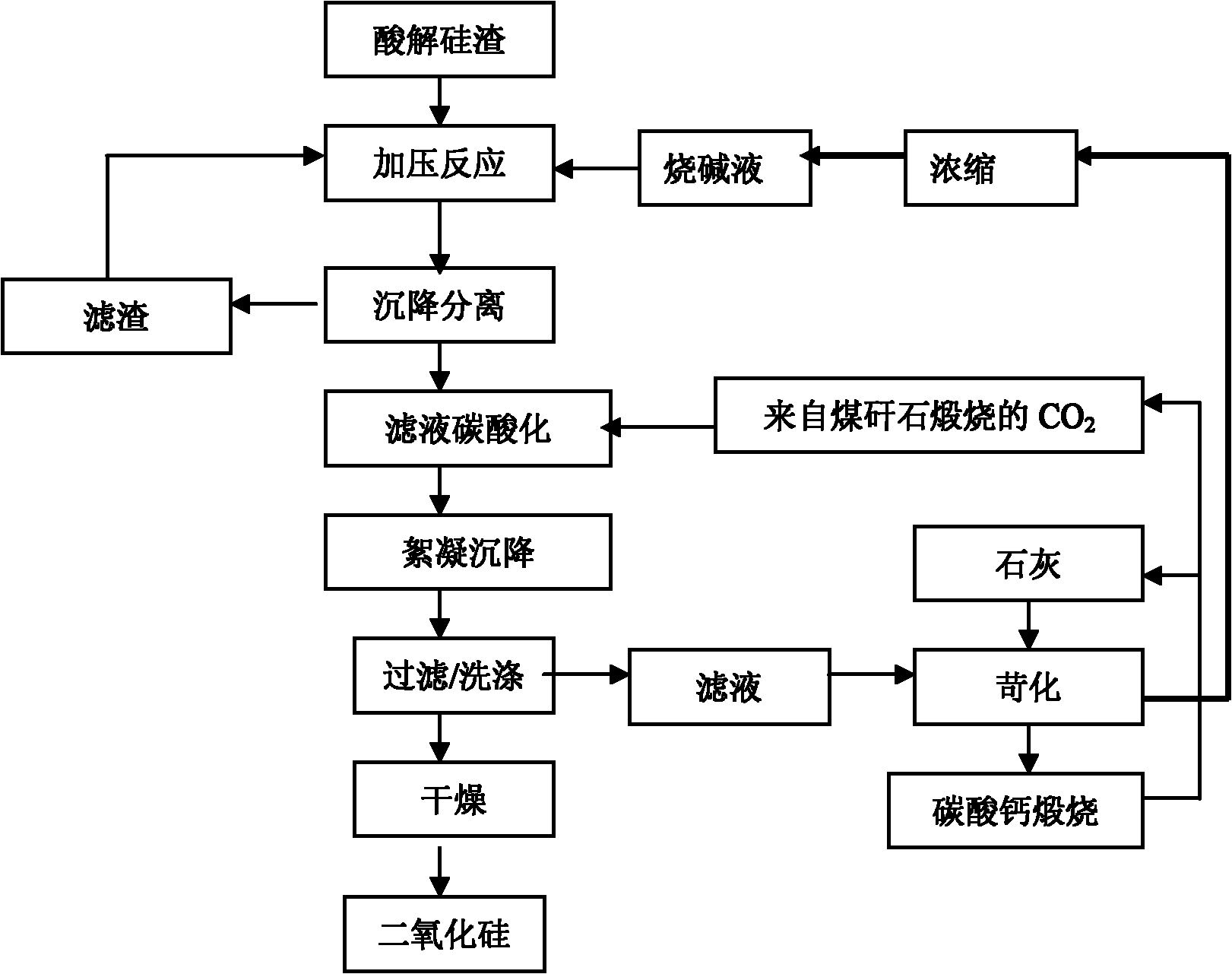

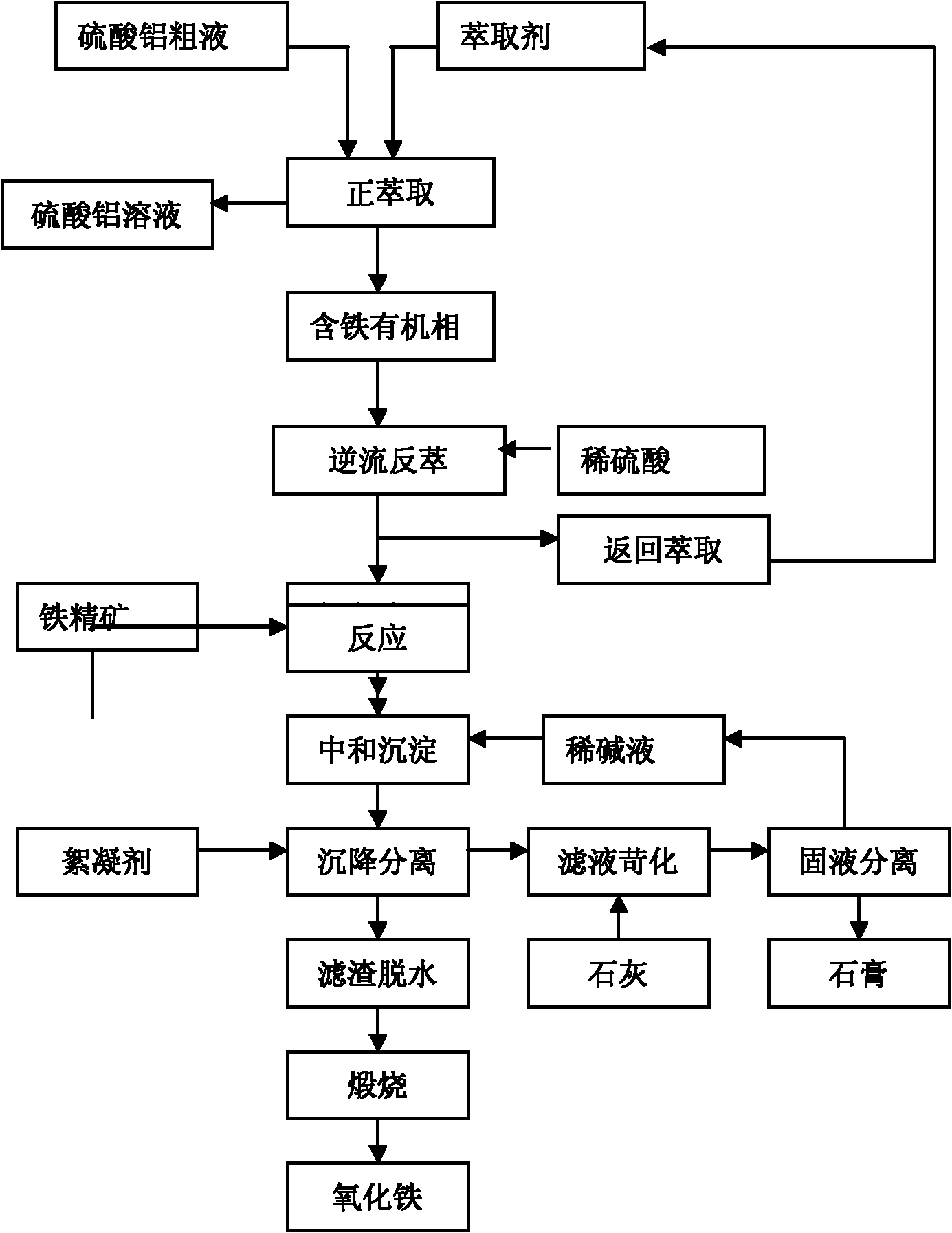

[0042] Such as Figure 1-3 As shown, a method for extracting alumina, silicon oxide and iron oxide from coal gangue combustion ash described in the embodiment of the present invention, the coal gangue is pretreated and blended with coal according to the calorific value, and the coal gangue is calcined to generate electricity at the same time. Activated, the generated electricity and steam are used by the system; the ash residue is extracted by acid method to extract alumina, alkali method to extract silicon oxide, and iron oxide is extracted by comprehensive utilization of by-products; acid, alkali, lime, Extractant and CO 2 cycle through the system. The method for using coal gangue to generate electricity includes the following steps: firstly, the coal gangue is crushed into particles with a maximum size smaller than 20mm; then the coal gangue and coal powder are mixed according to a mass ratio of 1:0.05-0.8, burned in a furnace, and burned The temperature is 600-1000°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com