Patents

Literature

70results about How to "Achieving the goal of reducing staff and increasing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

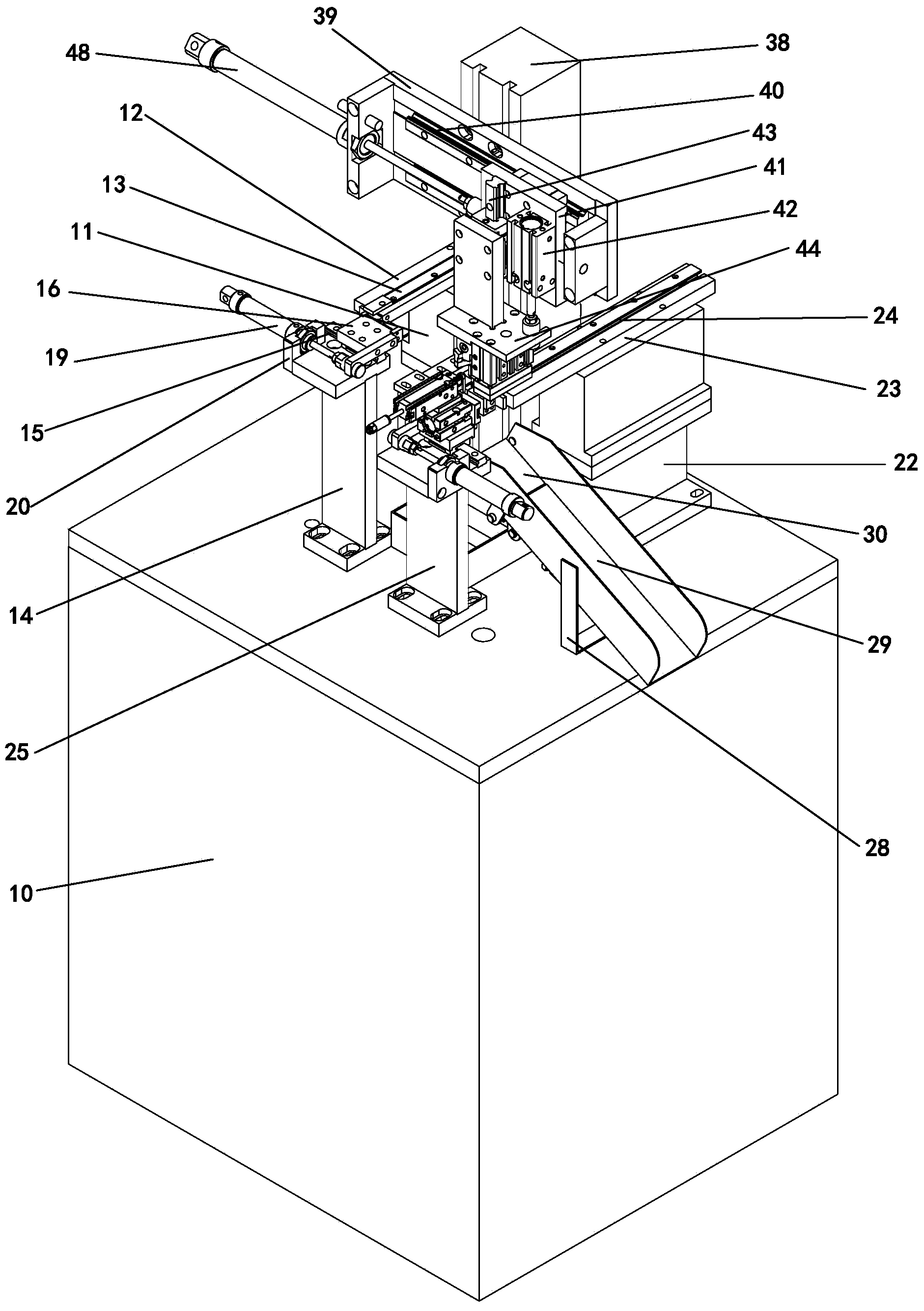

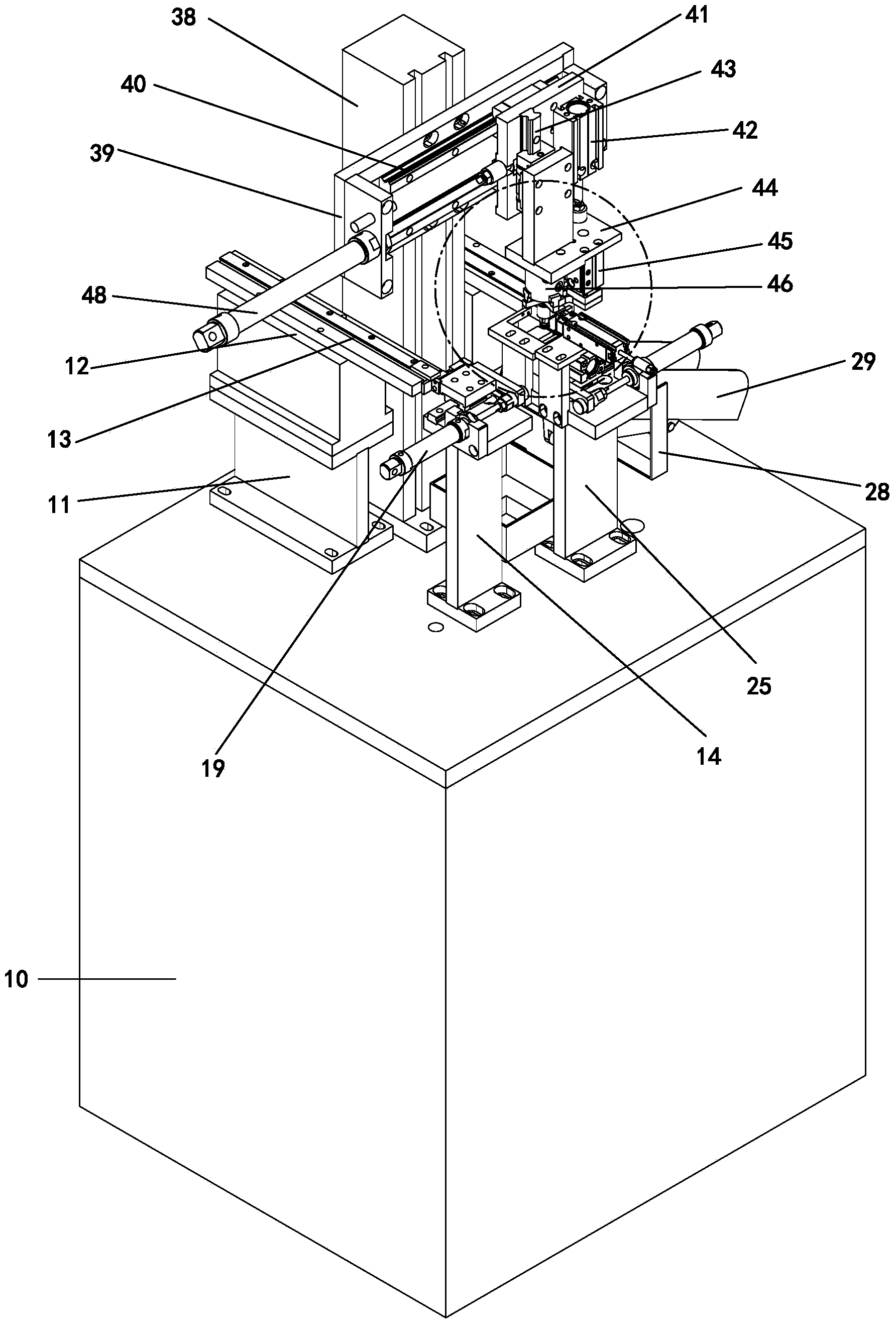

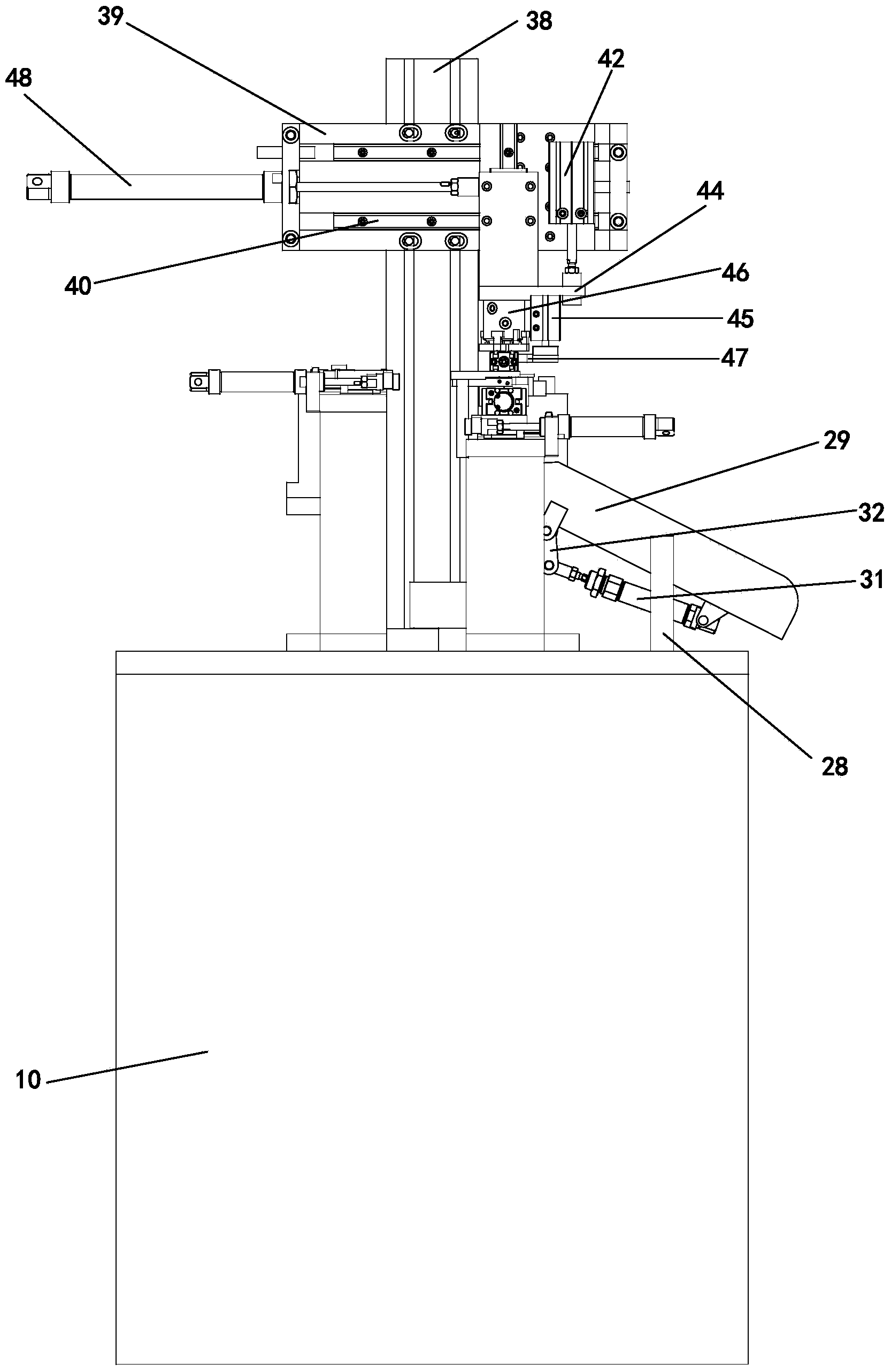

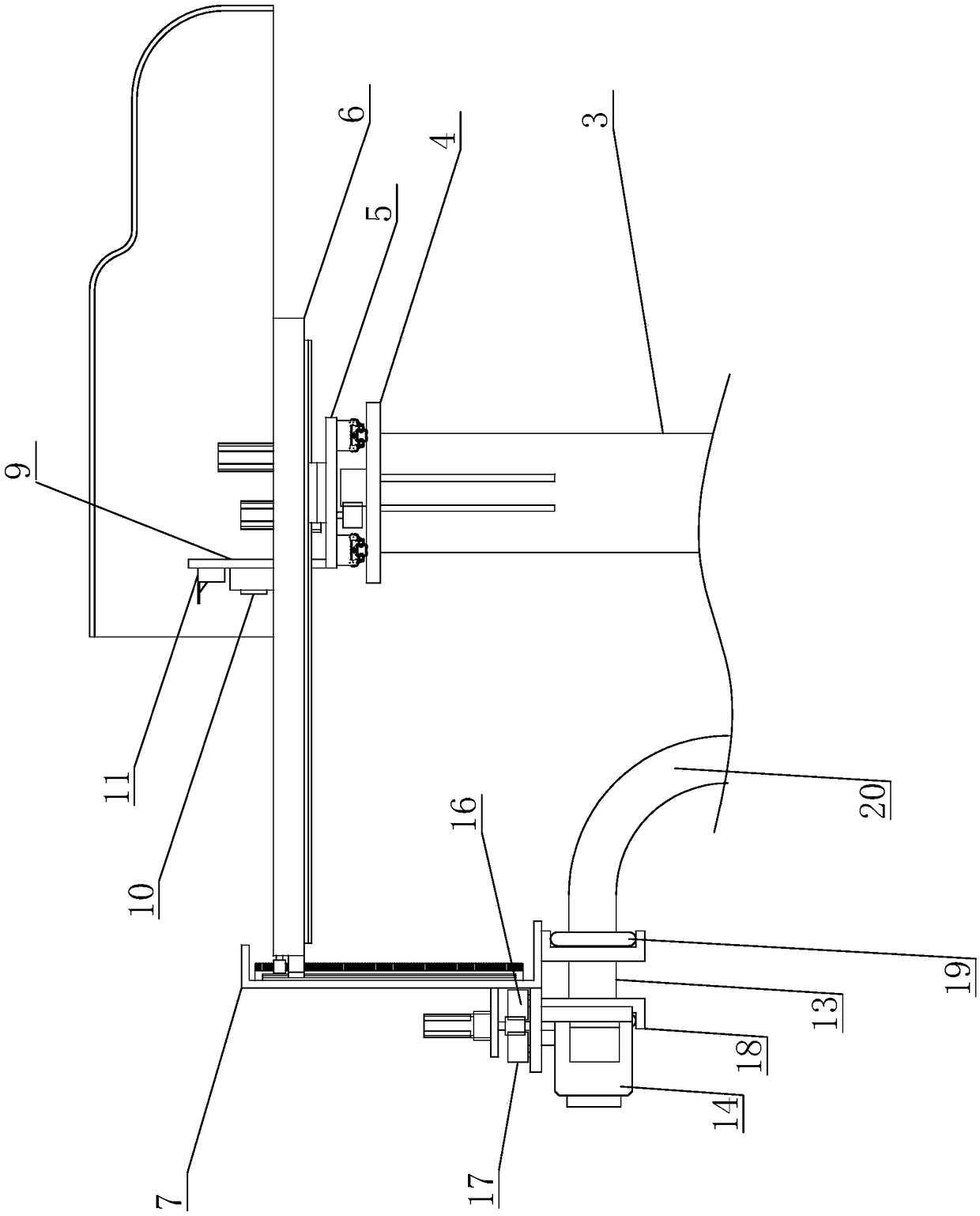

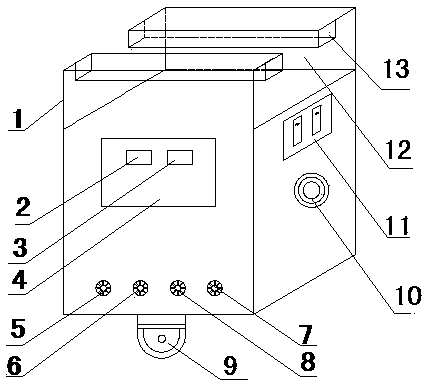

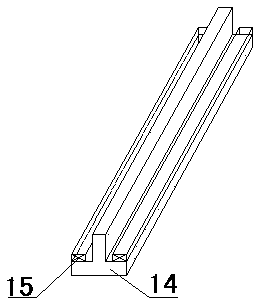

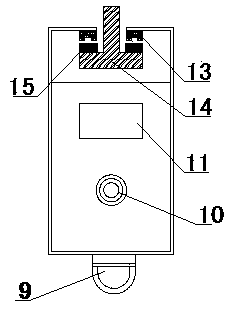

Device for assembling O-shaped ring on valve stem

ActiveCN103909495AThe machine is easy to operateSmall sizeMetal working apparatusMetal-working hand toolsValve stemEngineering

The invention relates to the technical field of valve stem assembling equipment, in particular to a device for assembling O-shaped rings on valve stems. The device comprises a frame, an O-shaped ring feeding mechanism, an O-shaped ring positioning mechanism, a valve stem feeding mechanism, a valve stem positioning mechanism, an O-shaped ring conveying and assembling mechanism and a finished product discharging and distributing mechanism are fixed on the frame, the O-shaped ring positioning mechanism is arranged on one side of the O-shaped ring feeding mechanism, the O-shaped ring conveying and assembling mechanism is arranged on the other side of the O-shaped ring feeding mechanism and capable of conveying an O-shaped ring in the O-shaped ring positioning mechanism to the position of the valve stem positioning mechanism and assembling the O-shaped ring in a valve stem of the valve stem positioning mechanism, the valve stem positioning mechanism is disposed on one side of the valve stem feeding mechanism, and the finished product discharging and distributing mechanism is arranged on the lower side of the valve stem positioning mechanism. The device for assembling the O-shaped rings on the valve stems has the advantages that assembling efficiency is high, demanded manpower is saved greatly, assembling time is saved, and product quality is guaranteed greatly.

Owner:ZHEJIANG VALOGIN TECH

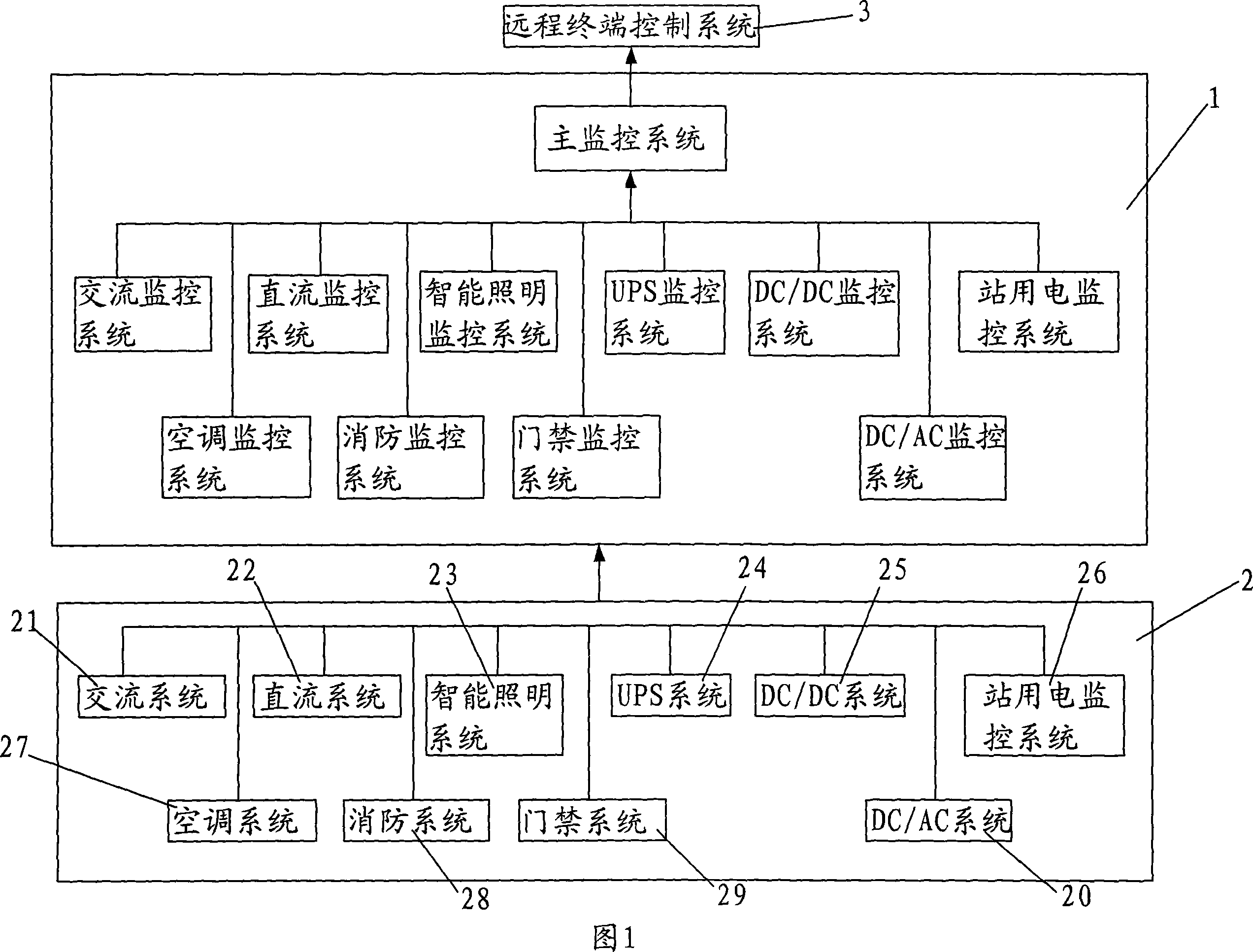

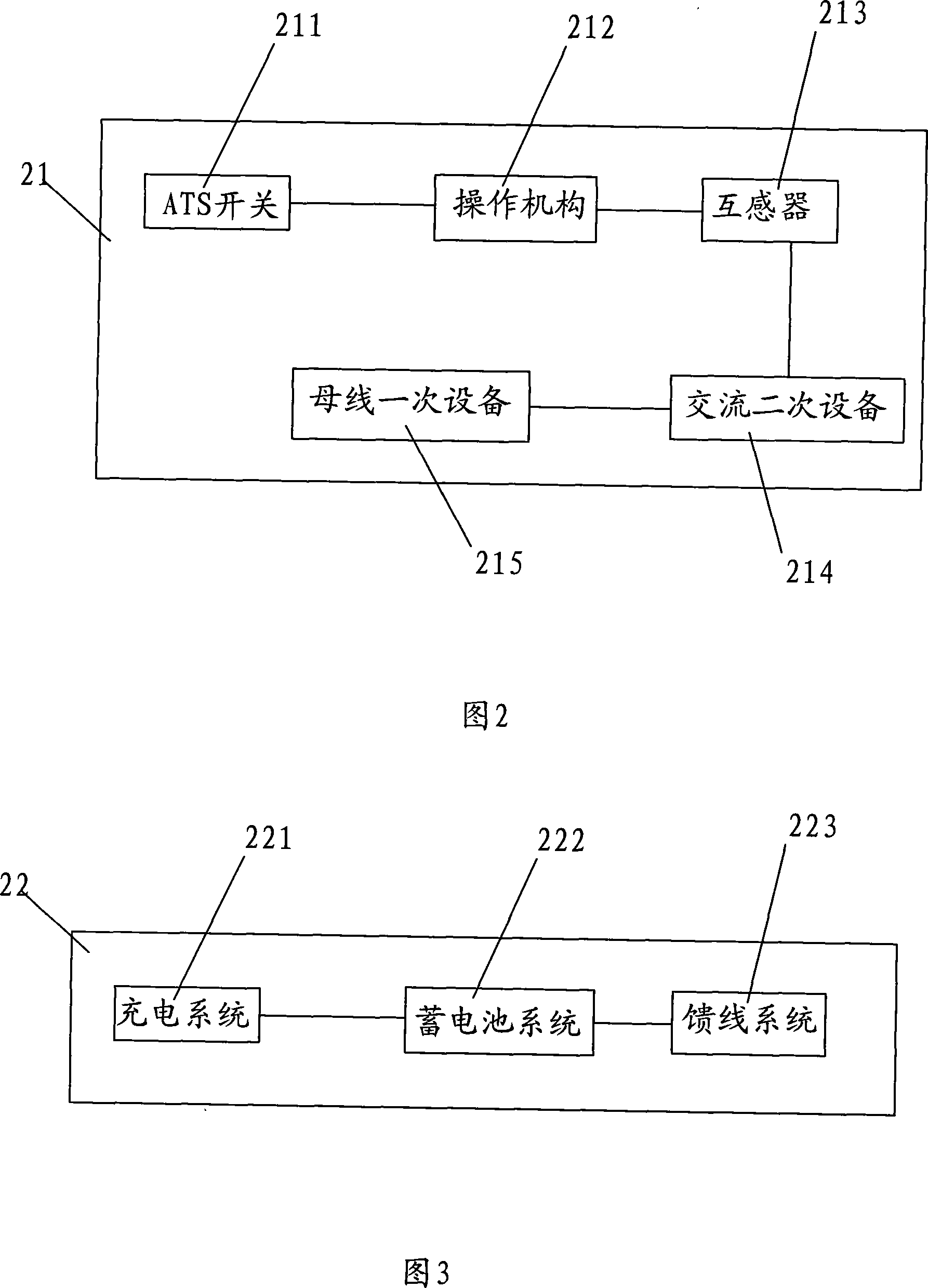

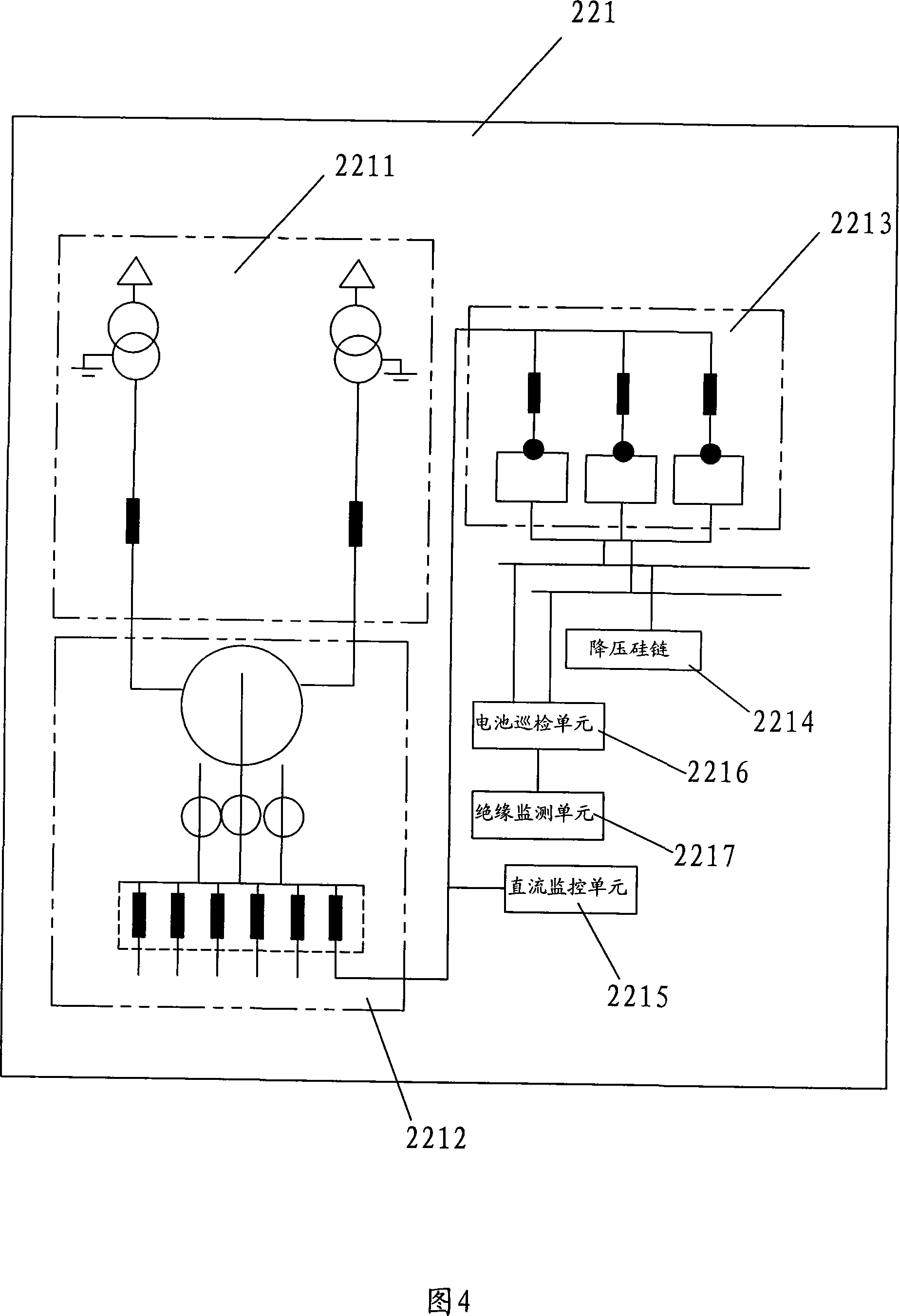

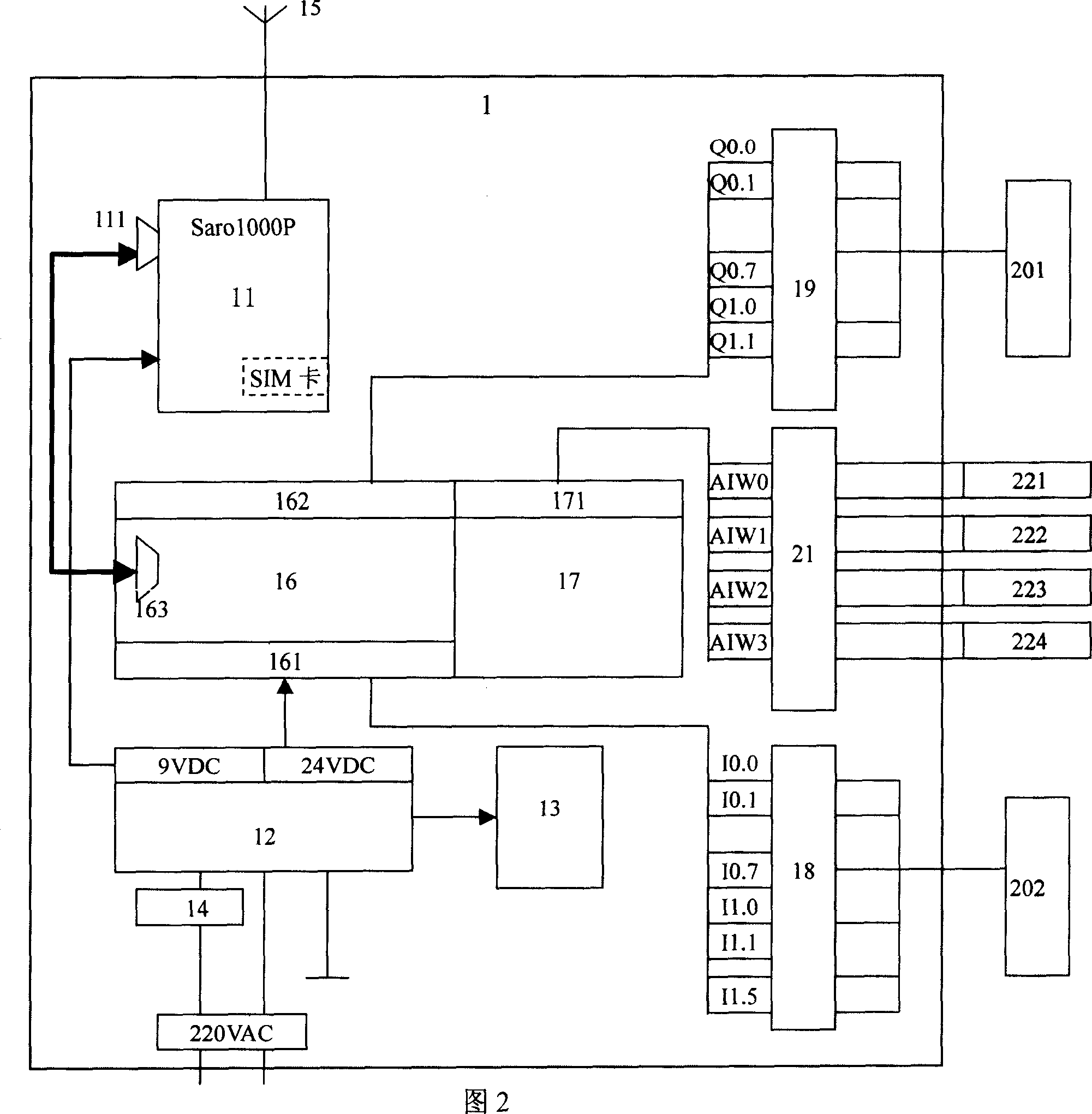

Intelligent management system for transformer substation assisted devices

InactiveCN101127456AReduce workloadImprove work efficiencyComputer controlCircuit arrangementsControl systemMonitoring system

The utility model discloses an intelligent management system for the auxiliary equipment of transformer substations, which comprises a monitoring platform; wherein, the monitoring platform is directly connected with the subsystem of the auxiliary equipment, and sends four-remote signals to the remote terminal control system or the dispatching center through network communications. The monitoring platform is designed into an industrial computer, which can acquire the analog quantity and the digital quantity information from the subsystem of the auxiliary equipment, and control and adjust AC / DC devices as well as other auxiliary devices. a monitoring system corresponding to the subsystem of the auxiliary equipment and a switching value I / O unit are arranged on the monitoring platform. By means of the system, the equipment maintenance staff can monitor the running status of nearly all equipment in the substation, particularly in the event of abnormal operations, can timely receive the alarm signal, and deal with the problems promptly. In short, the operation of the system reduces the workload, enhances the working efficiency, downsizes staffs and improves efficiency.

Owner:安徽泰昂电力技术有限公司

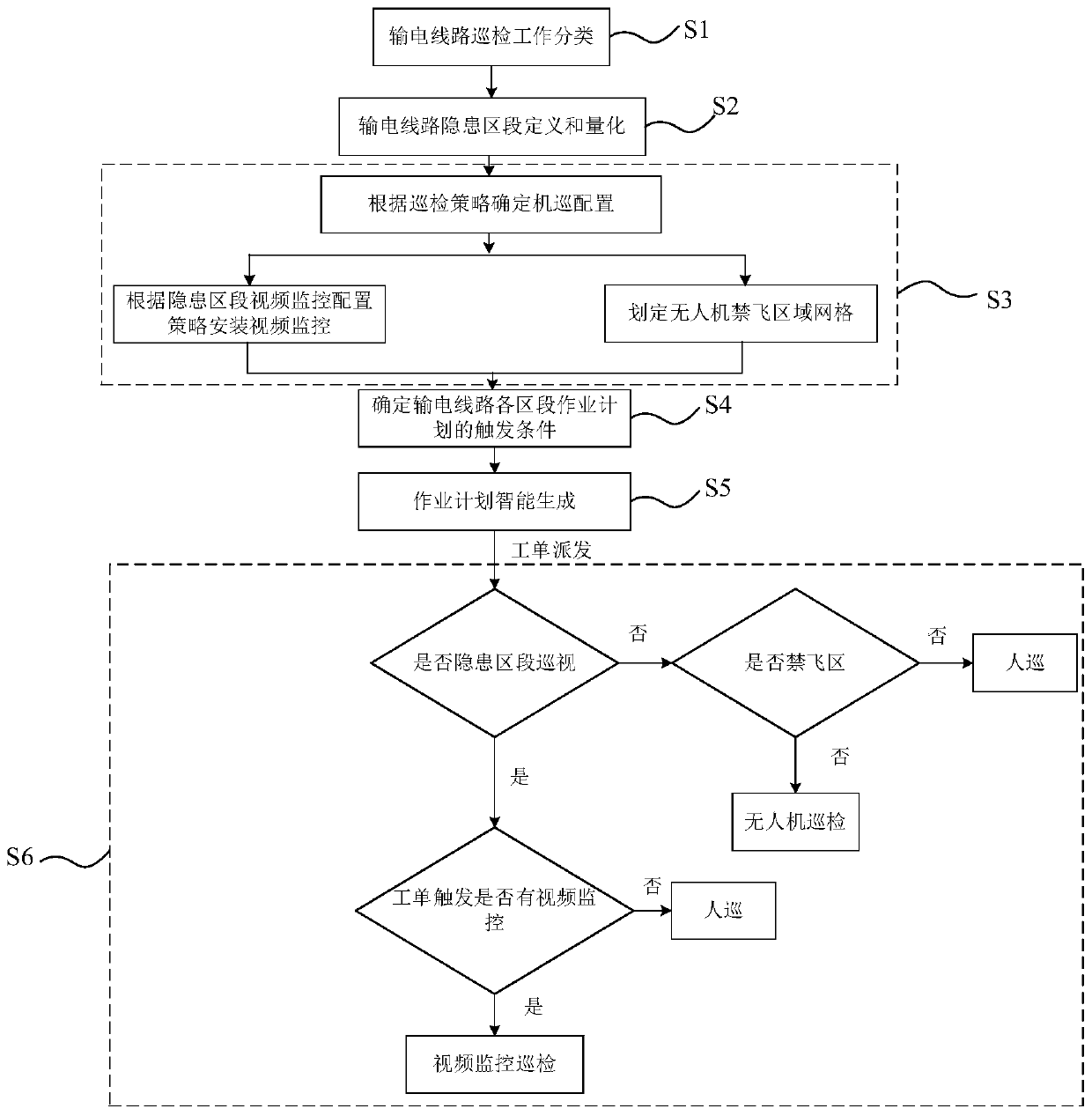

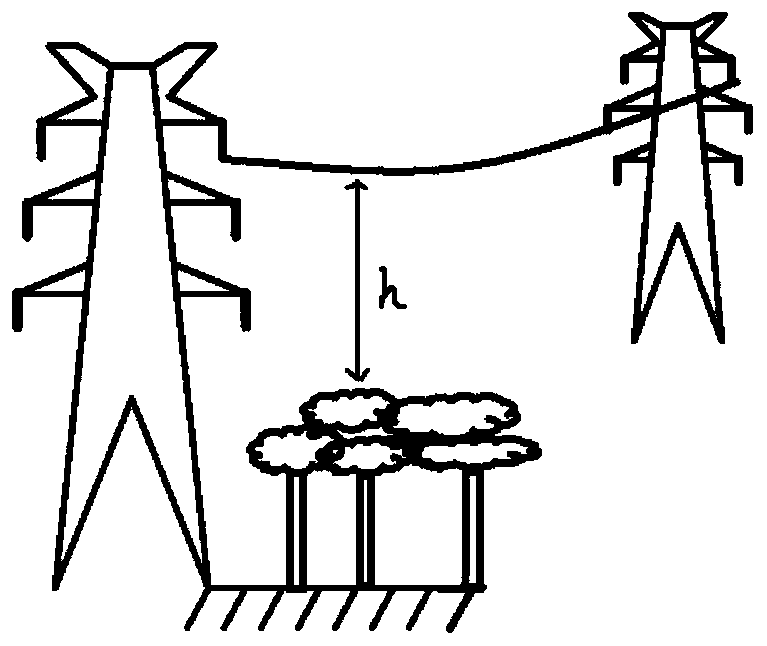

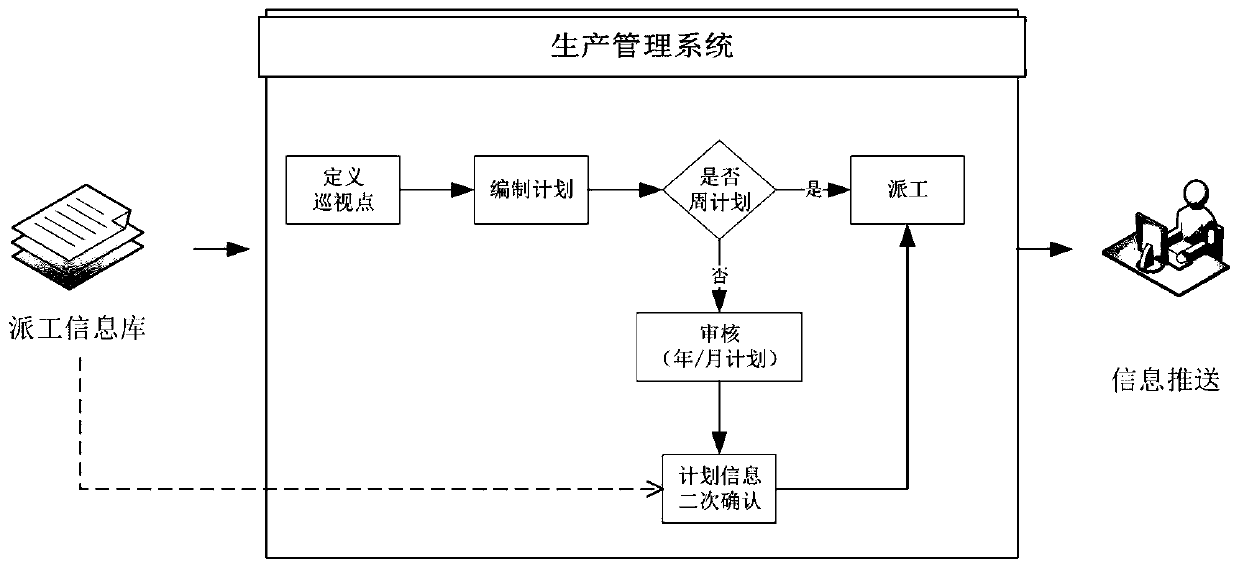

Power transmission line intelligent inspection method based on operation plan

PendingCN110111009AReduce manual workloadPromotion application value is goodResourcesTransmission lineWorkload

Owner:GUANGDONG POWER GRID CO LTD +1

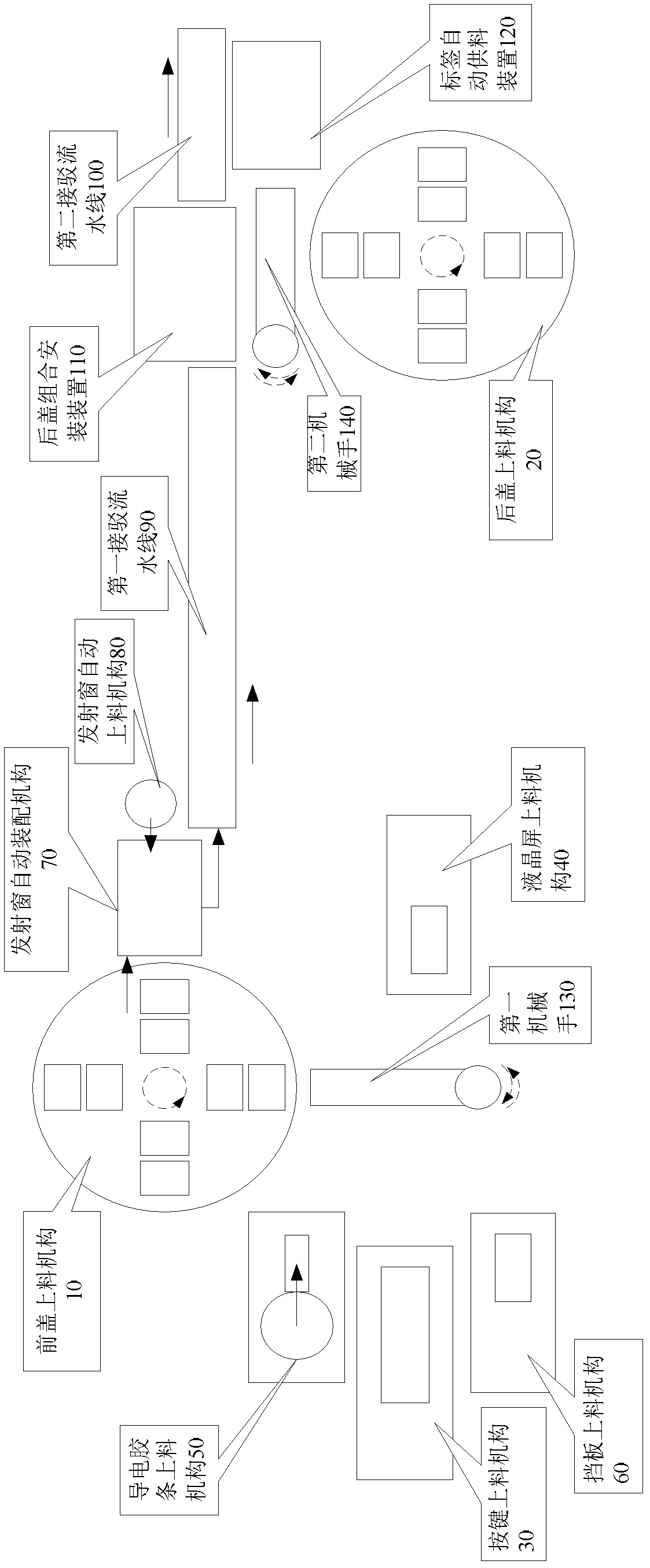

Assembly system and method for remote controller

ActiveCN103381550AImprove Consistency and ReliabilityRealize assembly automation assemblyAssembly machinesManipulatorAssembly line

The invention provides an assembly system and method for a remote controller. The assembly system comprises a first assembly unit and a second assembly unit, wherein the first assembly unit is connected with the second assembly unit through a first connection assembly line. The first assembly unit comprises a front cover loading device, a front cover fitting loading mechanism and a first mechanical hand, wherein the front cover fitting loading mechanism is arranged at the upstream of the front cover loading device; the first mechanical hand is arranged between the front cover fitting loading mechanism and the front cover loading device and used for mounting front cover fittings onto a front cover. The second assembly unit comprises a rear cover loading device and a rear cover assembly device, wherein one end of the rear cover assembly device is connected with the second end of the first connection assembly line. According to the assembly method, the first mechanical hand of the first assembly unit is used for mounting buttons, an LCD screen, conductive tapes and a baffle board onto the front cover, then mounting a launch window onto the front cover, and finally mounting the rear cover onto the front cover after the mounting of the front cover is completed.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

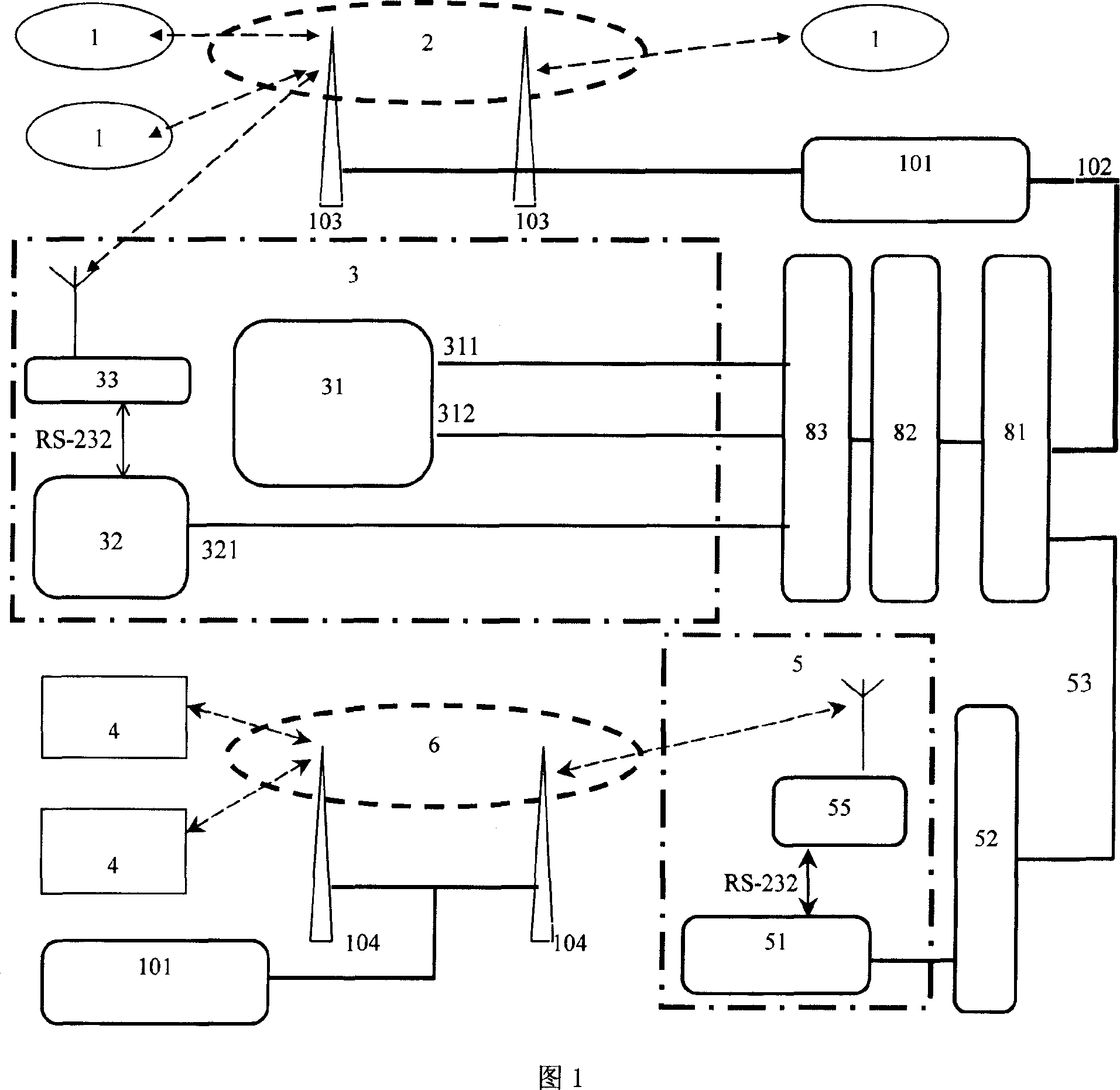

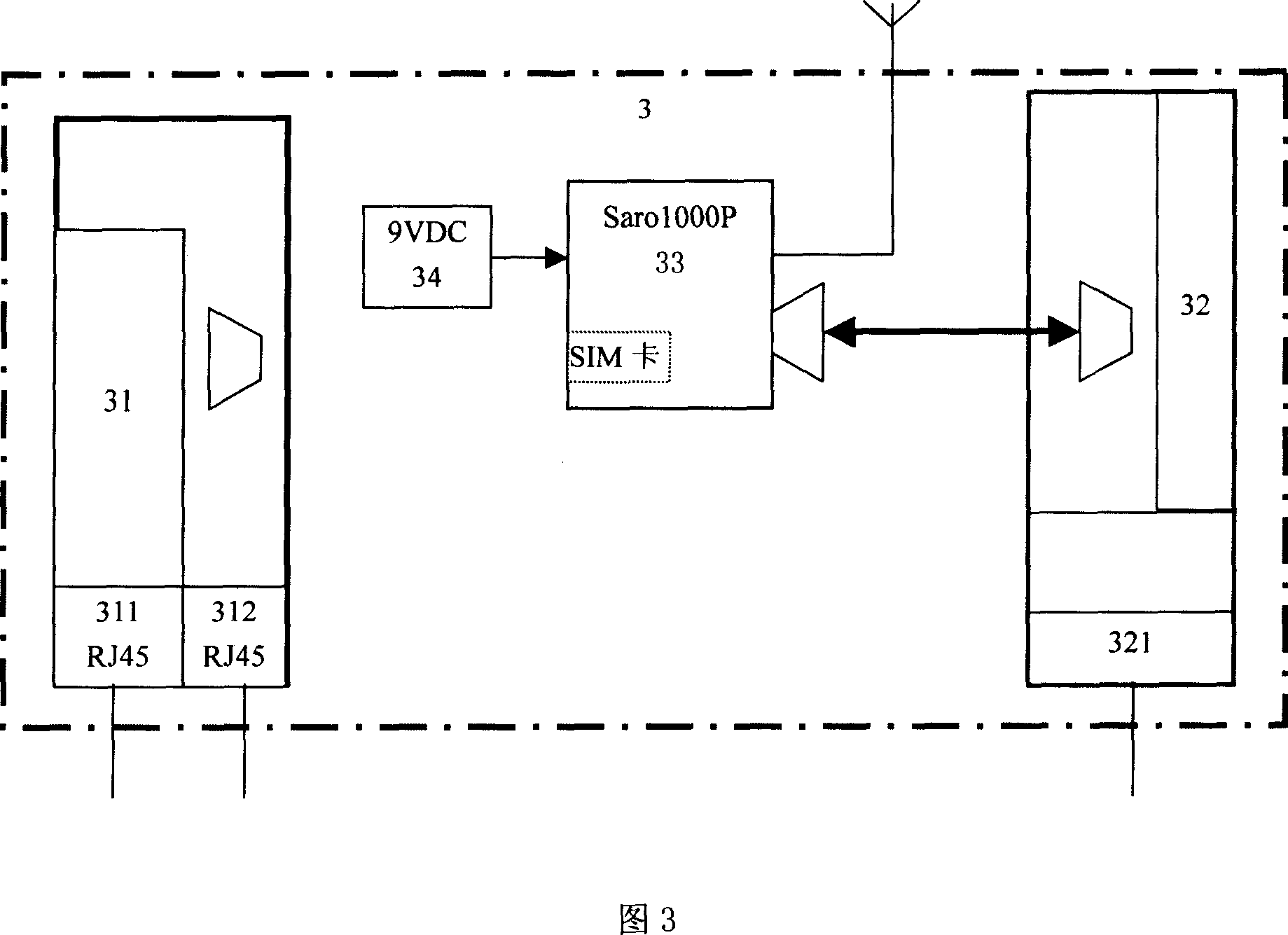

Remote monitor device for grouping data transfer water supply pipe network pump station

InactiveCN1920719AEnsure safety and stabilitySimple site installationTotal factory controlProgramme total factory controlData transmissionTerminal unit

The invention relates to a remote detector of grouped data transmission water tube network pump station, wherein it provides one GPRS detecting station which can be increased via need; the GPRS detecting station has simple address selection, simple installment and low cost, to realize online detected grouped data transmission water tube network pump station. The invention comprises water tube network remote detection distributor and area pump station detector, while the first one has tube network remote terminal, tube network wireless GPRS network, and APN special-wire network, and distributor, and the area pump station detector has pump station terminal, pump station detecting center and pump station wireless GPRS network.

Owner:厦门水务测控科技有限公司

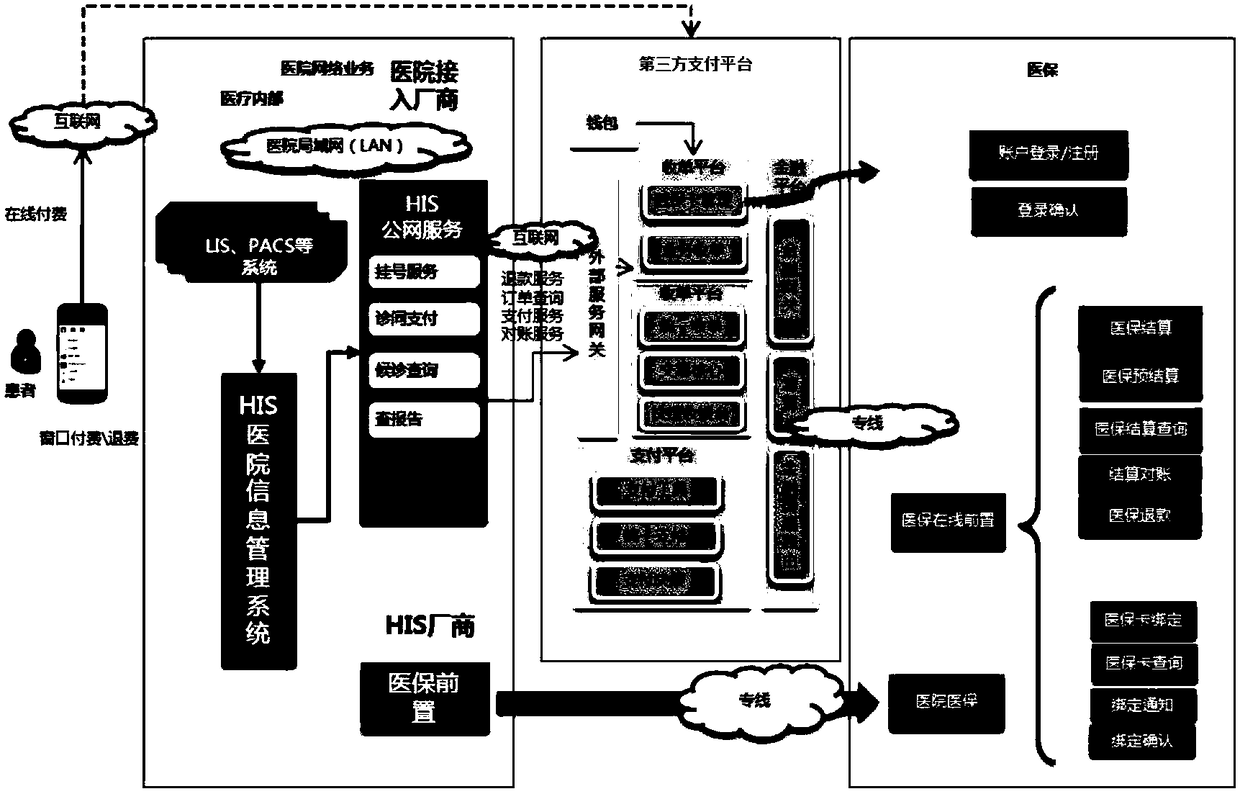

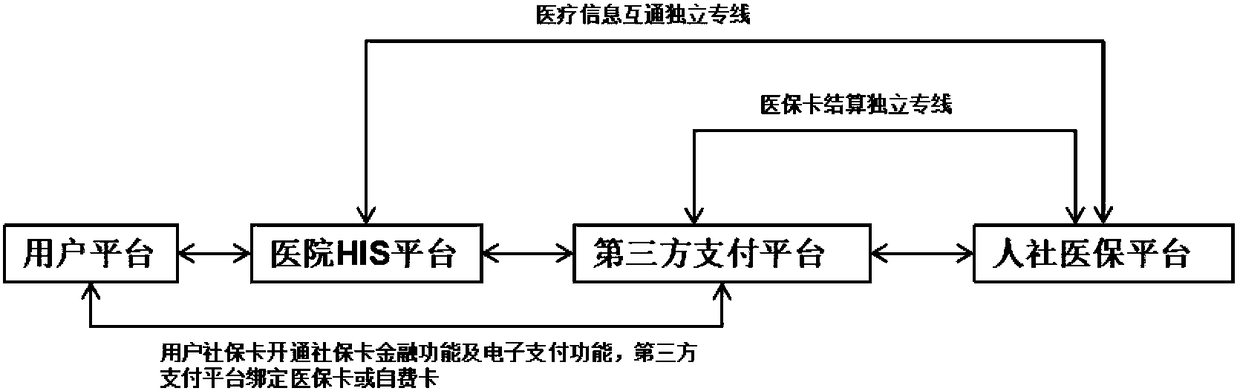

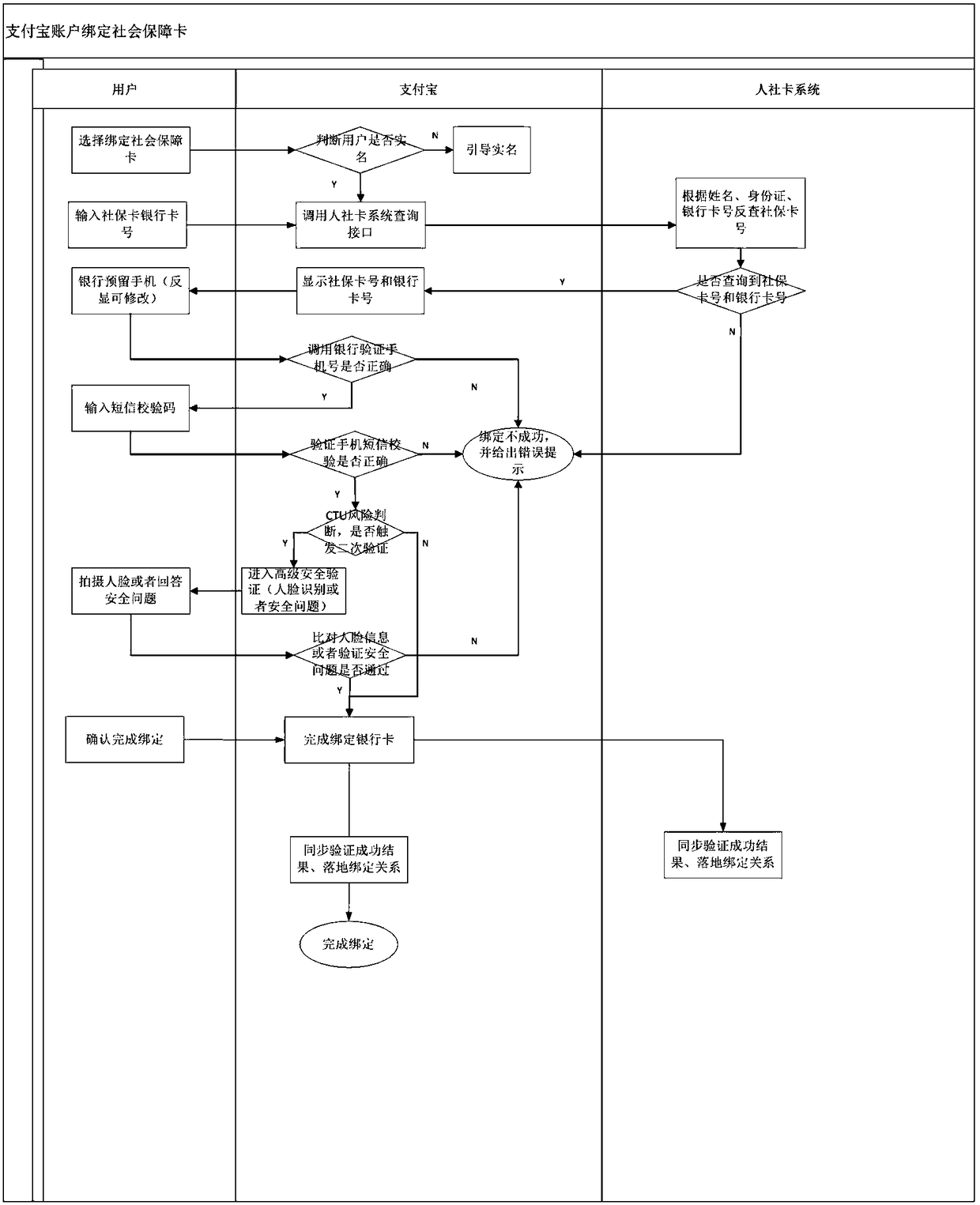

System with support of mobile payment of social security card

InactiveCN108766537AAvoid risk of leakageGuaranteed real-name authenticationFinanceDigital data protectionThird partyPayment transaction

The invention relates to a system with the support of the mobile payment of a social security card. The system comprises a hospital network service system, a third party payment platform and a medicalinsurance platform. The hospital network service system comprises an HIS hospital information management system and a mobile medical platform. The system can be conveniently and quickly connected tothe medical insurance of a mobile terminal, the real-time card-free settlement of medical insurance costs is achieved, and the payment of medical insurance reimbursable funds is not needed. At the same time, the development of a dedicated payment platform is not needed, the security of payment transactions can be ensured, the safety of each transaction is ensured to ensure the property security and information security of a user, and thus the user experience is improved at the greatest extent.

Owner:ZHENJIANG NO 1 PEOPLES HOSPITAL

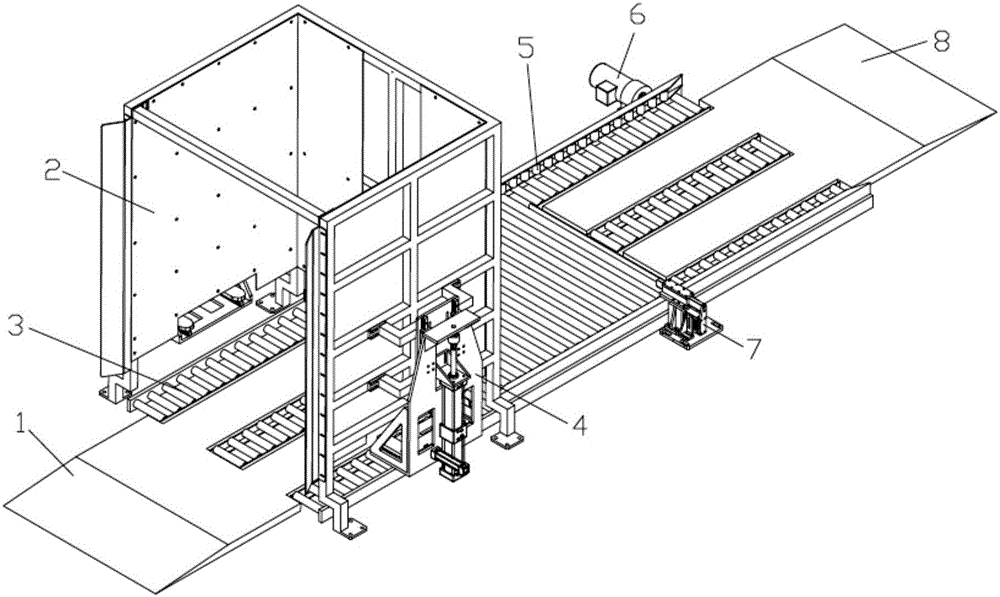

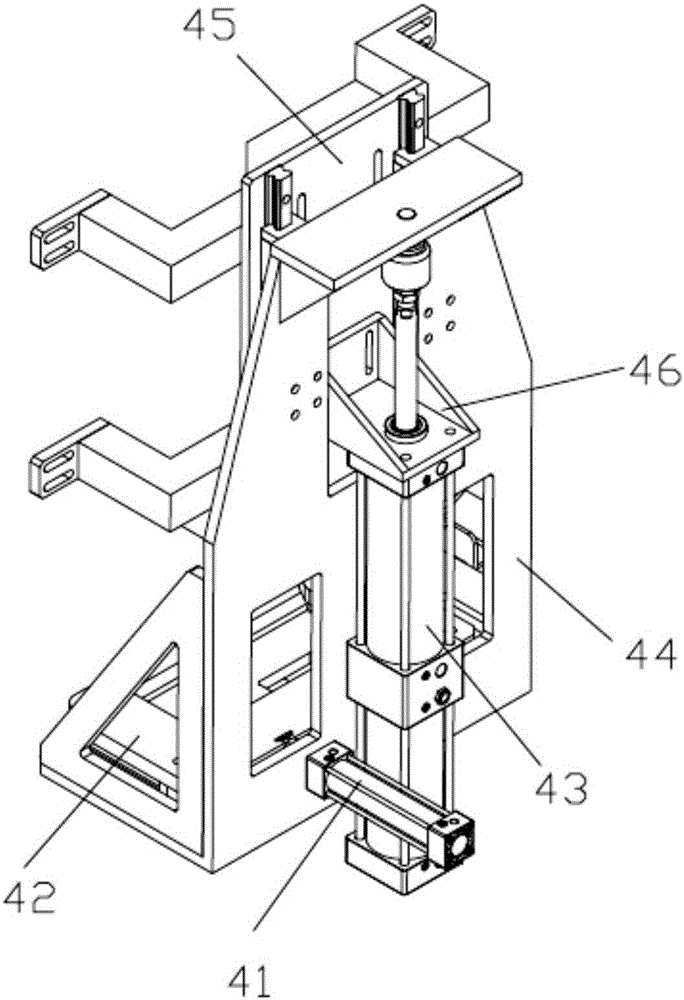

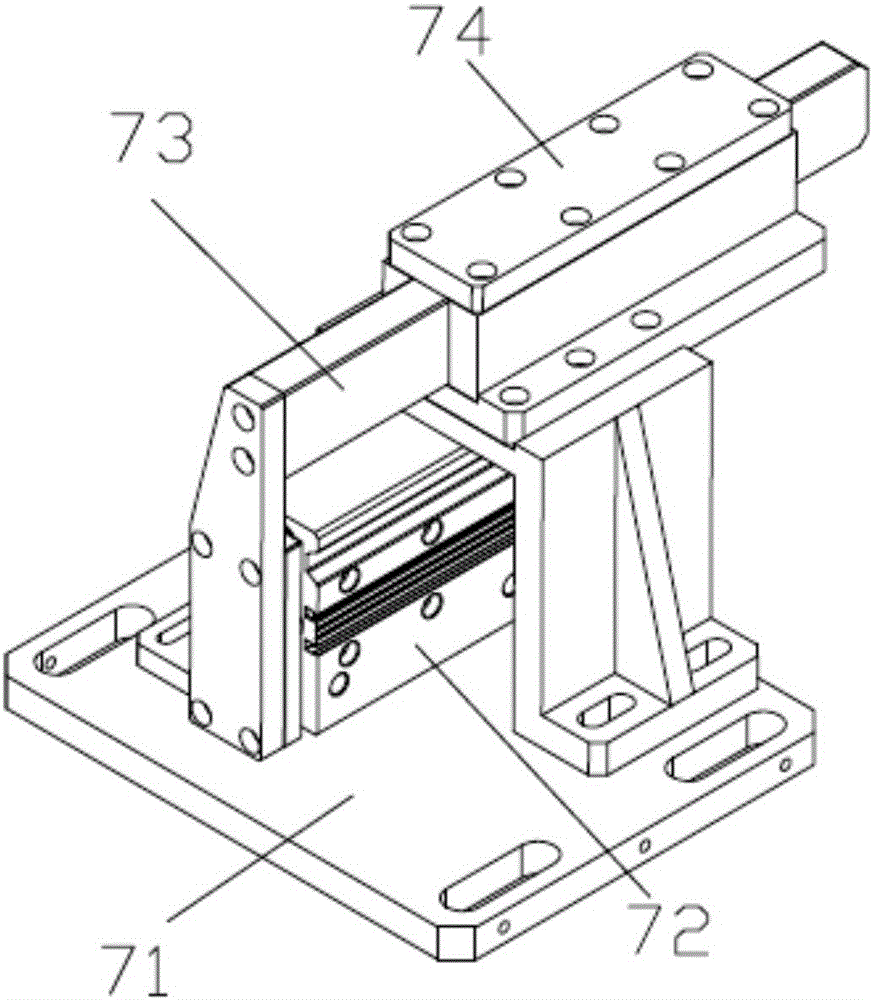

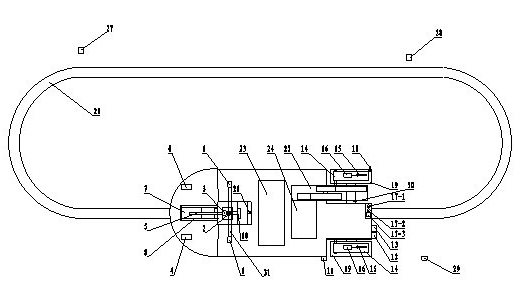

Storage and distribution device for pallets

InactiveCN105775722ASolve the automatic supply problemFully automatedDe-stacking articlesConveyor partsEngineeringWorkload

The invention discloses a storage and distribution device for pallets. The storage and distribution device comprises a bottom plate. A pallet storage frame (2) is arranged on the bottom plate. The pallets piled into stacks are arranged in the pallet storage frame (2). Ejecting mechanisms (4) which can lift up the rest of the pallets except the pallet at the bottommost end each time are arranged on the two sides of the panel storage frame (2). The pallet at the bottommost end can be conveyed forwards along with a conveying roller arranged on the bottom plate. The storage and distribution device for the pallets is high in automation degree, and capable of storing and automatically distributing the pallets, reducing workloads of workers and improving efficiency.

Owner:HANDAN MIDEA REFRIGERATION EQUIP +2

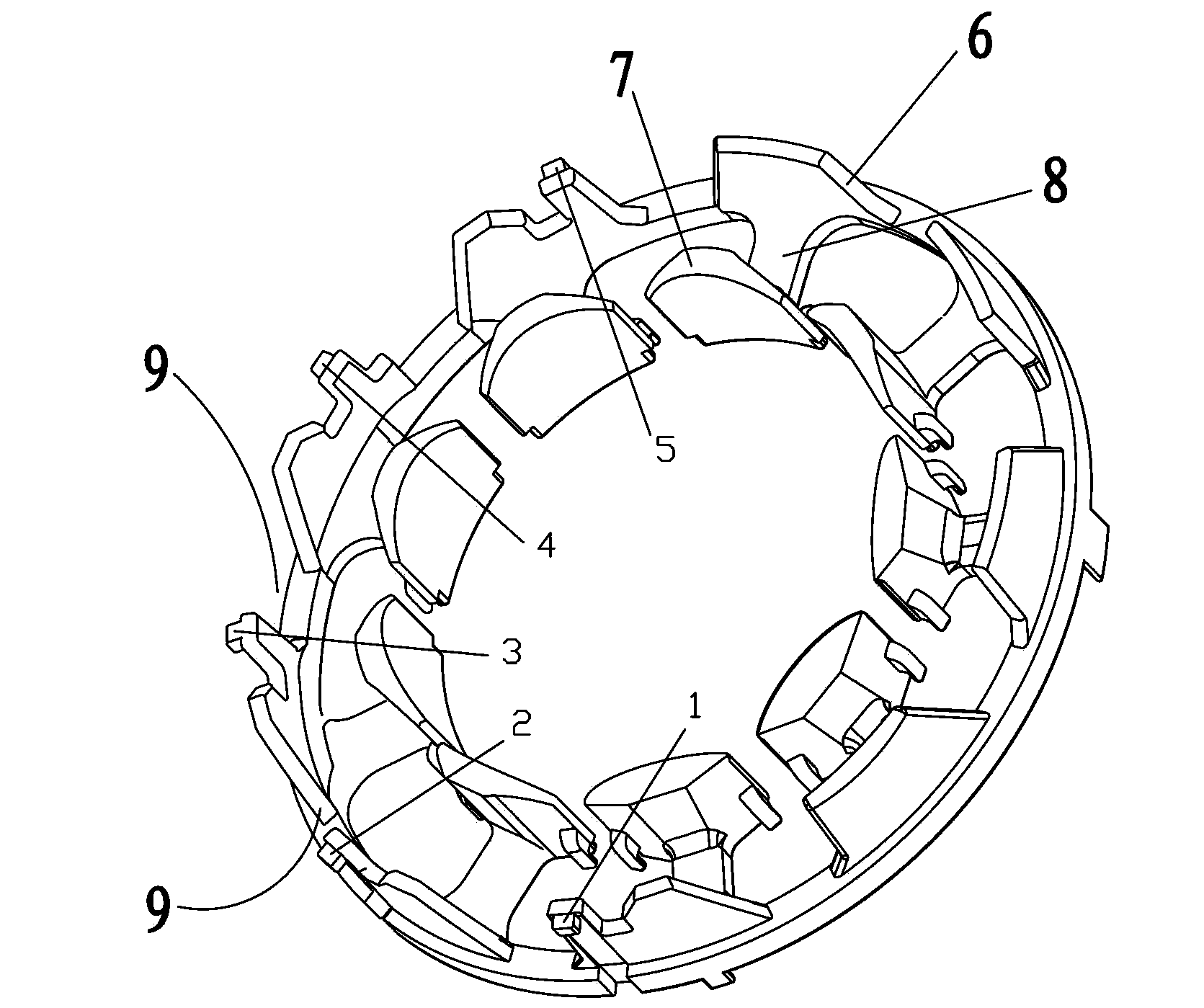

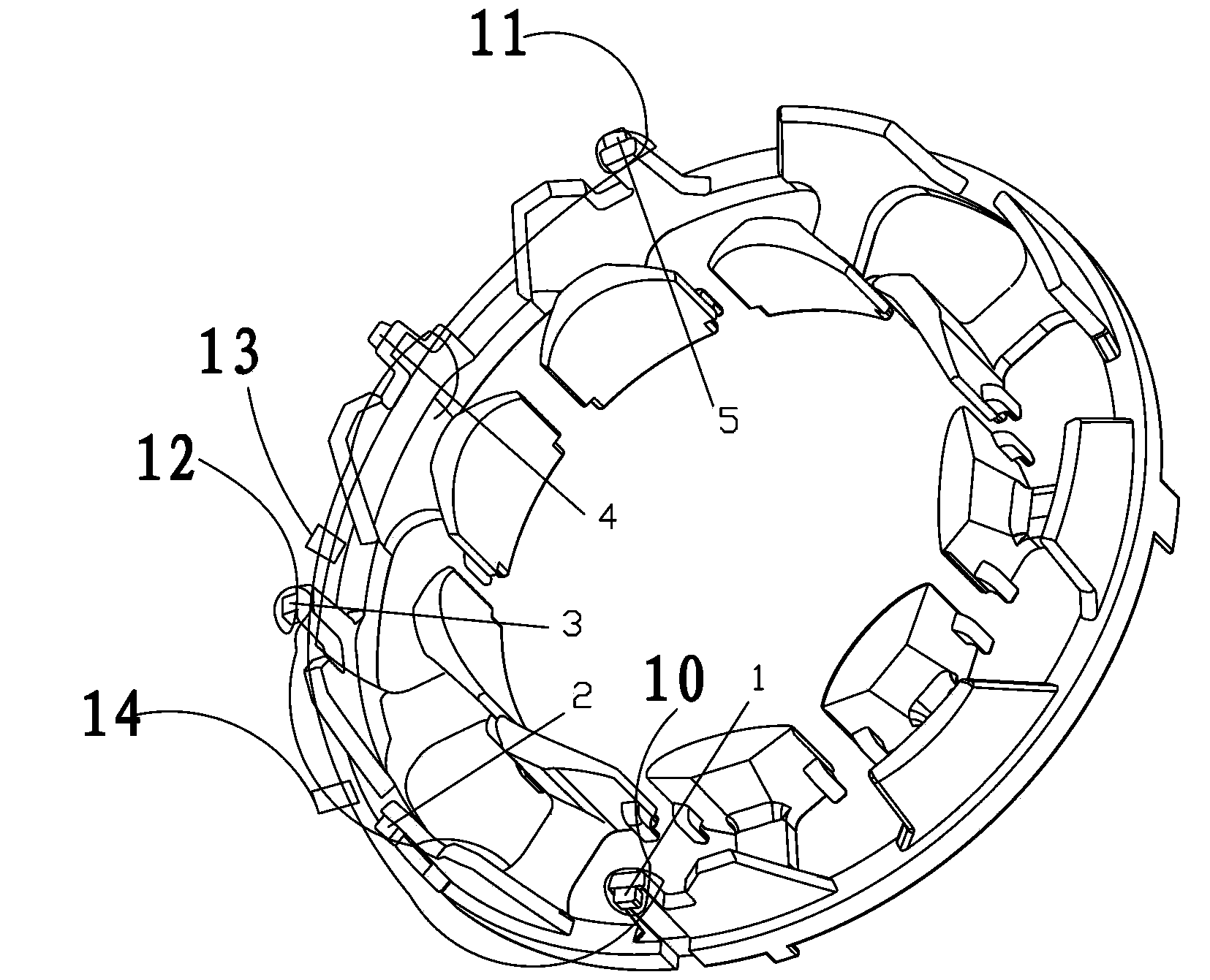

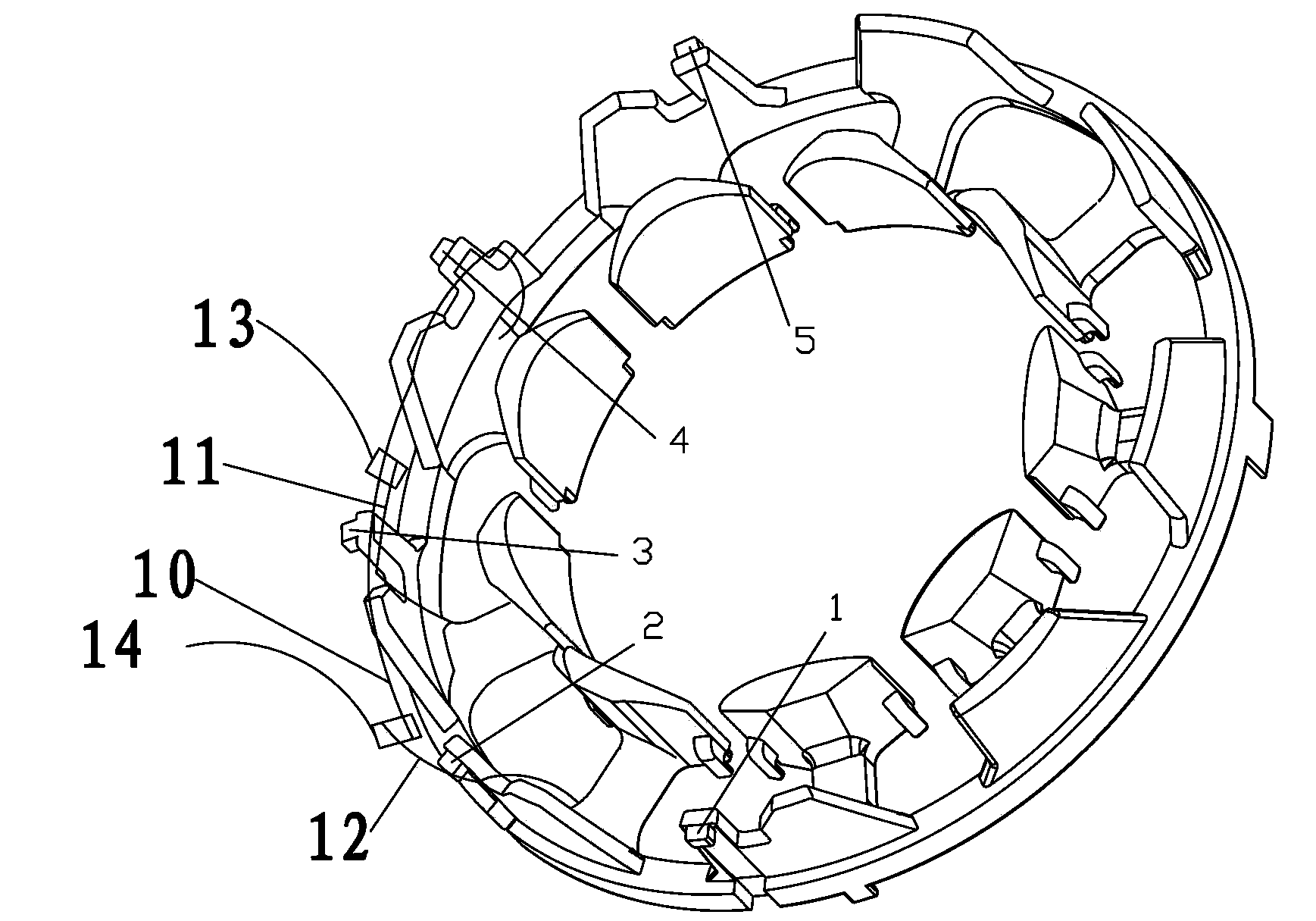

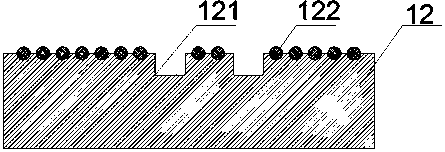

In-series concentrated wound motor public end processing method and motor insulating framework

ActiveCN103701241AImprove efficiencyImprove operational reliabilityWindingsManufacturing dynamo-electric machinesMotor insulationEngineering

The invention discloses an in-series concentrated wound motor public end processing method and a motor insulating framework. The motor insulating framework is of a circle structure, is used for fixing a three-phase wounding and comprises an outer side wall, an inner side wall and a bottom plate, wherein the outer side wall and the inner side wall are connected through the bottom plate; the outer side wall is provided with a plurality of U-shaped open grooves for holding puncture terminals communicated with any two wound lines of the three-phase wounding in a riveting manner; boss buckling points are arranged between every two adjacent open grooves; the boss buckling points are used for positioning any one wound line of the three-phase wounding. The processing method adopts the motor insulating framework and comprises the following steps: respectively communicating any one wound line of the three-phase wounding with the other two wound lines through the puncture terminals in a riveting manner; putting the puncture terminals at the opening grooves in the outer side wall of the motor insulating framework after being communicated with two wound lines in the riveting manner; positioning any one of the wound lines of the three-phase wounding through the boss buckling points on the outer side wall of the insulating framework. By adopting the processing method, the efficiency in motor production and the operation reliability of the motor are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

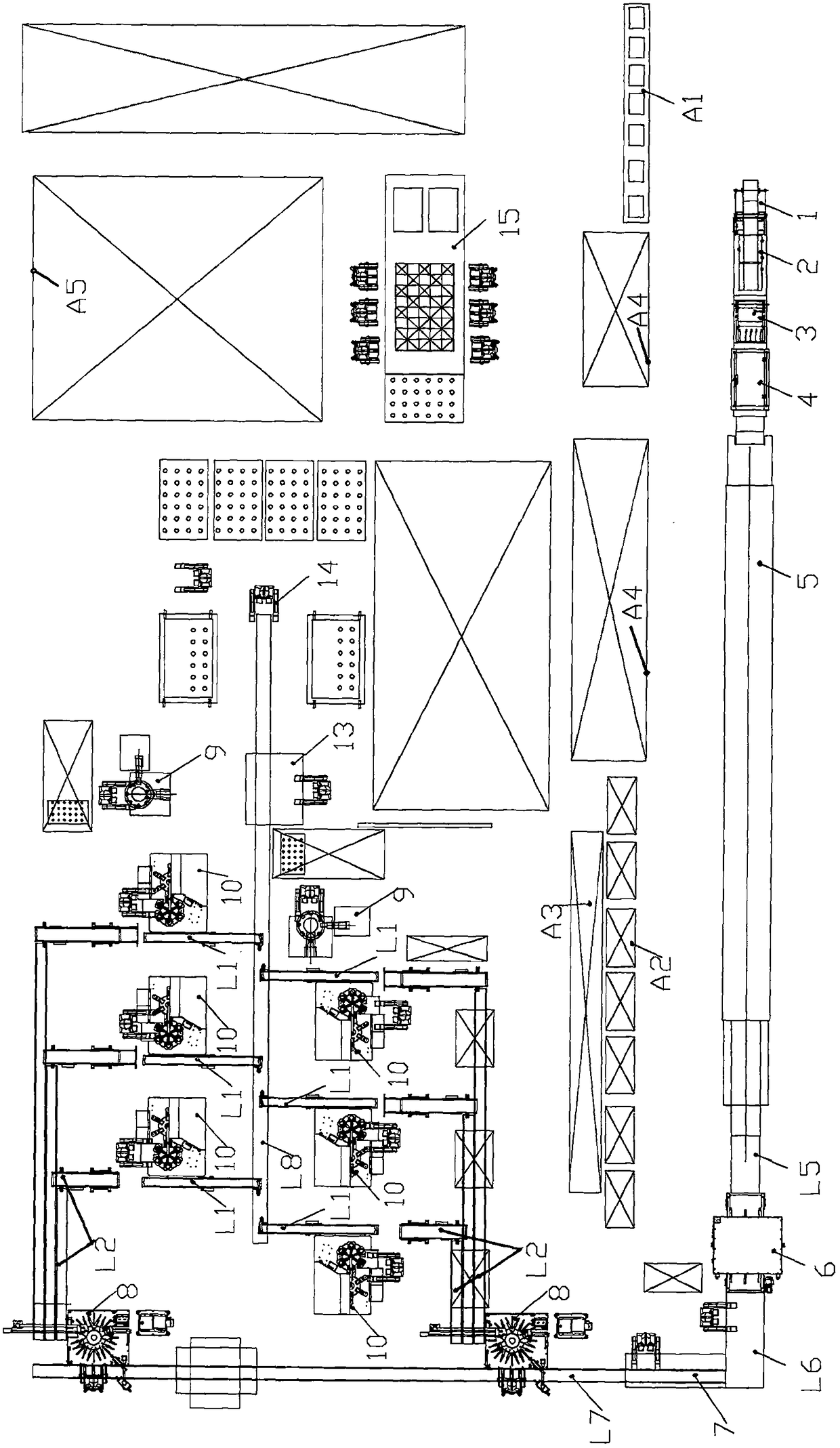

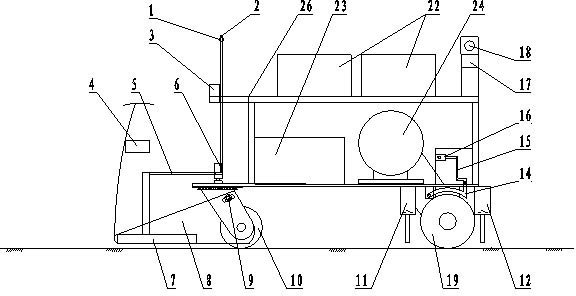

Environmental-friendly automatic intelligent filter element production line and production process thereof

ActiveCN108749144AAvoid damageAchieving the goal of reducing staff and increasing efficiencyPaper/cardboard articlesTotal factory controlProduction lineProcess engineering

The invention relates to an environmental-friendly automatic intelligent filter element production line and a production process thereof. The environmental-friendly automatic intelligent filter element production line comprises a filter paper slitting work station, a filter paper heating work station, a filter paper folding work station, and a filter paper shaping work station. A filter paper curing work station (5), a filter paper cutting work station (6) and a filter paper one-piece stripping work station (7) are sequentially arranged on the side part of the filter paper shaping work station; the filter paper one-piece stripping work station is connected with a filter paper holding strip edge sealing work station (8); and a filter element end cover welding work station (10) and a plasticend cover welding work station (9) are arranged on the side edge of the filter paper holding strip edge sealing work station. A filter element inspection work station (13) and a filter element discharging work station (14) are sequentially arranged subsequently. According to the environmental-friendly automatic intelligent filter element production line and the production process thereof providedby the invention, products are prevented from falling to the ground, laying and overstocking, synchronous online production and production task arrangement of multiple species of products can be arranged at a time according to the sequence of customer orders, and the product quality and the production process control are improved.

Owner:ZHEJIANG UNIVERSE FILTER

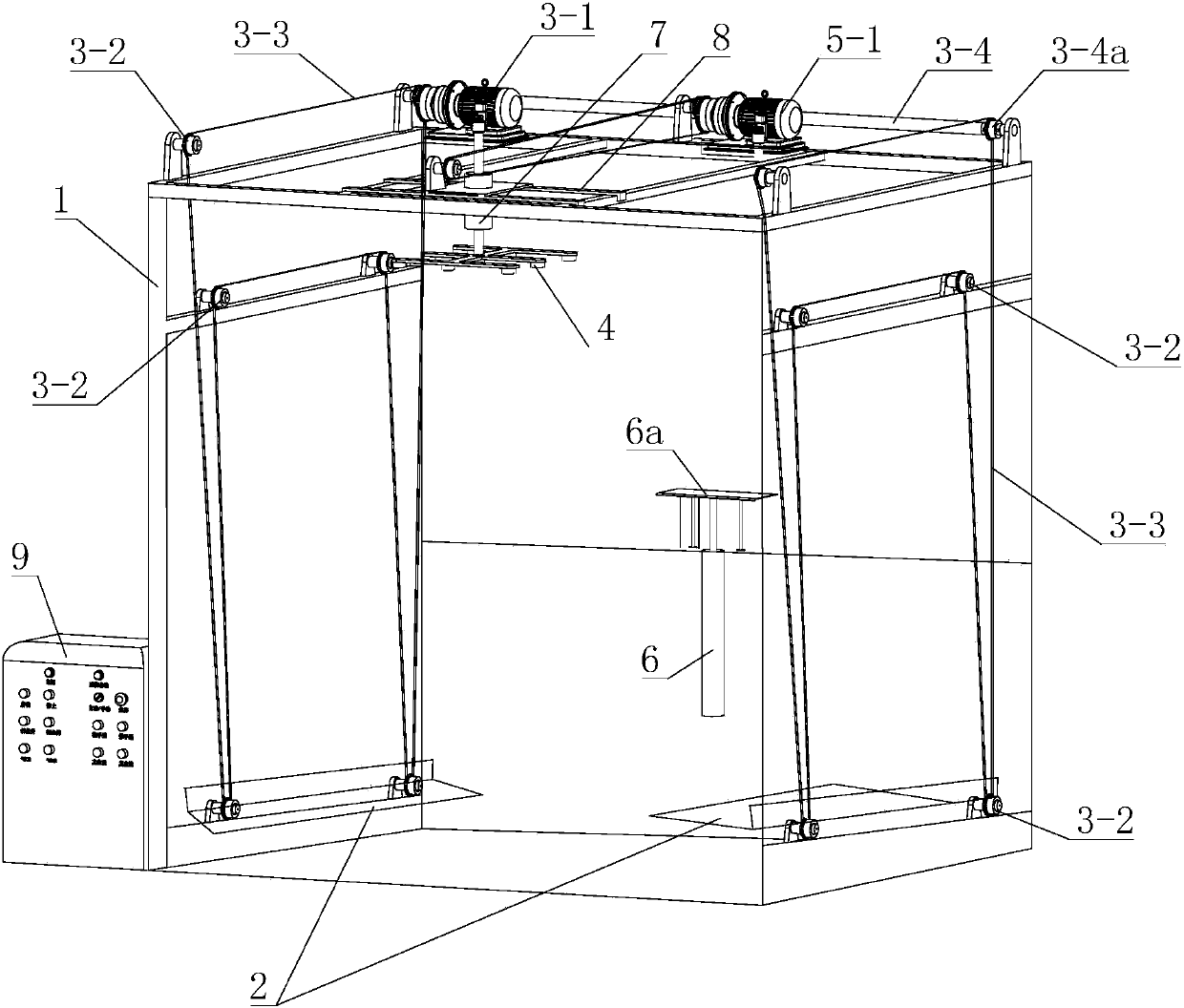

Automatic feeding device of air conditioner indoor unit bottom support

ActiveCN103723514AIncrease usageHigh degree of automationPortable liftingConveyor partsControl engineeringMachine

An automatic feeding device of an air conditioner indoor unit bottom support comprises a machine frame, trays arranged on the left and the right of the inside of the machine frame, a tray moving mechanism arranged on the machine frame, a sucker located at the top of the machine frame, a sucker moving mechanism arranged on the machine frame, a downward sliding cylinder arranged on the rear portion of the machine frame and a control box, wherein the tray moving mechanism controls the trays to move up and down in the longitudinal direction; the sucker is arranged on a sliding frame, and the sliding frame can move along a guide rail at the top of the machine frame; the sucker moving mechanism controls the sliding frame to move forwards and backwards on the guide rail in a reciprocating mode; the top of the downward sliding cylinder is provided with a supporting plate; the control box controls the tray moving mechanism, the sucker, the sucker moving mechanism and the downward sliding cylinder to work. The automatic feeding device is high in automation degree, can replace manual transportation operations, saves labor, is efficient and beneficially reduces production cost.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

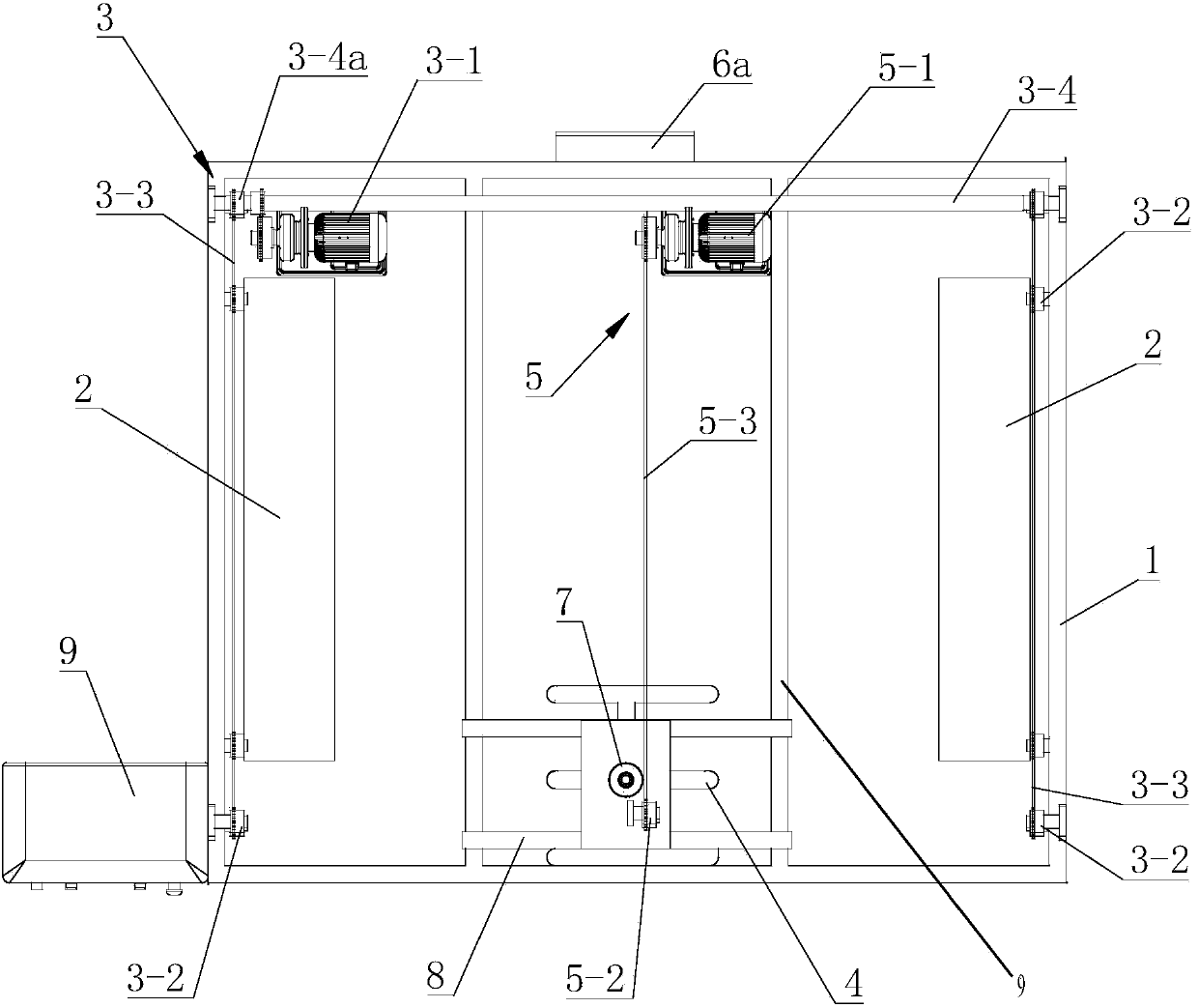

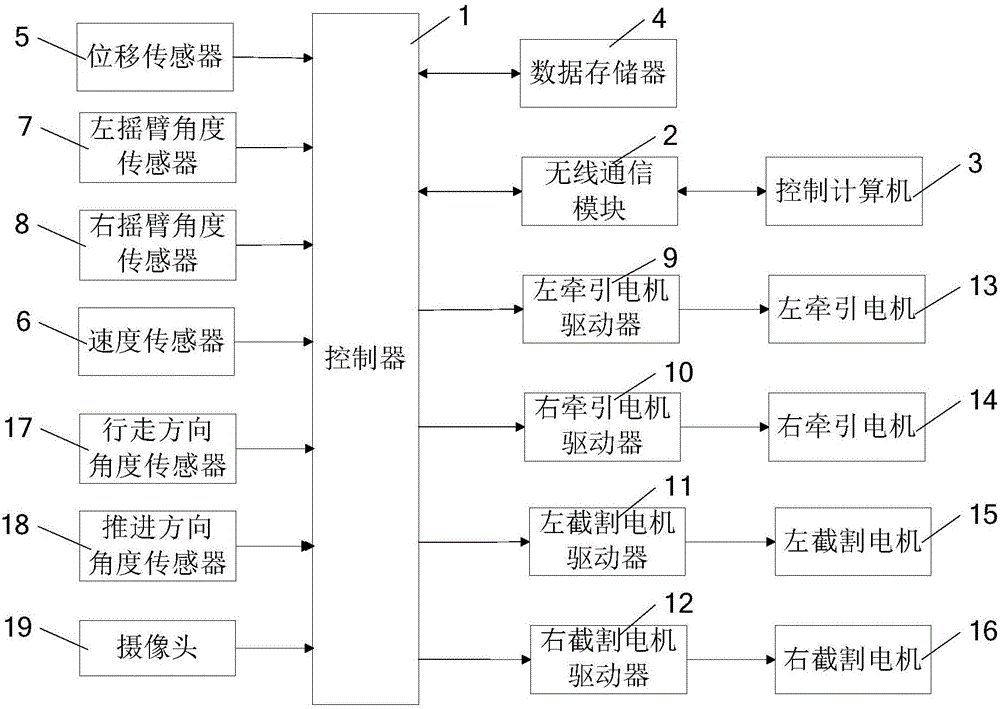

Coal mining machine coal mining control method with automatic coal cutting being primary and remote interference being auxiliary

ActiveCN106368699AThe method steps are simpleReasonable designSlitting machinesControl systemEngineering

The invention discloses a coal mining machine coal mining control method with automatic coal cutting being primary and remote interference being auxiliary. A coal mining machine is a double-roller coal mining machine. A control system adopted by the method comprises a controller, a wireless communication module, a control computer, a data storage device, a camera, a displacement sensor, a left rocker arm angle sensor and a right rocker arm angle sensor. The coal mining machine mining control method comprises the following steps that first, demonstration is conducted manually; and second, the coal mining machine is controlled to conduct coal mining with automatic coal cutting being primary and remote interference being auxiliary, specifically, in the automatic coal cutting process through the coal mining machine, when an operator judges that the posture of the coal mining machine needs to be adjusted manually, the operator conducts manual interference control to adjust the coal cutting posture of the coal mining machine, and after adjustment is completed, remote manual interference is stopped, and the automatic coal cutting posture of the coal mining machine restores. According to the coal mining machine coal mining control method with automatic coal cutting being primary and remote interference being auxiliary, the steps are simple, the design is reasonable, the method is convenient to implement, the purposes of staff reduction and efficiency improvement are achieved, the safety coefficient is increased, the practicality is high, and popularization and application are facilitated.

Owner:XIAN COAL MINING MACHINERY

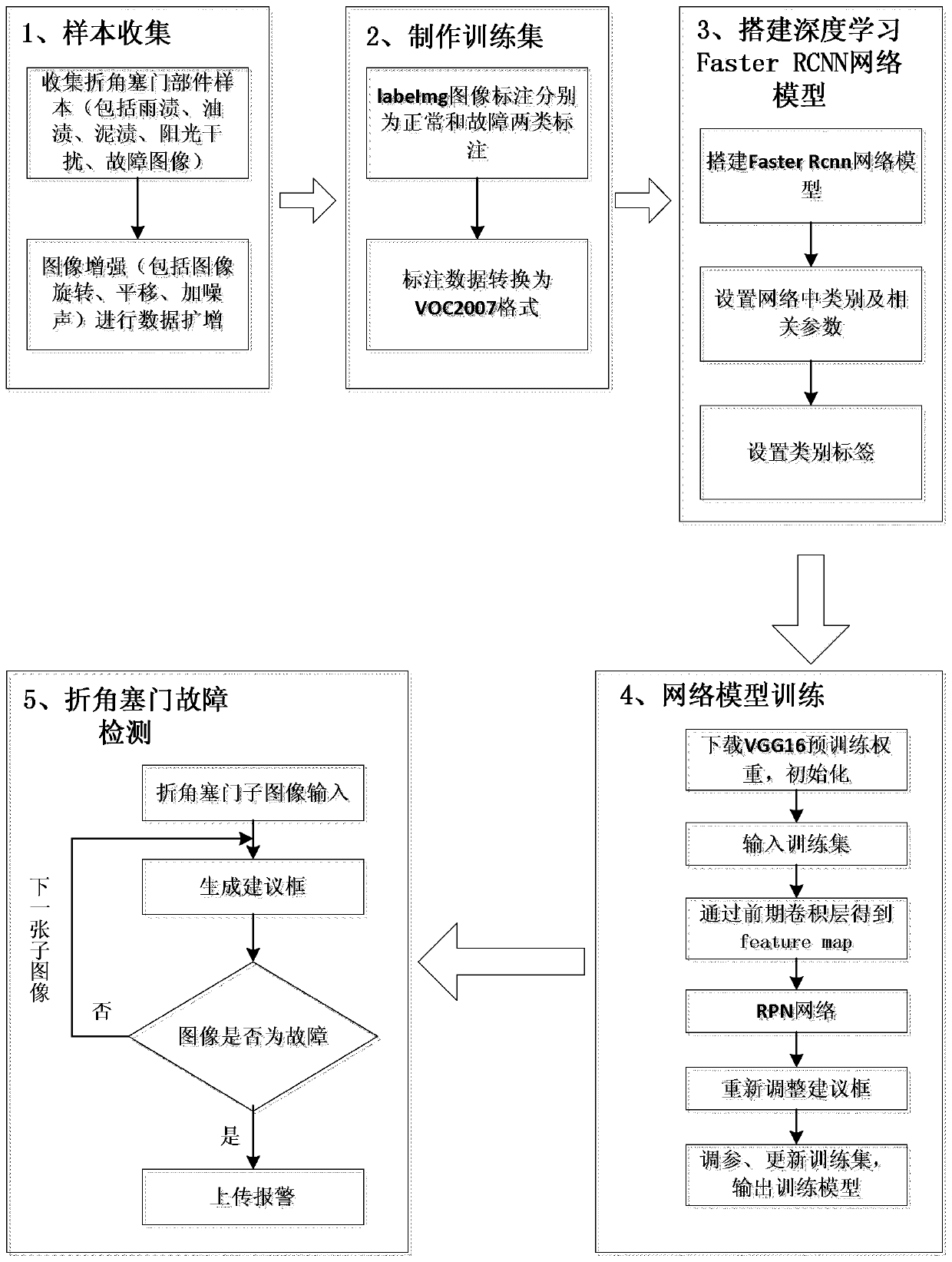

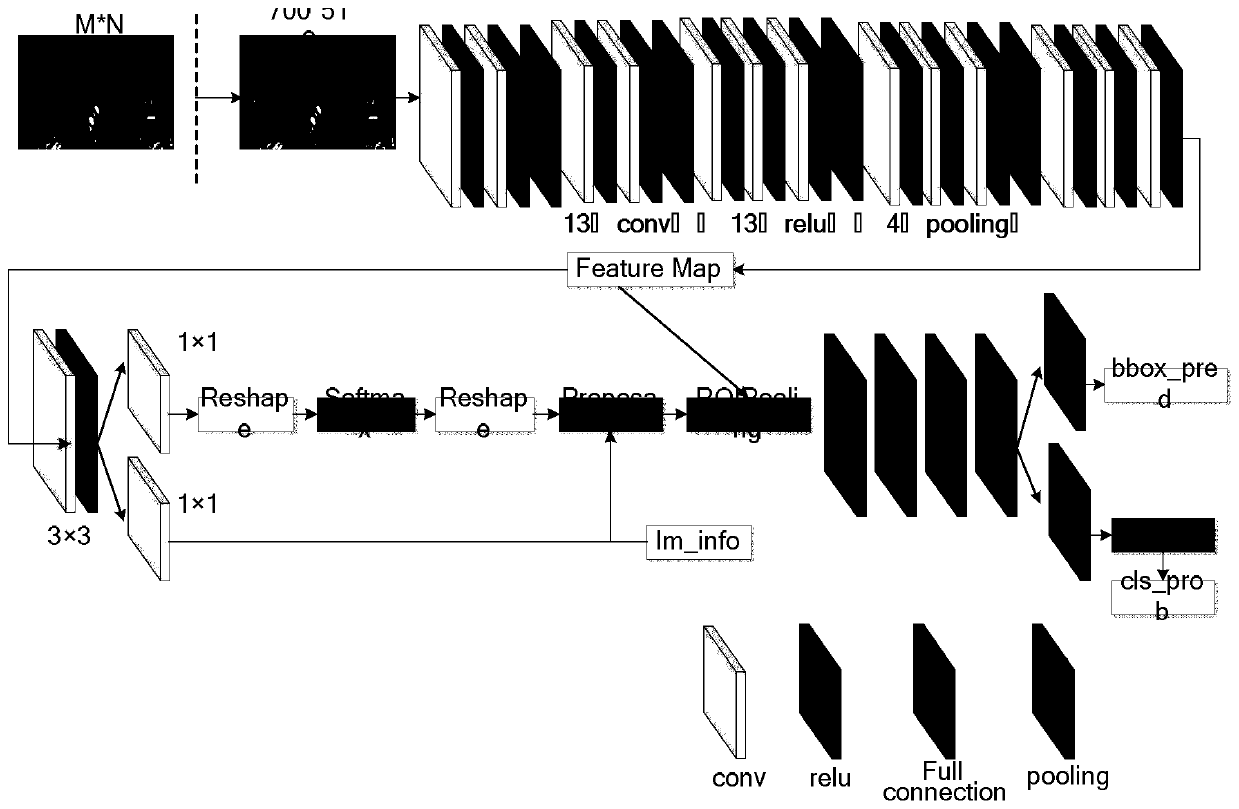

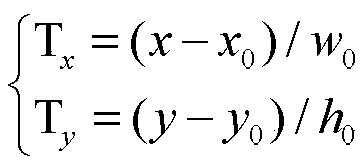

Recognition method for closing fault image of wagon angle cock handle

InactiveCN111091552AIncrease flexibilityImprove universalityImage enhancementImage analysisImaging processingAlgorithm

The invention discloses a recognition method for a closing fault image of a wagon angle cock handle, belongs to the field of railway image processing, and aims to solve the problems of false detectionand missing detection of an existing fault detection method for wagon angle cocks. The method comprises the following steps: step 1, establishing an angle cock handle image data training set; step 2,building a Faster RCNN network model; step 3, training the network model: inputting the training set in the step 1 into the Faster RCNN network module in the step 2 for training; and step 4, carryingout fault prediction on the vehicle passing image of the wagon angle cock handle by using the trained Faster RCNN network model.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

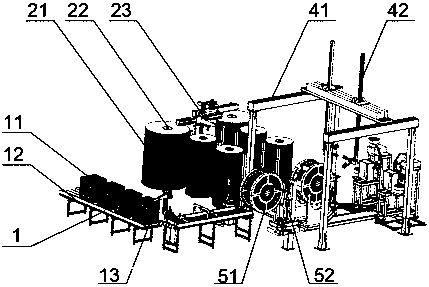

Automatic feeding device of UO2 grinding pellets

ActiveCN108274389ARealize localizationImprove work efficiencyGrinding feedersGrinding work supportsMotor driveEngineering

The invention discloses an automatic feeding device of UO2 grinding pellets. The automatic feeding device of the UO2 grinding pellets comprises a boat unit robot, a pellet robot, a boat unit feeding machine, a molybdenum boat plate discharging machine, a disk dismounting machine and a corrugated plate discharging machine. The automatic feeding device of the UO2 grinding pellets is characterized inthat the automatic feeding device can automatically complete material transferring and disk dismounting tasks, and the blank of related technologies in China is filled up. Servo motor drive and air cylinder transmission are mainly adopted to complete pellet conveying and disk dismounting. Transferring of molybdenum boat plates with materials and empty molybdenum boat plates is completed through the boat unit robot. Transferring of corrugated plates with the materials is completed through the pellet robot. Transferring of empty corrugated plates is completed both through the boat unit robot and the pellet robot. The disk dismounting machine mainly conveys the pellets to a track. At present, the automatic feeding device is applied to a pellet preparation production line, about 1,100 vehicles of pellets are produced, the percent of pass conforms to the requirement of the quality of ground pellets, the functions of the equipment are stable and reliable, and the producing and using requirements are met.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

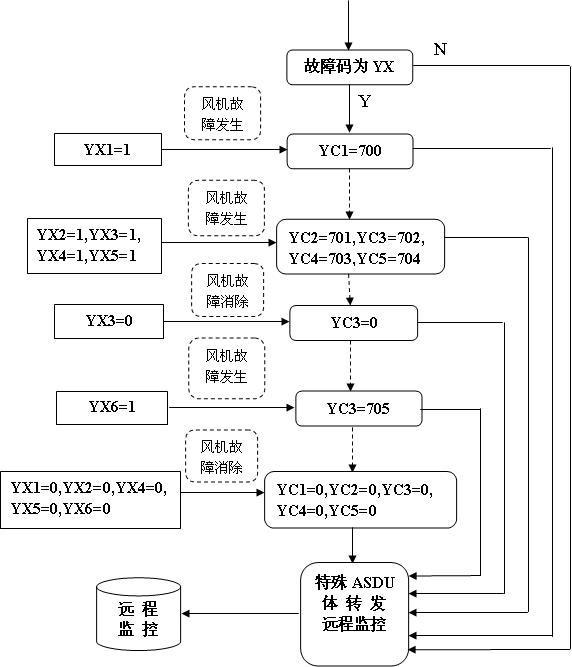

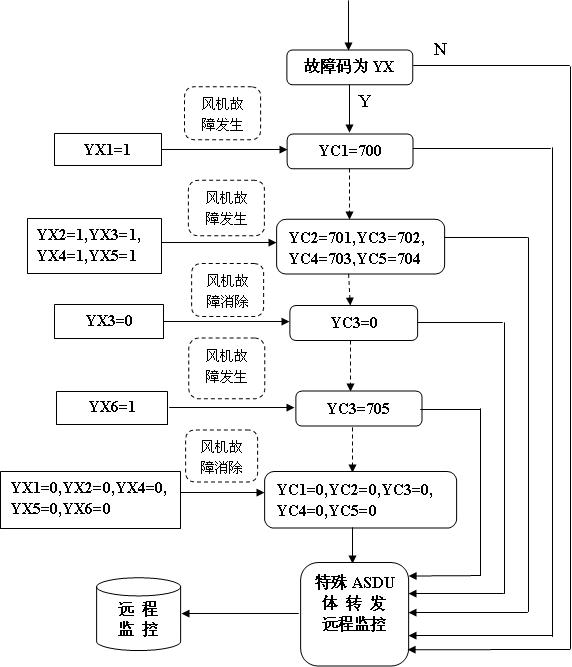

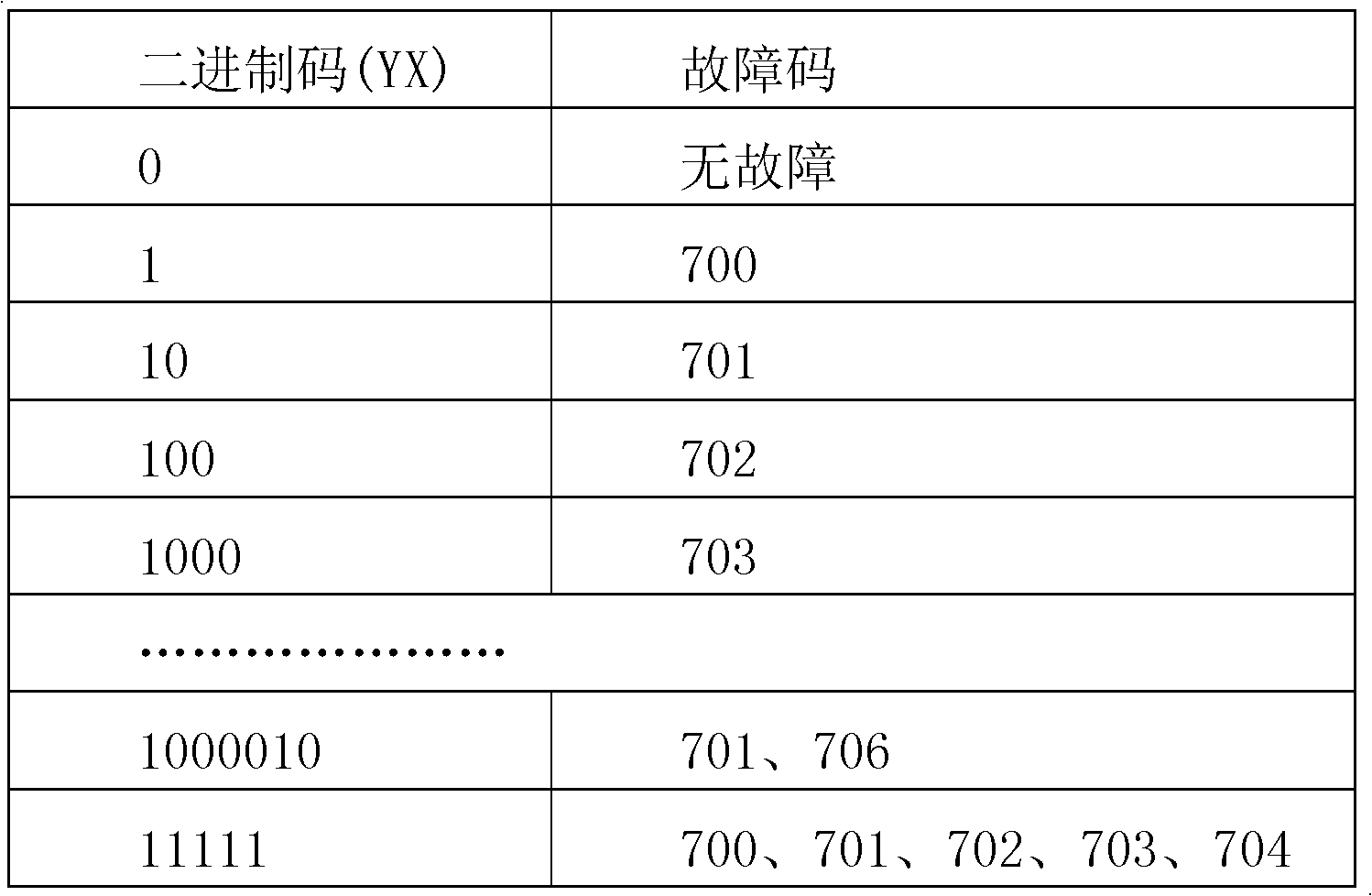

Unified modeling method based on state data and fault data of fan of wind power plant

InactiveCN102331775AEnsure timeliness and accuracyImprove the correctness of fault diagnosisElectric testing/monitoringFailure dataPower station

The invention discloses a unified modeling method based on the state data and fault data of a fan of a wind power plant. The method comprises the following steps of: classifying and aggregating the acquired state data and fault data of the fan; converting the state data or the fault data, which is reported with analog quantity, of the fan into telemetry data, and forwarding the telemetry data to a remote monitoring system; filling the state data or the fault data, which is reported with switching quantity, of the fan into a library in a remote signaling data form; and converting the state data or the fault data of the fan into the telemetry data by using an intelligent conversion method, and forwarding the telemetry data to the remote monitoring system. In the method, a process of converting the switching quantity into the analog quantity for the type of a state code or a fault code of a single fan is provided; concurrent faults of the fault code of the fan in the same time are reasonably and effectively processed; and the operating state and fault state of the fan can be timely and accurately reported, so the data, of different types, of the fan can be subjected to unified analysis, statistics and management through remote monitoring, the accuracy of fault diagnosis of the remote monitoring system of the fan is improved, the working intensity of a monitoring person is reduced, and working efficiency is improved.

Owner:NARI NANJING CONTROL SYST

Network service program monitoring method

InactiveCN108334389AMaintain normal operationsReduce staff on dutyClosed circuit television systemsTransmissionRemote computerLocal area network

The invention discloses a network service program monitoring method. The method includes remote system control which is technology of remotely controlling another computer by a computer in a network;remote system control generally refers to controlling a far-end computer through a network, and remote control refers to remote control in a local area network in most cases; when an operator uses a main-control-end computer to control a controlled-end computer, it is like sitting in front of the controlled-end computer; application programs of the controlled-end computer can be started, file dataof the controlled-end computer can be used or stolen, printing and access to the Internet can be realized by utilizing outside printing equipment and communication equipment of the controlled-end computer, it is like utilizing a remote controller to remotely control volume, channel changing or switching on and off of a TV, and the main-control-end computer only needs to transmit instructions of akeyboard and a mouse to a remote computer.

Owner:广州源计划网络科技有限公司

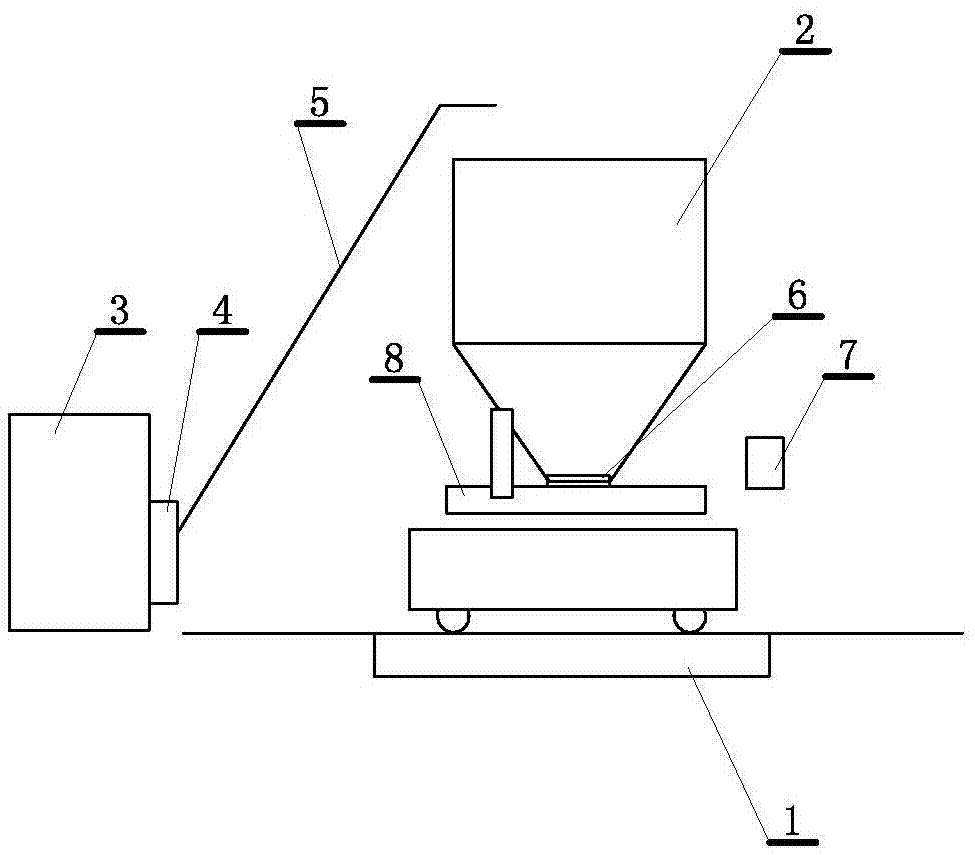

Self-service automobile loading system and method for coal mine

InactiveCN107487644AReduce construction costsLow investment costLoading/unloadingControl circuitSelf-service

The invention discloses a self-service automobile loading system and method for coal mine. The system comprises a weighing automobile scale arranged on the ground surface. A material storage bin is arranged above the weighing automobile scale. A feeding port of the material storage bin is connected with a feeder of a washing center through a conveying belt. A discharging gate is arranged at a discharging port of the material storage bin. A controller box is further arranged above the weighing automobile scale through a suspending mechanism. Operation buttons are arranged on the controller box. A system server is connected with the weighing automobile scale and a control circuit in the controller box. The system server is connected and controls the discharging gate through a PLC. By means of the self-service automobile loading system and method for the coal mine, a driver can drive an empty automobile to run to an automobile scale weighing platform below a loading station, the driver does not need to get off the automobile after the automobile is parked in place, the driver stretches the hand to pick the wireless controller box, the rated load is input through the panel buttons, and discharging and loading are operated autonomously; and after the designated weight is reached, the discharging gate is automatically closed by the system, the drivers puts the controller box back and drives the loaded automobile to leave, and simpleness and rapidness are achieved.

Owner:TIANDI SCI & TECH CO LTD

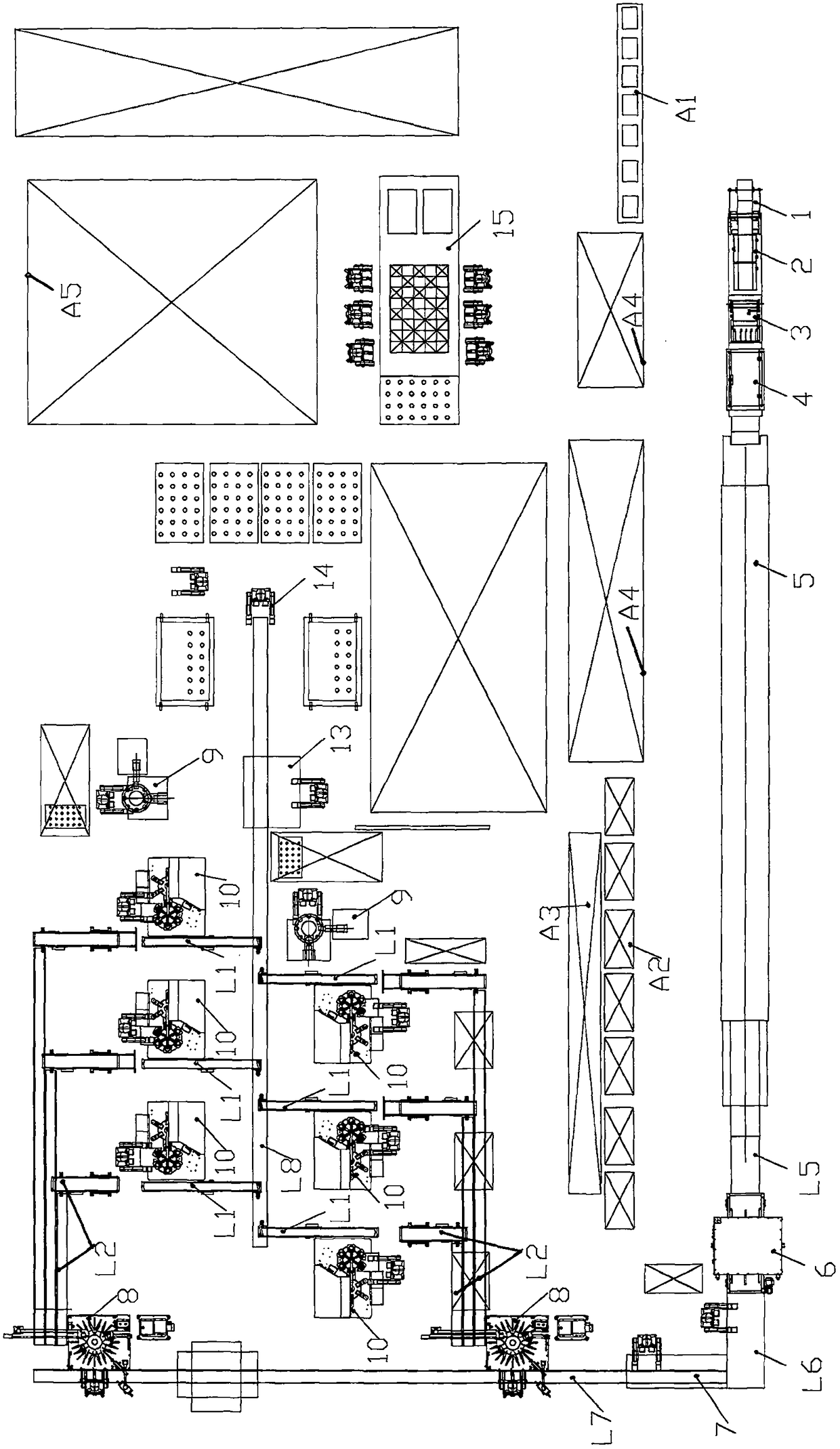

Automatic intelligent production line for environment-friendly filter element

PendingCN108749145AAvoid damageAchieving the goal of reducing staff and increasing efficiencyPaper/cardboard articlesProduction lineOrder form

The invention discloses an automatic intelligent production line for an environment-friendly filter element. The automatic intelligent production line comprises a filter paper slitting workstation, afilter paper heating workstation, a filter paper folding workstation and a filter paper shaping workstation, wherein a filter paper curing workstation (5), a filter paper cut-off workstation (6) and afilter paper one-piece stripping workstation (7) are sequentially mounted at a side edge of the filter paper shaping workstation; the filter paper one-piece stripping workstation is connected to a filter paper holding strip edge sealing workstation (8); a filter element end cap welding workstation (10) and a plastic end cap welding workstation (9) are mounted at a side edge of the filter paper holding strip edge sealing workstation; and a filter element checkout workstation (13) and a filter element off-line workstation (14) are sequentially mounted further. The automatic intelligent production line ensures that products do not fall onto the ground or will not be accumulated, synchronous on-line production of various products and production task arrangement are achieved at a time according to a customer order sequence, and the product quality and the production process control are improved.

Owner:ZHEJIANG UNIVERSE FILTER

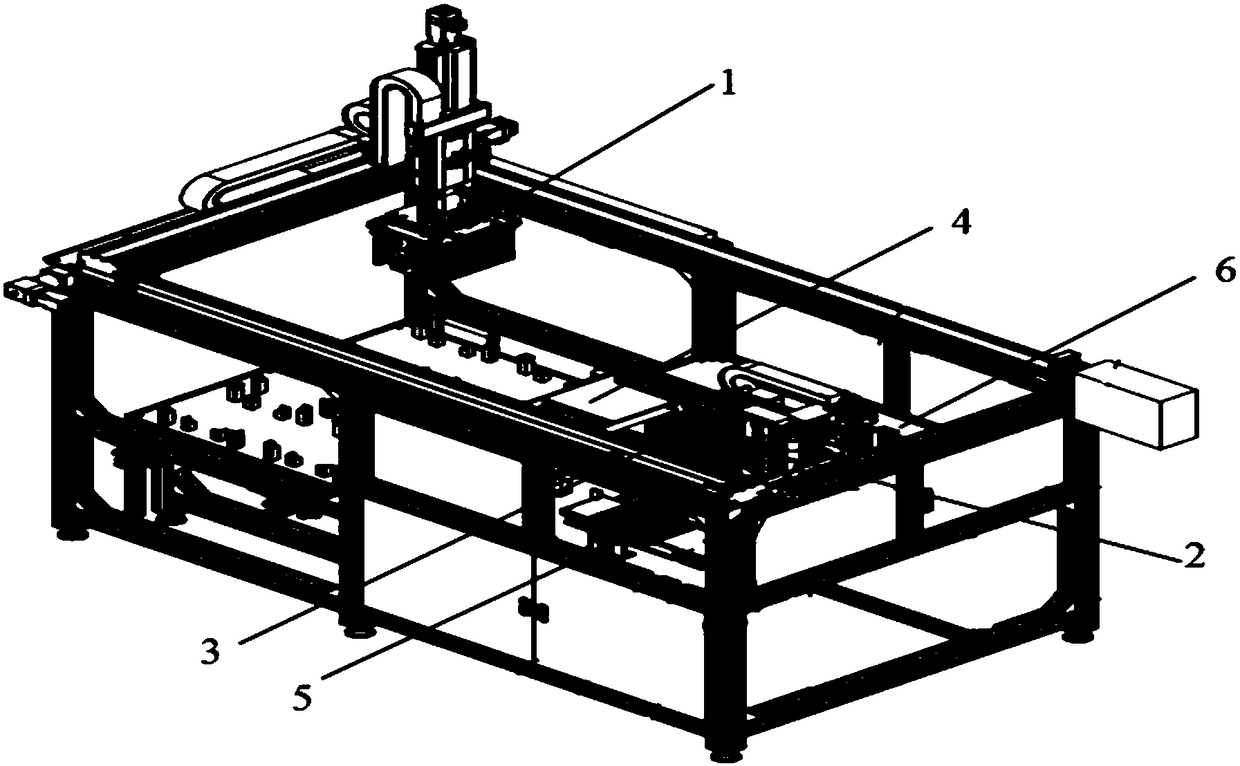

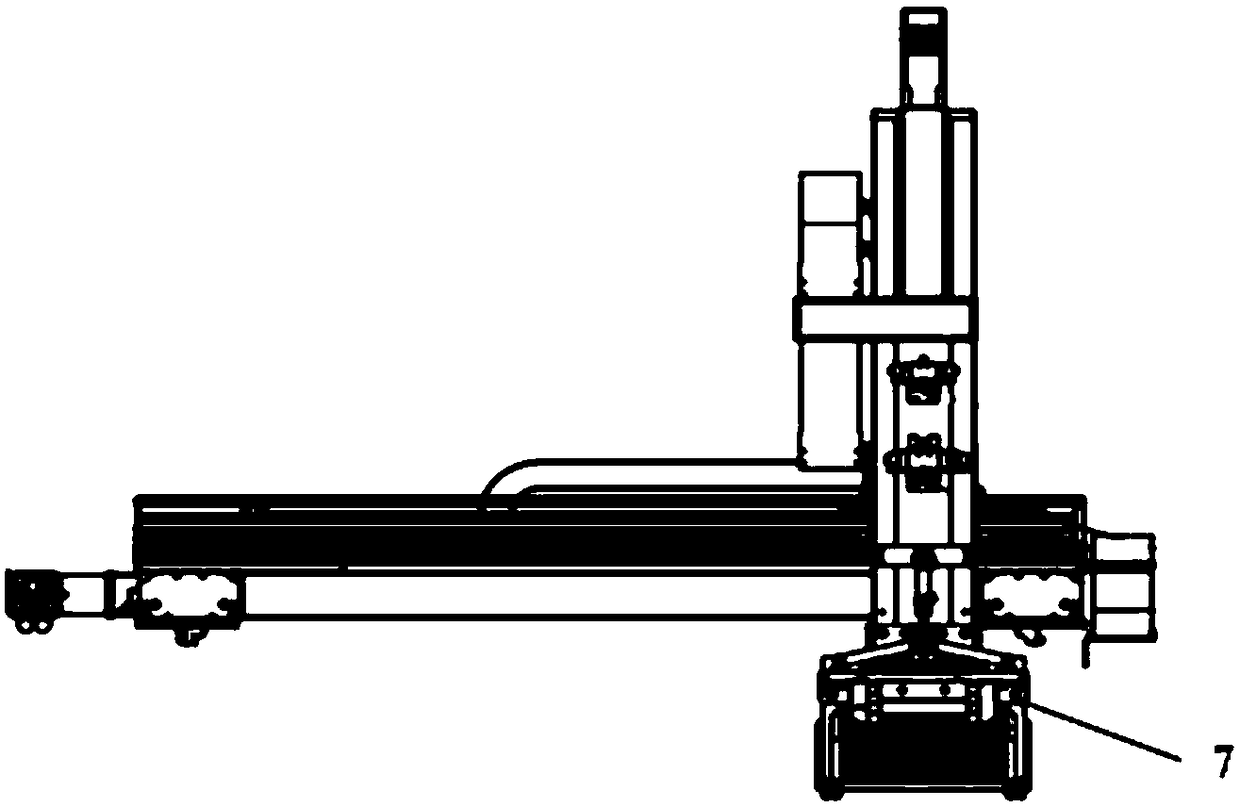

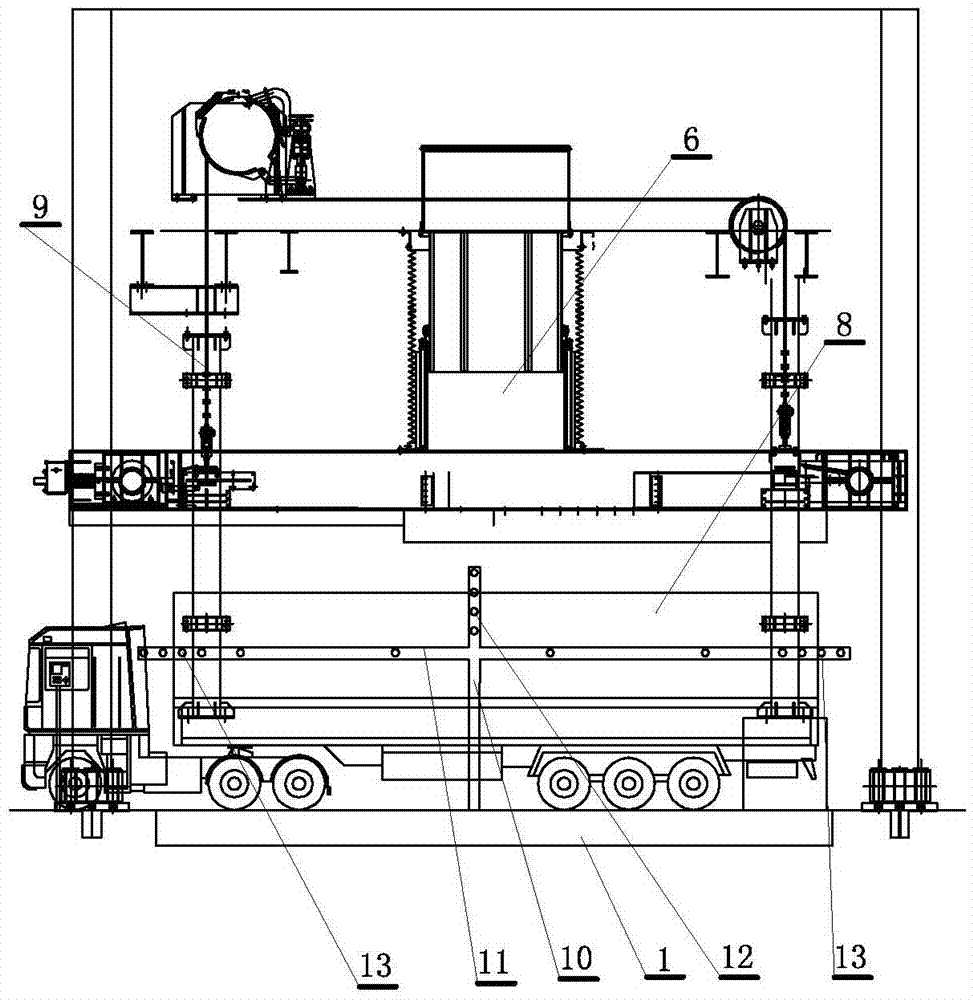

Automobile unloading automatic docking device

PendingCN108747270AAvoid buttAvoid draggingProgramme-controlled manipulatorMetal working apparatusRemote controlControl system

The invention discloses an automobile unloading automatic docking device and mainly relates to the field of tank wagon unloading devices. The device comprises a mechanical arm, a distance measuring system, an alignment system, a pipeline system and a control system. Automatic positioning and automatic docking of an oil unloading system and an oil unloading port position of a tank wagon are achieved. The device has the beneficial effects that production automation and remote control of a tank wagon unloading station are achieved, the automatic means is used for replacing simple and repeated work, and particularly in the dangerous chemical field, the purpose of reducing staff to improve efficiency can be achieved.

Owner:TIANJIN ZHENGFANG TECH DEV

Underground magnetic suspension robot system capable of automatically tracking fault of belt conveyor for coal mine

PendingCN109976353AReduce labor intensityEasy to detectPosition/course control in two dimensionsWireless controlCoal

The invention relates to an underground magnetic suspension robot system capable of automatically tracking the fault of a belt conveyor for a coal mine. The system comprises an electromagnetic guide rail, a magnetic suspension moving device, a wireless charging pile and a remote upper computer; the electromagnetic guide rail is fixed on a hanging bracket in a belt conveying roadway, and the magnetic suspension moving device is arranged on the electromagnetic guide rail; a video camera, a sensor, a wireless video receiving-transmitting module, a wireless control receiving-transmitting module, amagnetic suspension control module and a wireless charging module are arranged on the magnetic suspension moving device; the wireless charging pile is fixed at one end of the electromagnetic guide rail; an electromagnetic guide rail control module, a video receiving-transmitting module, a control receiving-transmitting module, a wireless charging control module, a PLC controller and an Ethernet interface module are arranged in the wireless charging pile; and the Ethernet interface module is connected with the remote upper computer via a network interface. The magnetic suspension robot systemprovided by the invention has the functions of automatic inspection, fault tracking, wireless charging and magnetic suspension automatic traveling, so that the labor intensity of workers is greatly reduced, and the detection effect is improved.

Owner:KAILUAN GRP

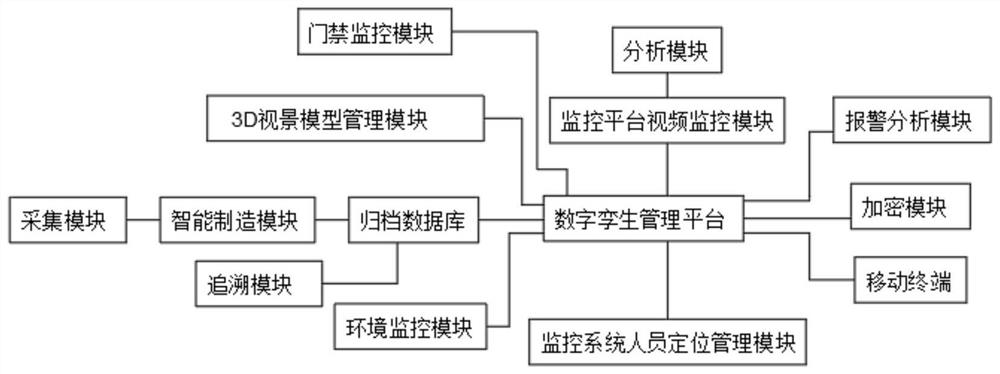

Digital twin monitoring system

PendingCN114609983AAchieving the goal of reducing staff and increasing efficiencyAvoid lostTotal factory controlProgramme total factory controlVideo monitoringModel management

Owner:数字孪生(无锡)技术有限公司

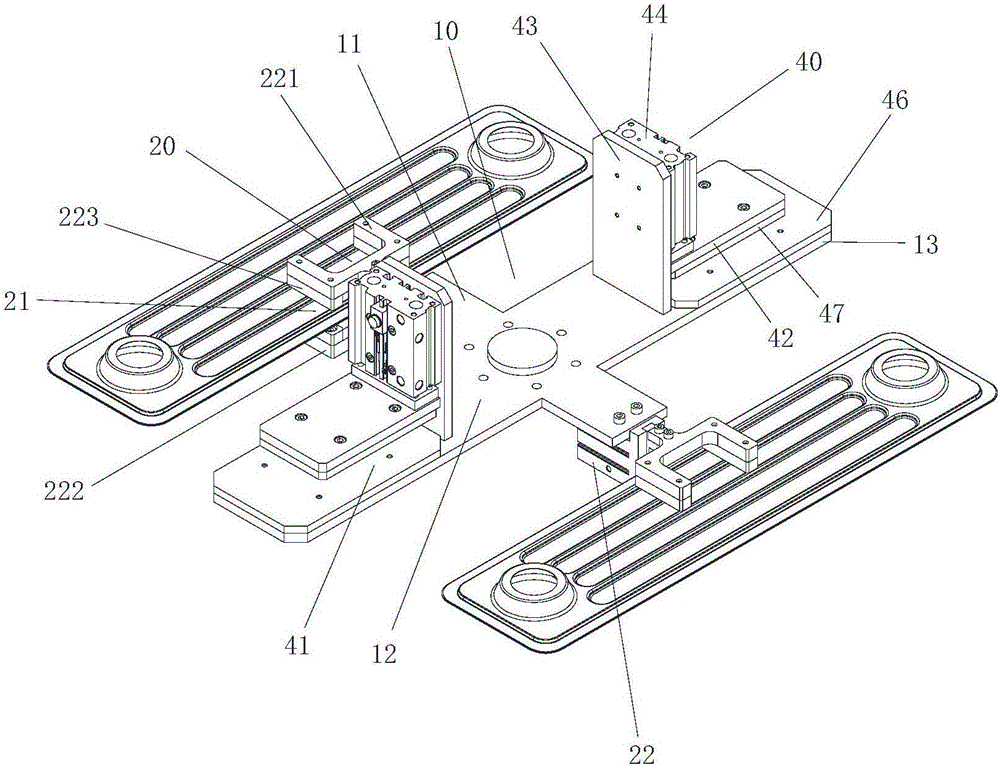

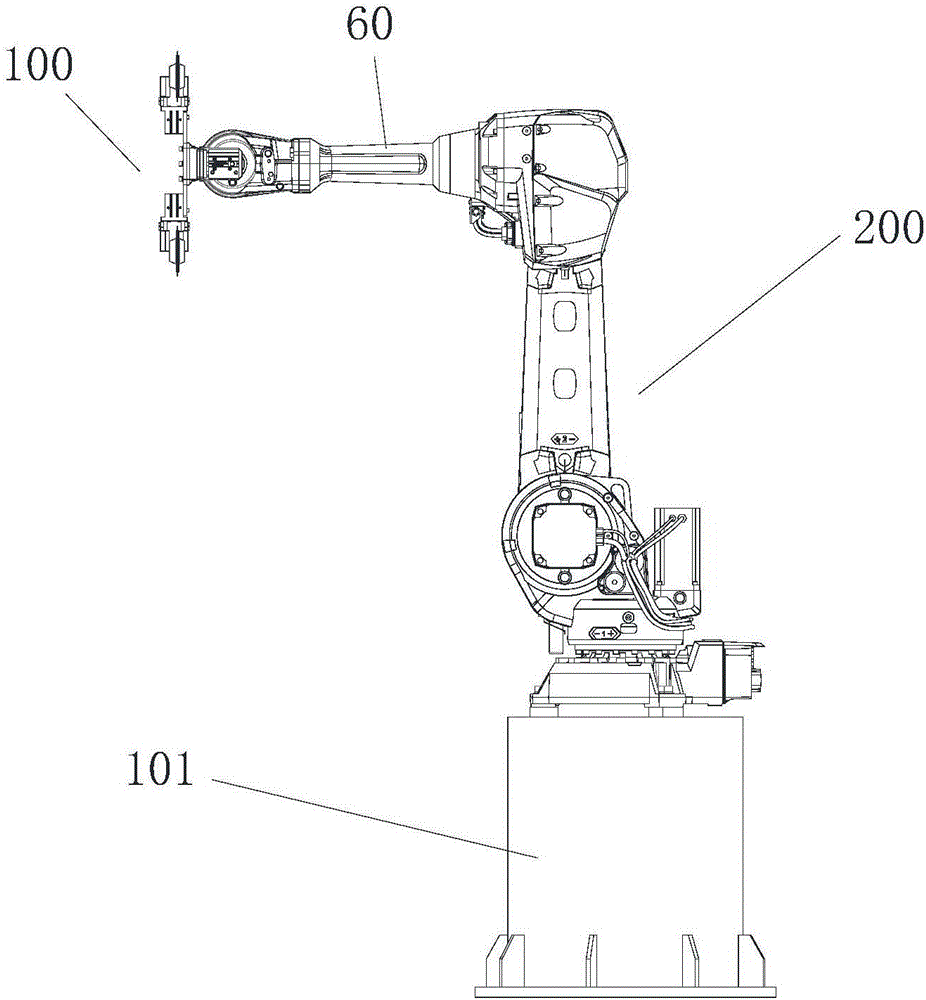

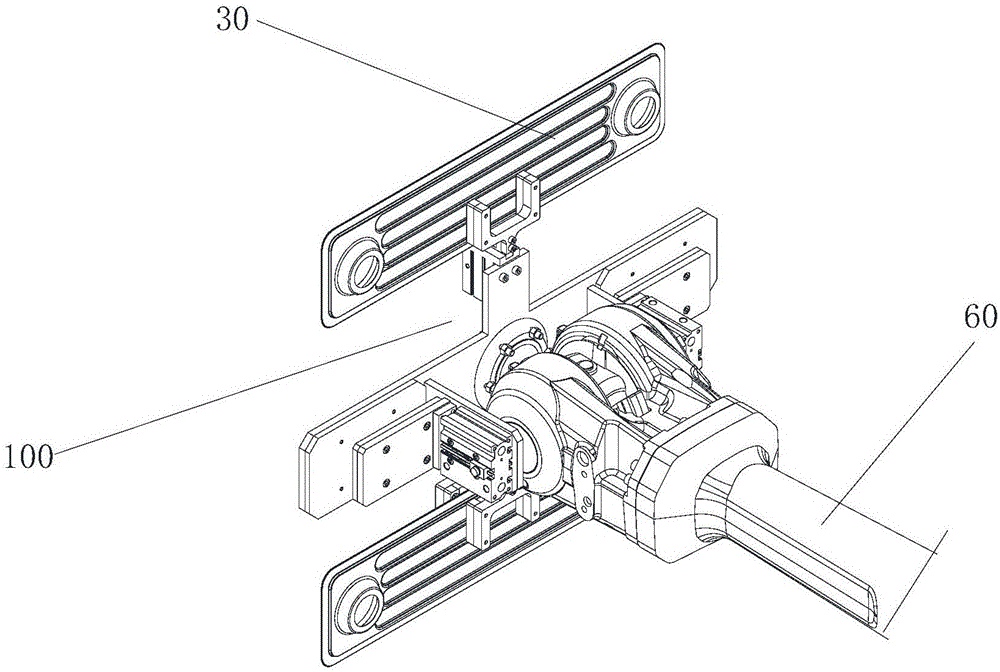

Oil heater clamping device, oil heater taking and placing robot and oil heater welding device

PendingCN106736220ARealize automatic loading and unloadingSolve the problem of low degree of processing automationProgramme-controlled manipulatorGripping headsThermodynamicsMechanical engineering

The invention provides an oil heater clamping device, an oil heater taking and placing robot and an oil heater welding device. The oil heater clamping device comprises a supporting frame, multiple oil heater piece clamping assemblies, and multiple oil heater body clamping assemblies. The multiple oil heater piece clamping assemblies are installed on the supporting frame at intervals, and each oil heater piece clamping assembly is provided with an oil heater piece clamping space used for clamping an oil heater piece. The oil heater body clamping assemblies are installed on the supporting frame and are provided with oil heater body clamping spaces used for clamping oil heater bodies. The oil heater clamping device solves the problem that the automation degree of oil heater machining is relatively low in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

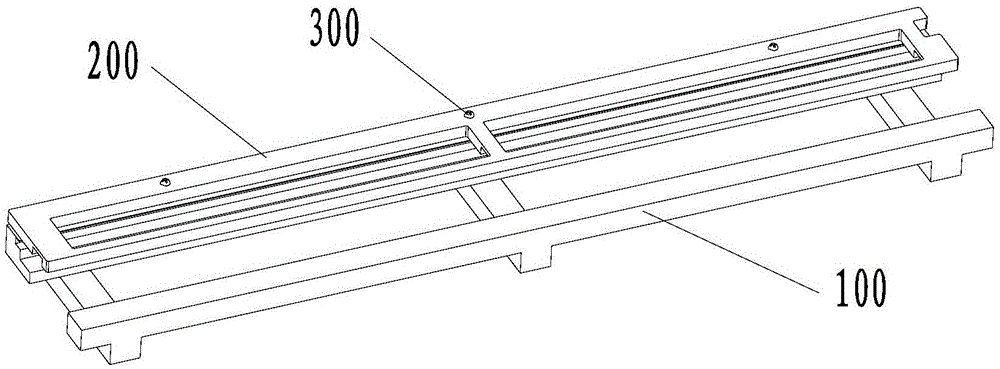

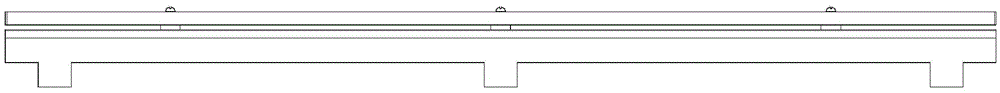

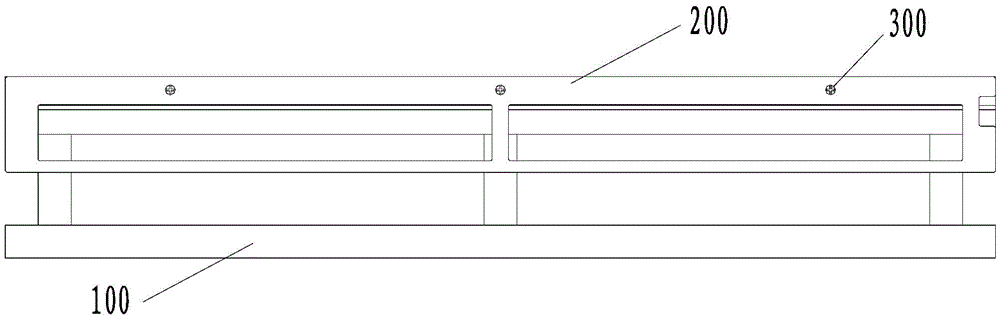

Tool for assembling display assembly

ActiveCN105458983AImplement fixed functionReduce labor intensityWork holdersMetal-working hand toolsDisplay deviceEngineering

The invention provides a tool for assembling a display assembly. The tool comprises a slide rail and a pressure plate, wherein a step is arranged on the slide rail; the step is configured to support the display assembly; the display assembly can slide on the step in a length direction of the step; one end of the pressure plate is arranged on the slide rail; the other end of the pressure plate is suspended; and the pressure plate is configured to limit the display assembly in an up-down direction. According to the tool for assembling the display assembly, the pressure plate is fitted with the slide rail, so that the fixing and sliding functions of the display assembly are realized; and the tool is simple in structure, is convenient and reliable to operate, improves the production efficiency, reduces labor intensity of staff, and avoids and quality and safety hidden danger, so that the purposes of downsizing staffs and improving efficiency are achieved.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

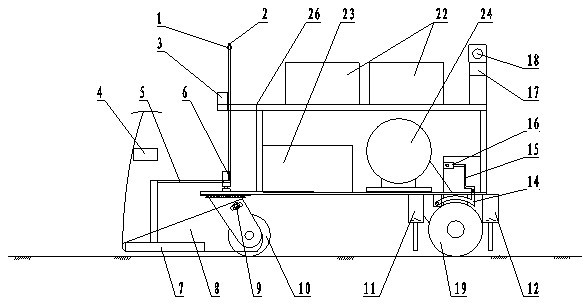

Self-propelled storage battery tractor

InactiveCN102320304ARealize unmanned drivingAchieving the goal of reducing staff and increasing efficiencyElectric locomotivesRailway transportVehicle frameControl system

The invention discloses a self-propelled storage battery tractor, which comprises a running system, a control system and a driving system. The running system comprises a frame, a handle, a screw rod, a direction connecting rod, a magnet, a magnet bracket, a universal wheel assembly, back wheels, a connecting rod and a brake block; the frame has a truss structure; the handle and the screw rod form a spiral drive pair; the lower end of the screw rod is connected with the back end of the direction connecting rod; the direction connecting rod is a lever mechanism; the magnet is positioned on the magnet bracket; the magnet bracket is fixedly arranged on a universal wheel shaft; the universal wheel assembly is mounted at the middle position of the front part under the frame; the right side wheel of the back wheels is fixedly connected with a driving shaft; the left side wheel of the back wheels is movably connected with the driving shaft through a bearing; one end of the connecting rod is connected with a component of a control part; the other end of the connecting rod is connected with the brake block; and the front end of the brake block is hinged with the frame and is placed above the back wheels on two sides. By using an automatic material conveying system provided by the invention, the labor intensity of a worker can be decreased, and the work efficiency is improved.

Owner:GREAT WALL MOTOR CO LTD

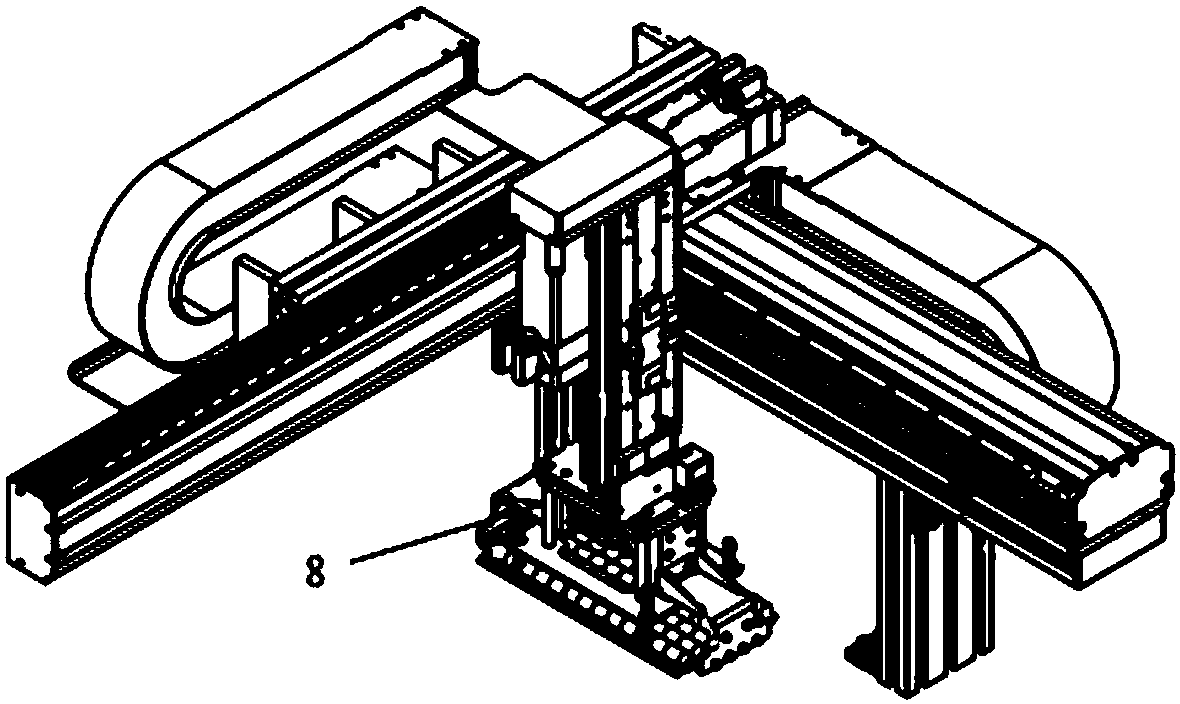

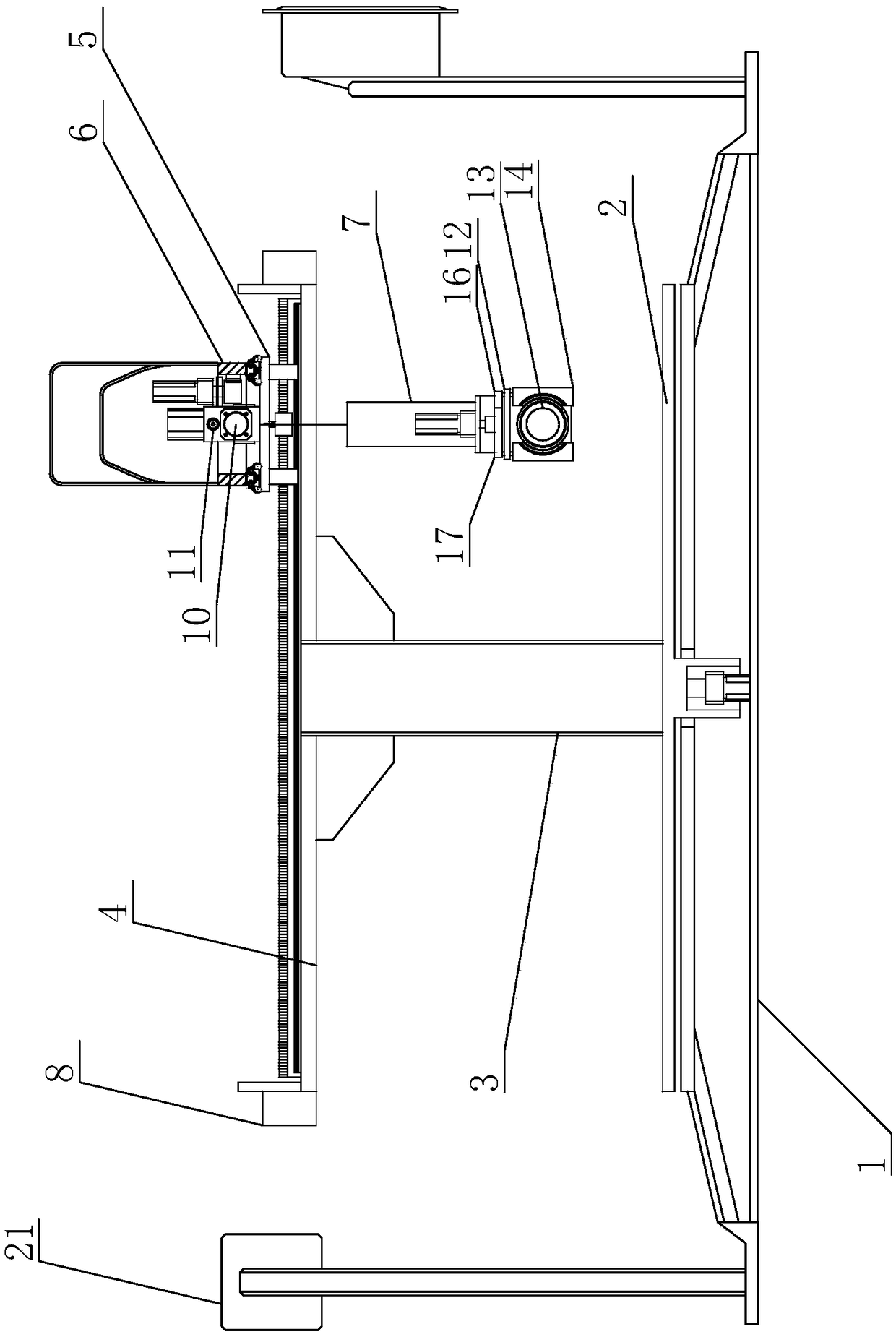

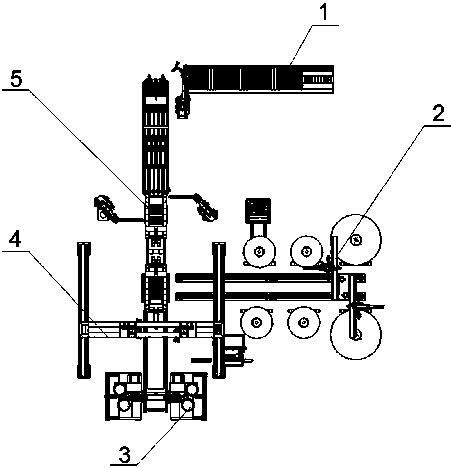

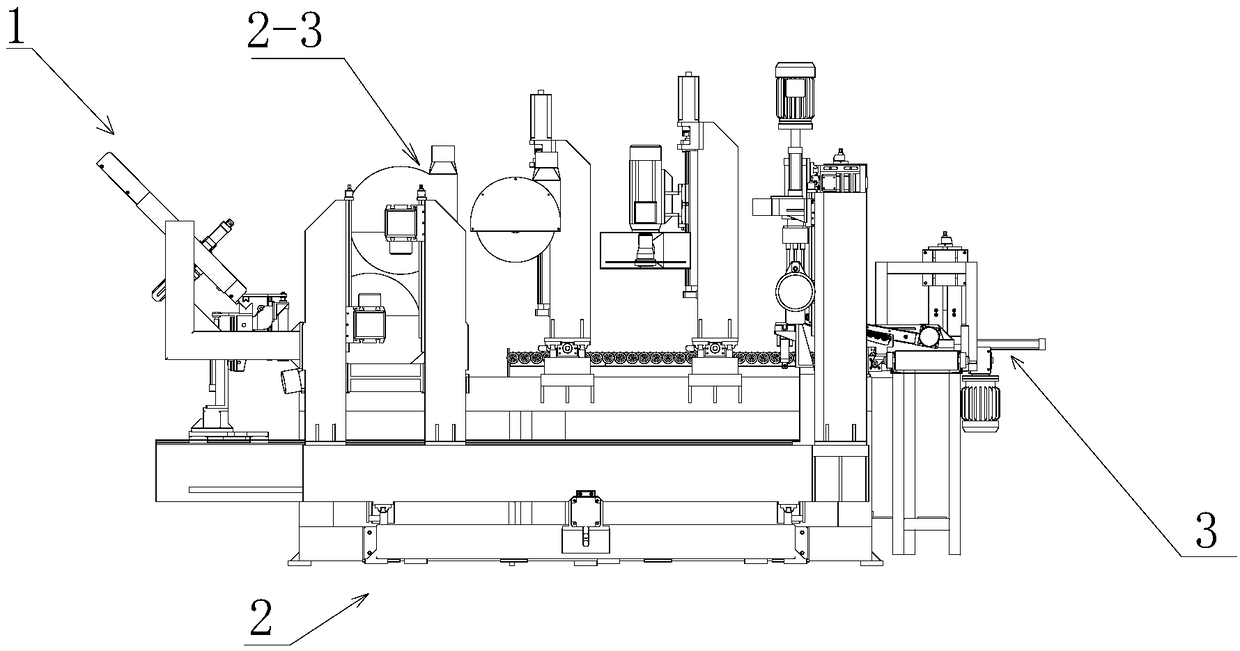

Automatic assembling system for cable tray

PendingCN110238650ALabor savingFast assemblyAssembly machinesMetal working apparatusCable trayEngineering

The invention relates to an automatic assembling system for a cable tray. The automatic assembling system comprises a rack and a control system, wherein the rack is provided with a core plate feeding station (1), a disc feeding station (2) and a core plate forming station (5), the core plate feeding station (1) comprises a core plate conveyor belt (12) and a core plate extraction robot (13) arranged on one side of the core plate conveyor belt, the disc feeding station (2) comprises a disc moving device, a disc feeding rack (22), and a disc overturning and positioning claw (23) arranged on the disc moving device, the two sides of the core plate forming station (5) are correspondingly connected with the core plate conveying belt (12) and the disc moving device, a screw feeding station (4) is arranged at the lower end of the core plate forming station (5), and a wire coil fastening station (3) is arranged at the lower end of the screw feeding station (4). The automatic assembling system for the cable tray has the beneficial effects that manpower is saved, the assembly speed is fast, the efficiency is high, and the customers is helped to achieve the purpose of reducing staff and improving efficiency.

Owner:CHENGDU JIUXI ROBOT TECH CO LTD

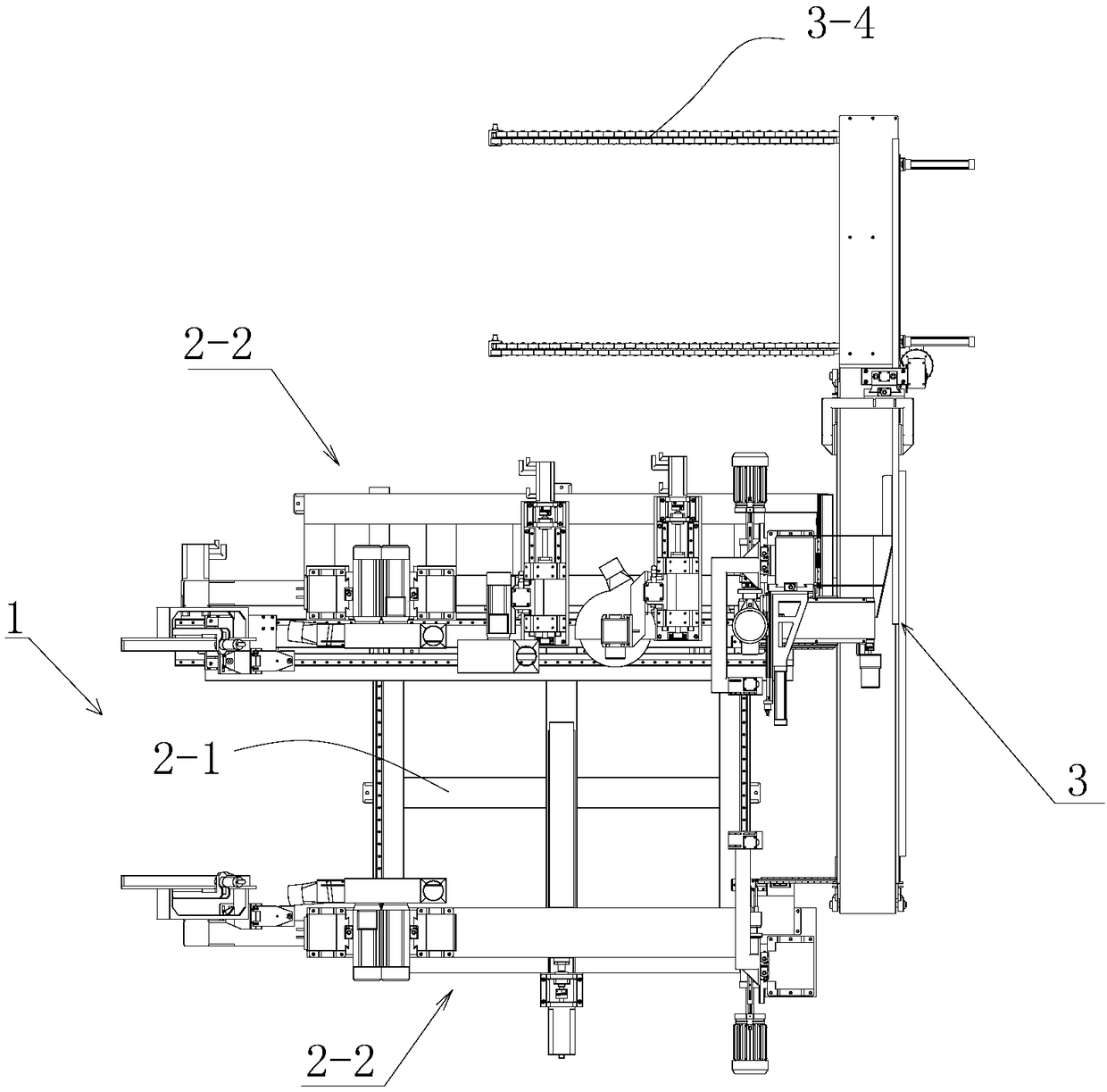

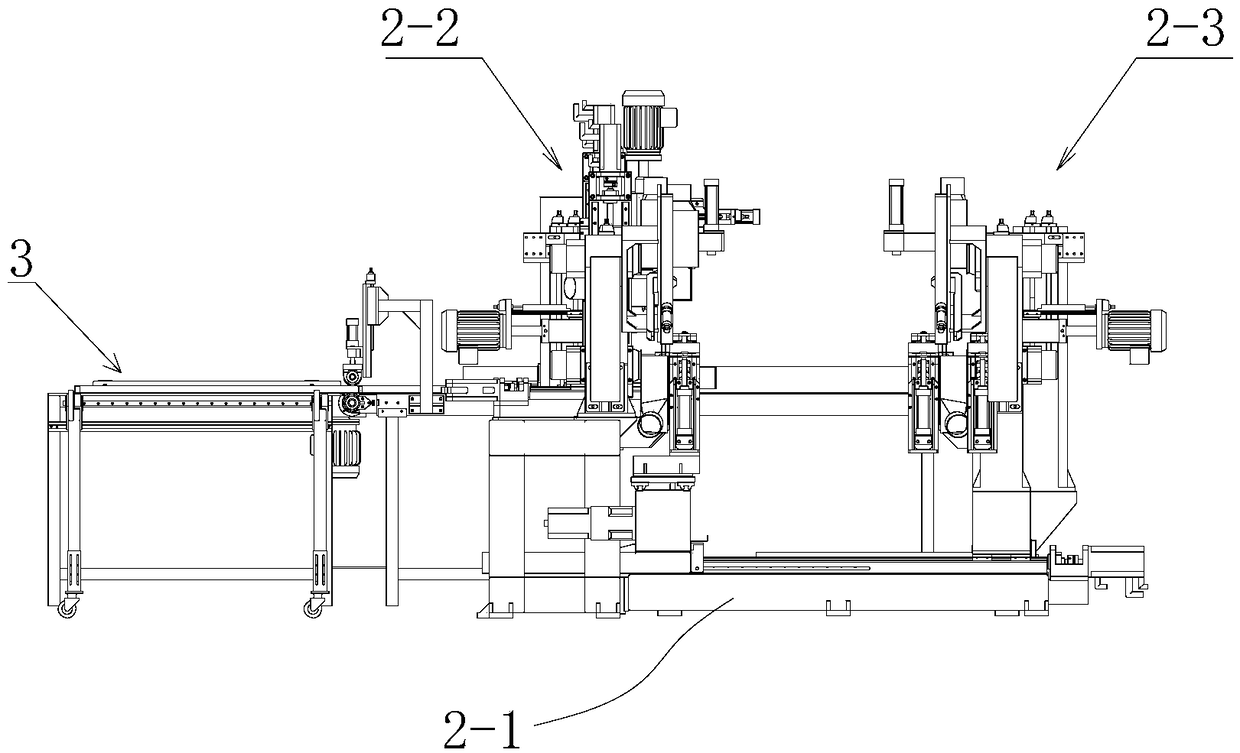

A furniture table leg solid wood parts dual -end -end -of -cut corner punch punching machine and processing method

ActiveCN106166766BCan be integratedIncrease productivityStationary drilling machinesFeeding devicesSolid woodEngineering

The invention relates to a double-end fixed length corner cutting and perforating machine and method for furniture table leg solid wood components. The double-end fixed length corner cutting and perforating machine comprises a feeding bin, a machine body and a finished material conveying mechanism; the finished material conveying mechanism is mounted at the discharging end of the machine body; a fixed work station is mounted on a base of the machine body; a movable work station is mounted on the other side; a linear sliding rail is mounted on the base, the movable work station is mounted on the linear sliding rail, and a servo driving device is mounted on the base; a fixed length saw set, a vertical corner cutting saw set, a fixed horizontal corner cutting saw set, a horizontal drill machining set and a vertical drill machining set are mounted on a fixed workbench; a movable fixed length saw set is mounted on a movable workbench in the material feeding direction; a movable horizontal drill machining set is mounted at the position, corresponding to the fixed horizontal drill machining set, of the movable work station; a clamping conveying device is further arranged. Compared with traditional single machining, production efficiency is greatly improved, labor intensity is reduced, labor force is reduced, and the aims of downsizing staffs and improving efficiency are achieved.

Owner:美克数创赣州家居智造有限公司 +2

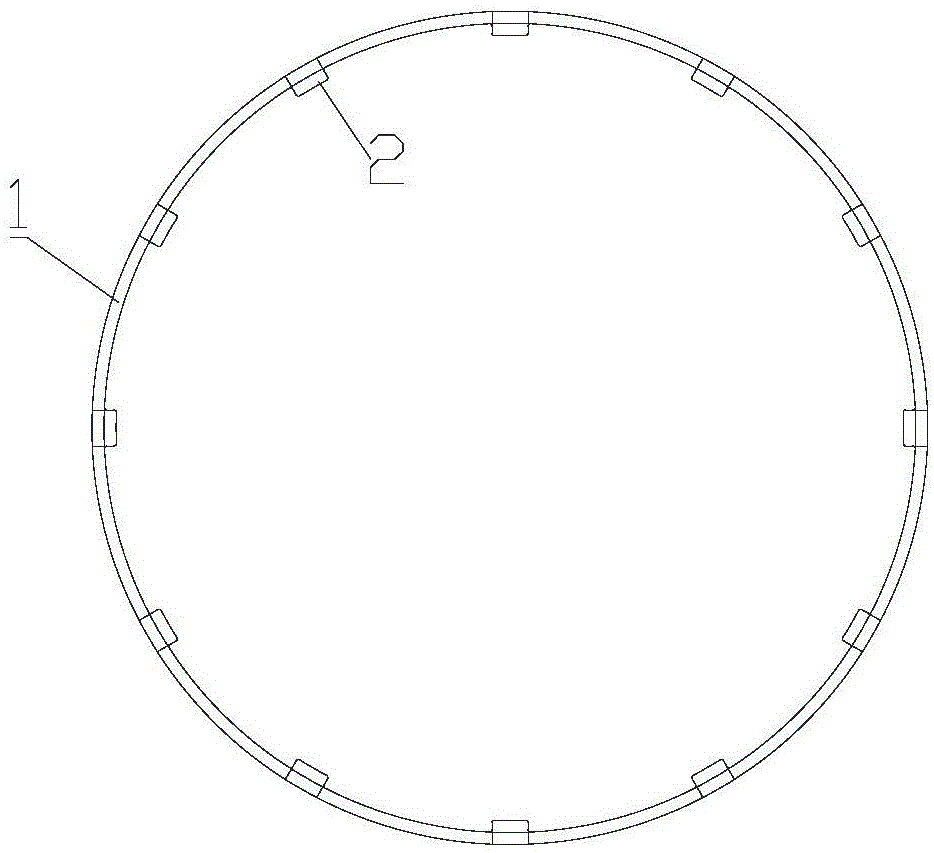

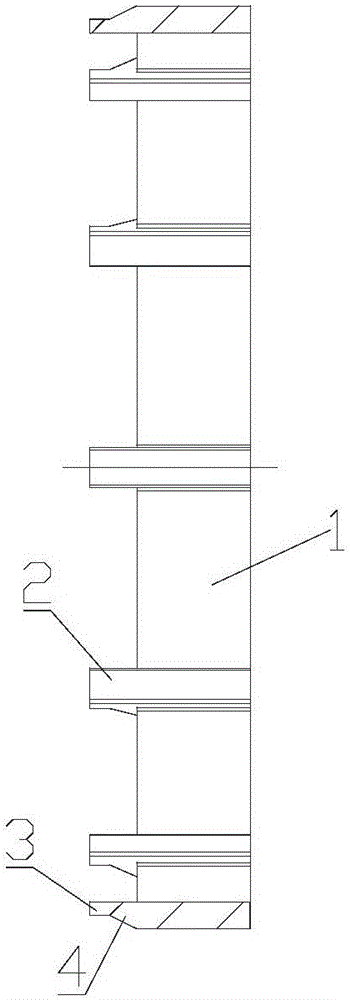

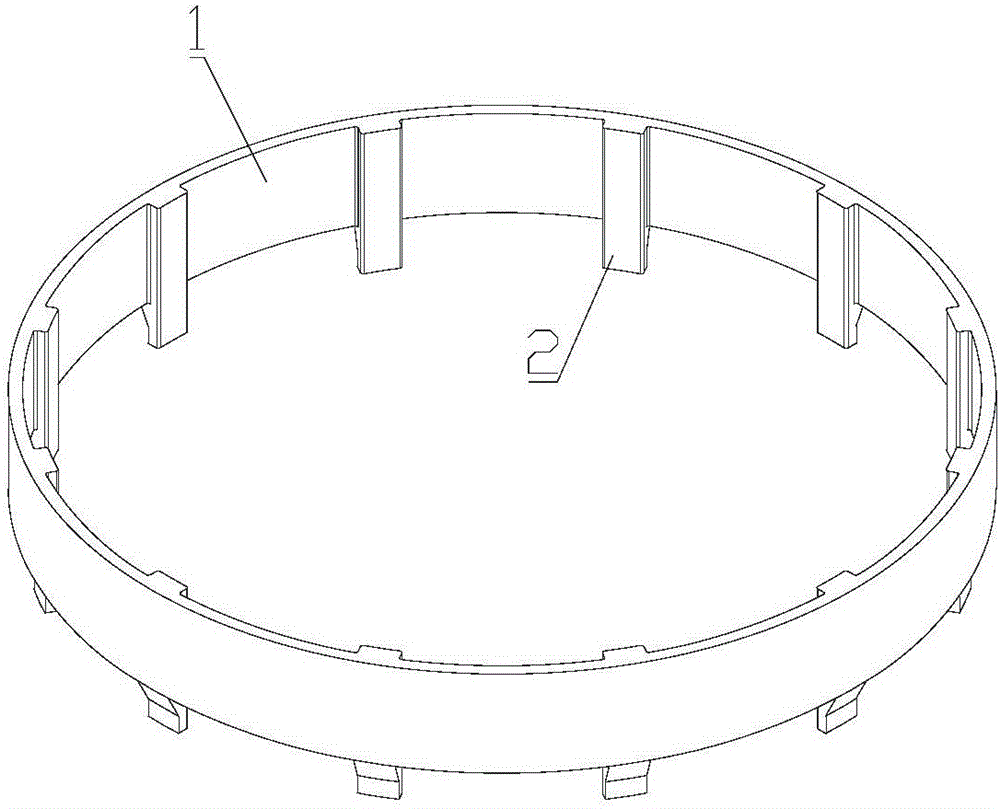

Stator retainer, motor stator and motor stator injection molding method

ActiveCN106160276APrevent injection displacementAvoid displacementMagnetic circuit stationary partsManufacturing dynamo-electric machinesCopperInjection molding machine

The invention discloses a stator retainer, a motor stator and a motor stator injection molding method. The stator retainer comprises a ring body which is matched with an internal diameter of a winding of a stator to be injected. Because the ring body is in contact with an inner wall of the winding during the injection molding, the injection molding shifting and deformation abnormities of the winding in the injection molding process can be avoided, and the copper exposed problem of injection molding stator can be avoided too. Thus the stator can be finally assembled in one flow production, and the purpose of downsizing for efficiency is reached.

Owner:GREE ELECTRIC APPLIANCES INC +1

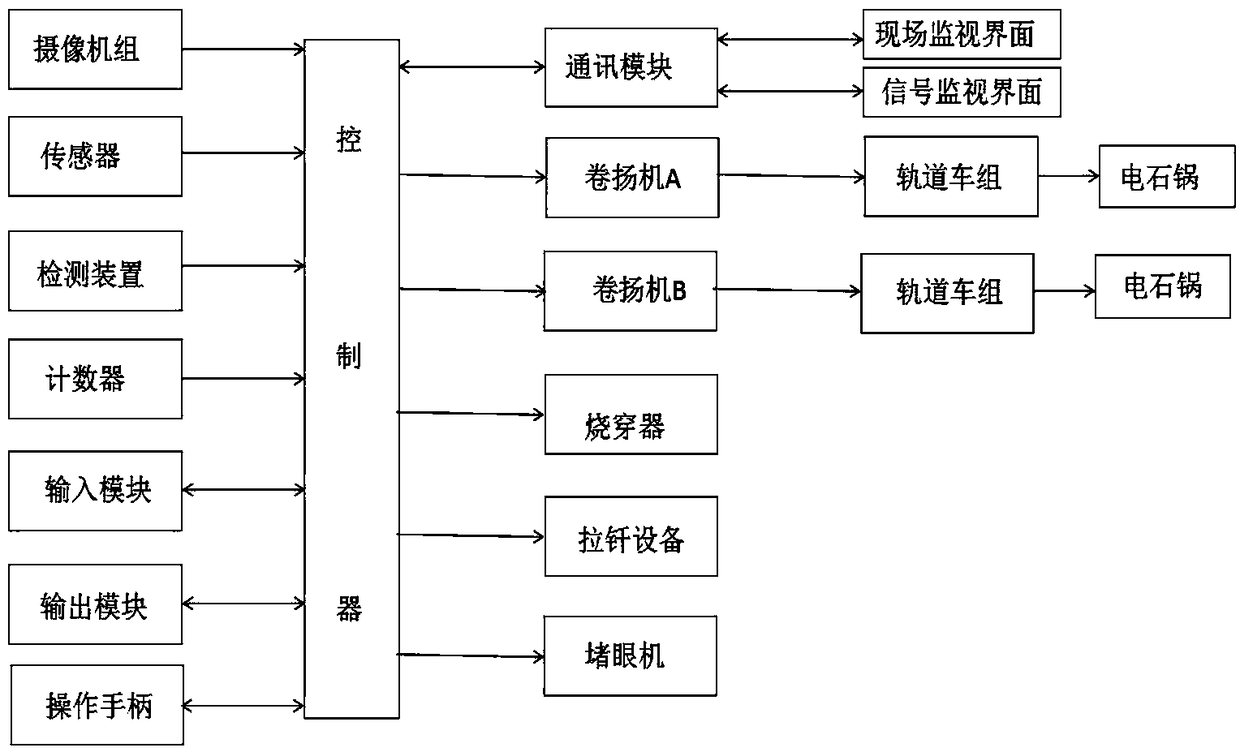

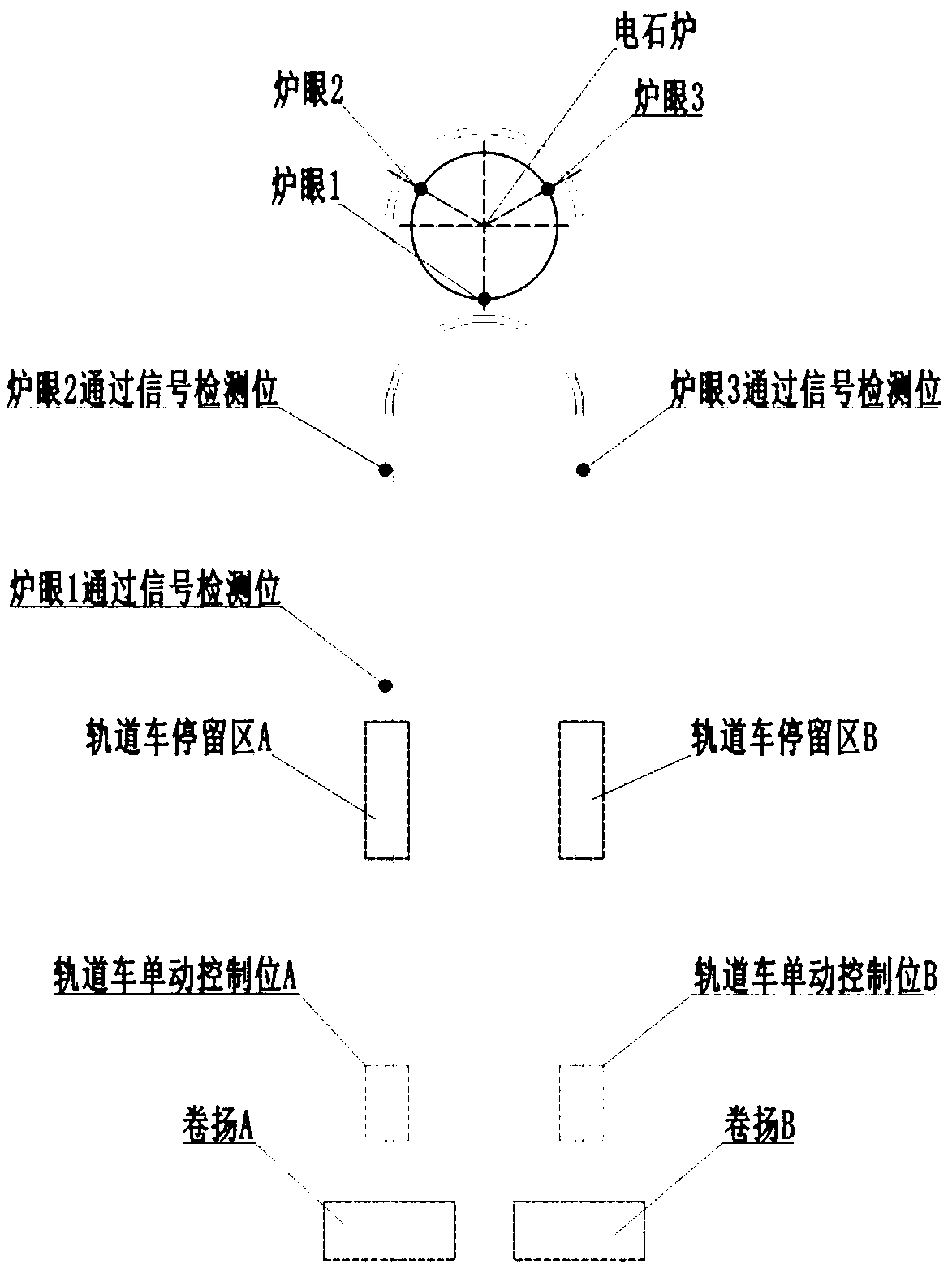

Furnace discharging control system for calcium carbide furnace remote control and control method of furnace discharging control system

ActiveCN109059553APrecise positioning of eye-burning operationsReduce in quantityCharge manipulationCalcium carbideSystems designRemote control

The invention provides a furnace discharging control system for calcium carbide furnace remote control and a control method of the furnace discharging control system. The control system comprises a controller, a wireless communication module and a display module. The display module comprises a field monitoring interface and a signal monitoring interface. The controller collects running states andfeedback signals of various executing mechanisms and conduct displaying on the field monitoring interface and the signal monitoring interface of the display module. The input end of the controller isconnected with a sensor, a camera, a detecting device and a counter, wherein the sensor is used for monitoring the walking positions of track cars, a winch unit, a bottom trolley and a hole stopping machine in real time, the camera is used for conducting video collection on the work face of a furnace discharging system, the detecting device is used for detecting the furnace discharging work statesignals, and the counter is used for counting the frequency that the track cars pass through a furnace hole. The system is reasonable in design and convenient to achieve, the method steps are simple,the purposes of downsizing staffs and improving efficiency are achieved, the safety coefficient is improved, practicability is high, the usage effect is good, and usage and popularization are convenient.

Owner:DALAD BANNER BRANCH OF INNER MONGOLIA YILI ENERGYCO

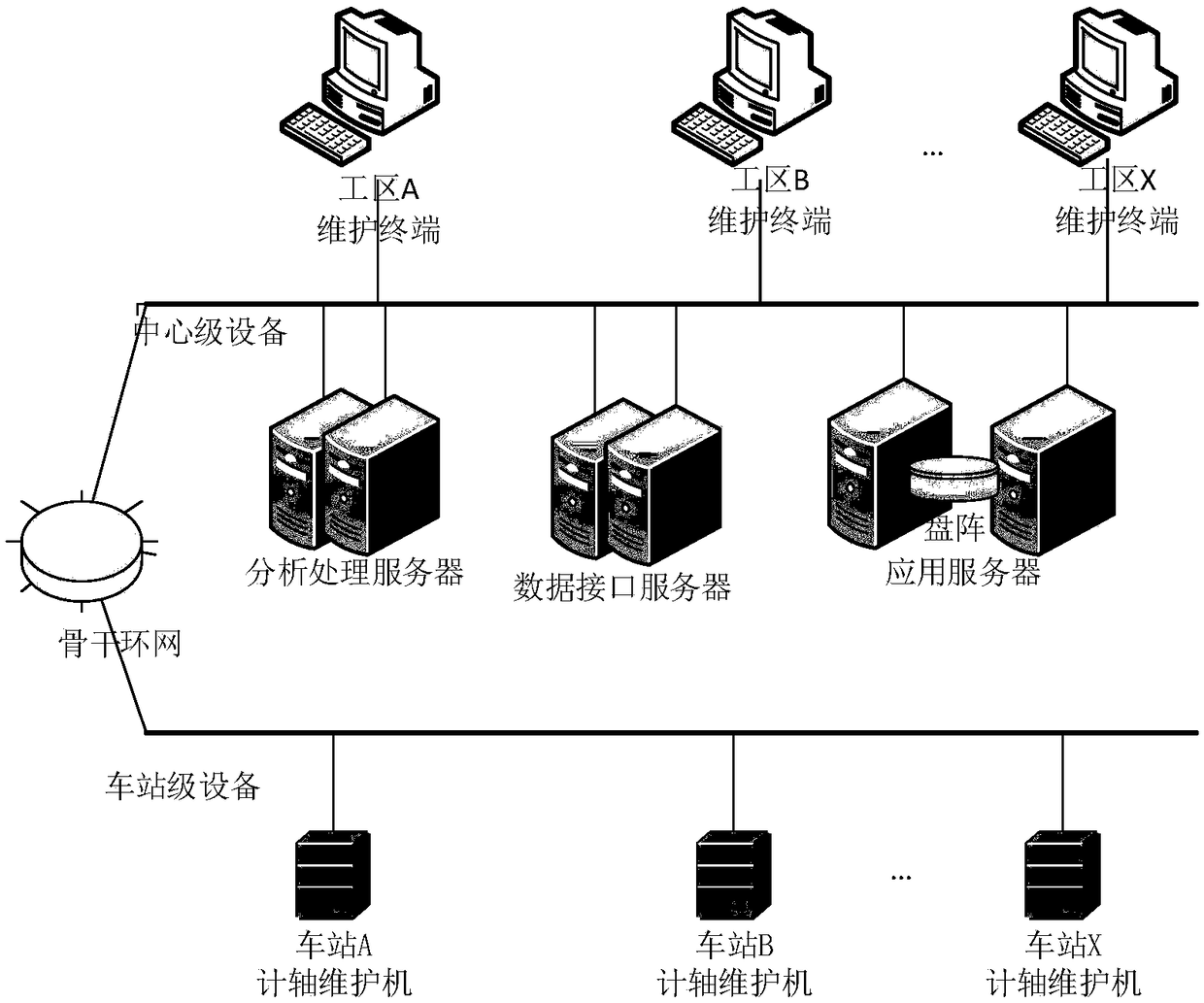

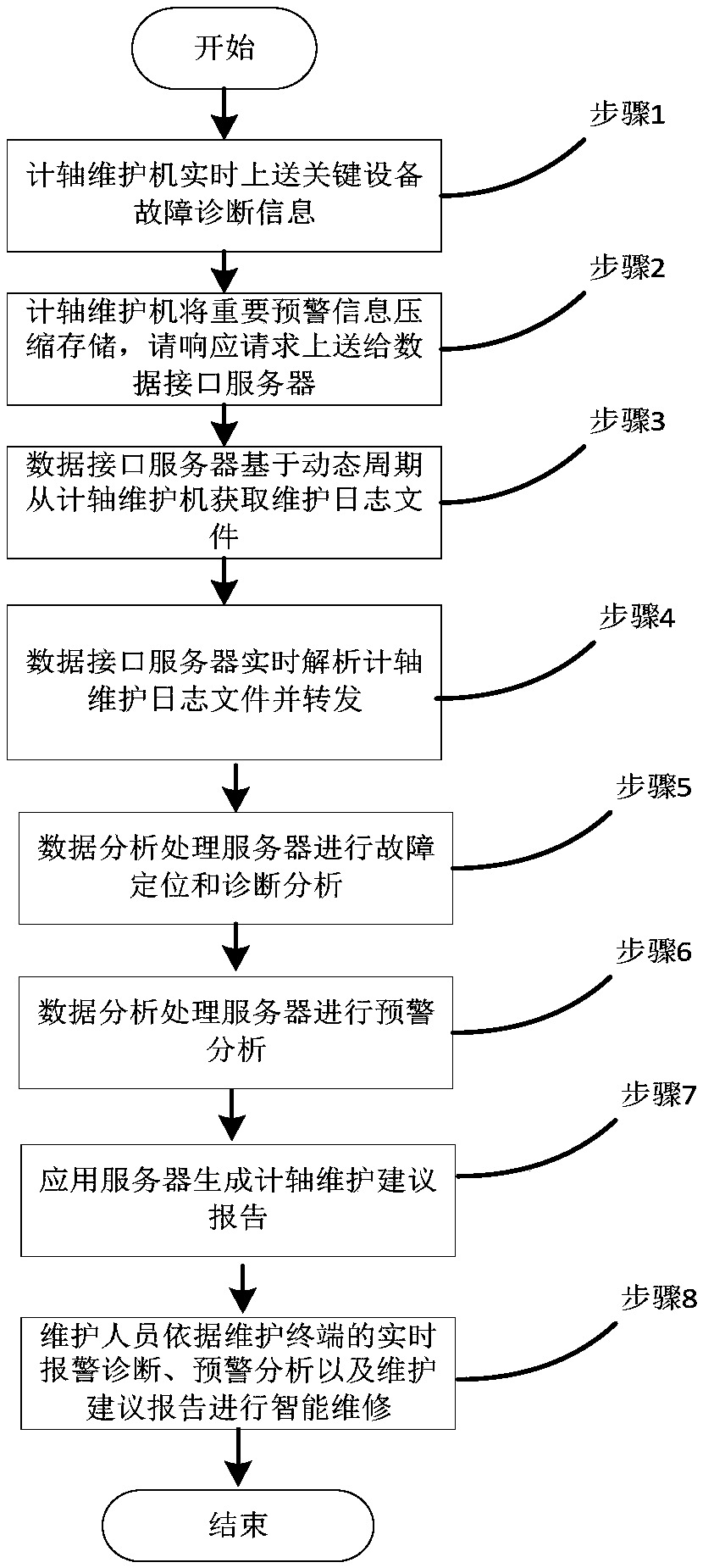

Intelligent maintenance system and method for urban railway transit axle counter subsystem

InactiveCN108958072AImprove fault diagnosis efficiencyCompression failure delayMeasurement devicesVehicle route interaction devicesApplication serverDisk array

The invention relates to an intelligent maintenance system and method for an urban railway transit axle counter subsystem. The intelligent maintenance system for an urban railway transit axle countersubsystem includes an axle counter maintenance machine, a data interface server, an analysis processing server, an application server and a memory disk array, a maintenance terminal and a backbone ring network, wherein the axle counter maintenance machine, the data interface server, the analysis processing server, the application server and the memory disk array, and the maintenance terminal are mutually connected through the backbone ring network. Compared with the prior art, the intelligent maintenance system and method for an urban railway transit axle counter subsystem has the advantages of high automation degree, high security, high intelligence, libration of maintenance manpower, implementation of increasing efficiency and downsizing staff and the like.

Owner:CASCO SIGNAL

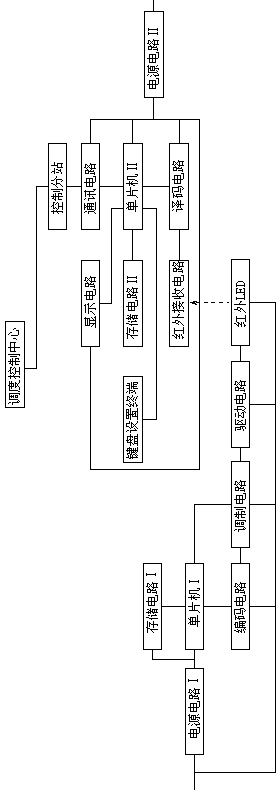

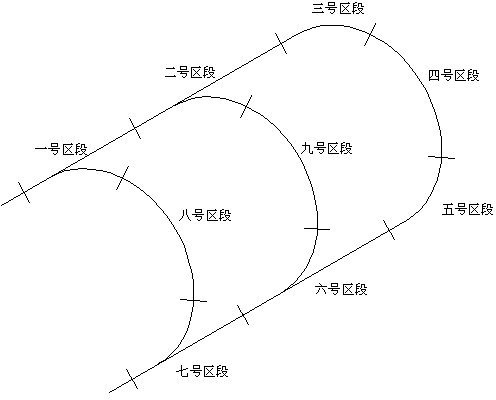

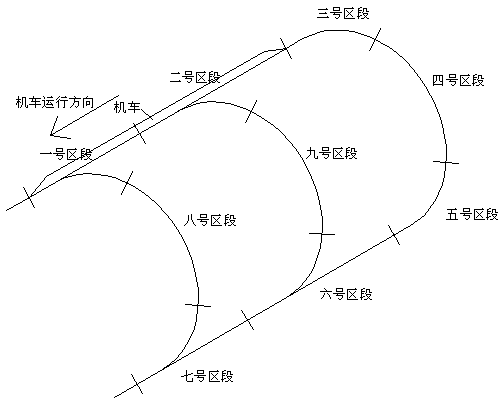

Moving-block technology-based method for dividing underground narrow-gauge track block section

ActiveCN104141509AExtended shipping timeIncrease flexibilityMining devicesUnderground transportEngineeringHeadstock

The invention relates to a moving-block technology-based method for dividing an underground narrow-gauge track block section. The method comprises the following steps of dividing all tracks in an underground station of a mine into a plurality of basic track section units in advance; enabling an infrared positioning transmitter on the outer side of a headstock of a locomotive to emit infrared data with a locomotive number coded message in real time; after infrared positioning receivers arranged on two sides of an underground roadway receive the infrared data with the locomotive number coded message, enabling the infrared positioning receivers to feed the data back to a dispatcher control center; enabling the dispatcher control center to judge the state of a track section in which the locomotive runs according to the position of the locomotive and to automatically perform locking and unlocking control over the track to dynamically divide the track block section. The method replaces the traditional method for dividing an underground narrow-gauge track fixed section, the locomotive dispatching flexibility and the mine transporting efficiency of the underground locomotive are improved, the maintenance and the loss of equipment are reduced, the method is subjected to small influence of environmental factors and the underground safety transportation is guaranteed.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

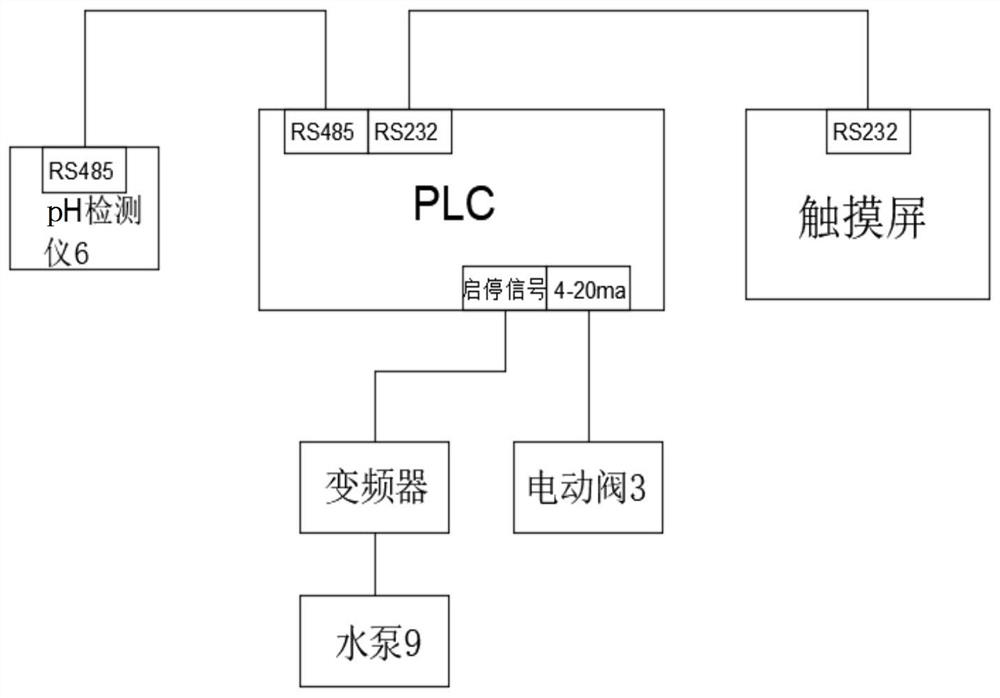

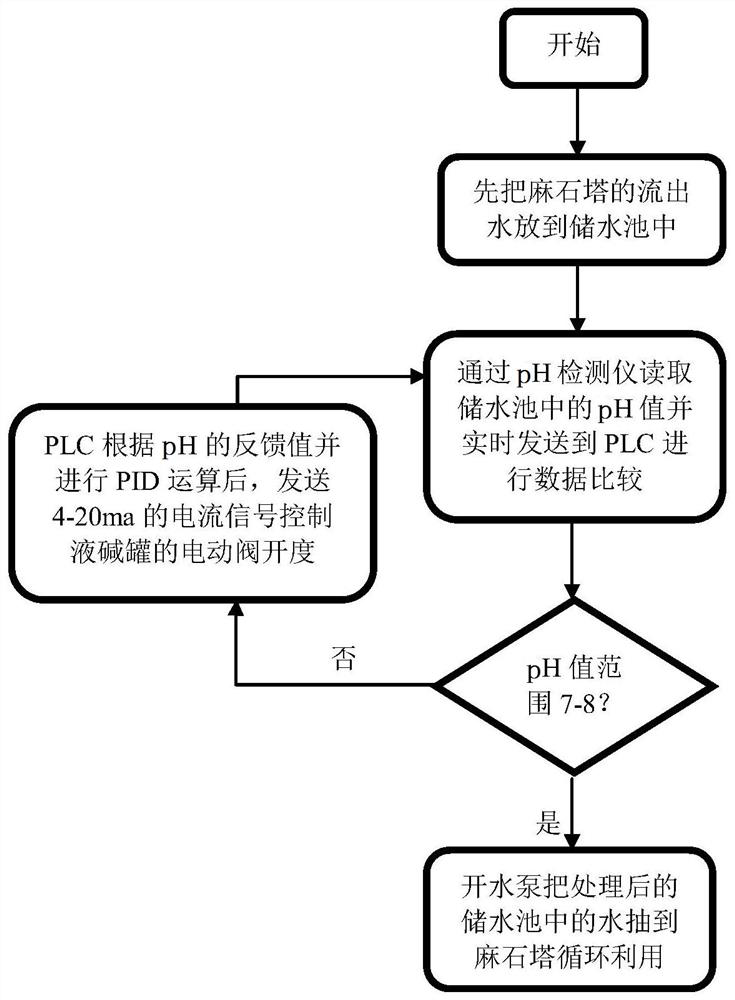

Ceramic granite tower circulating water treatment system, circuit and pH value control method

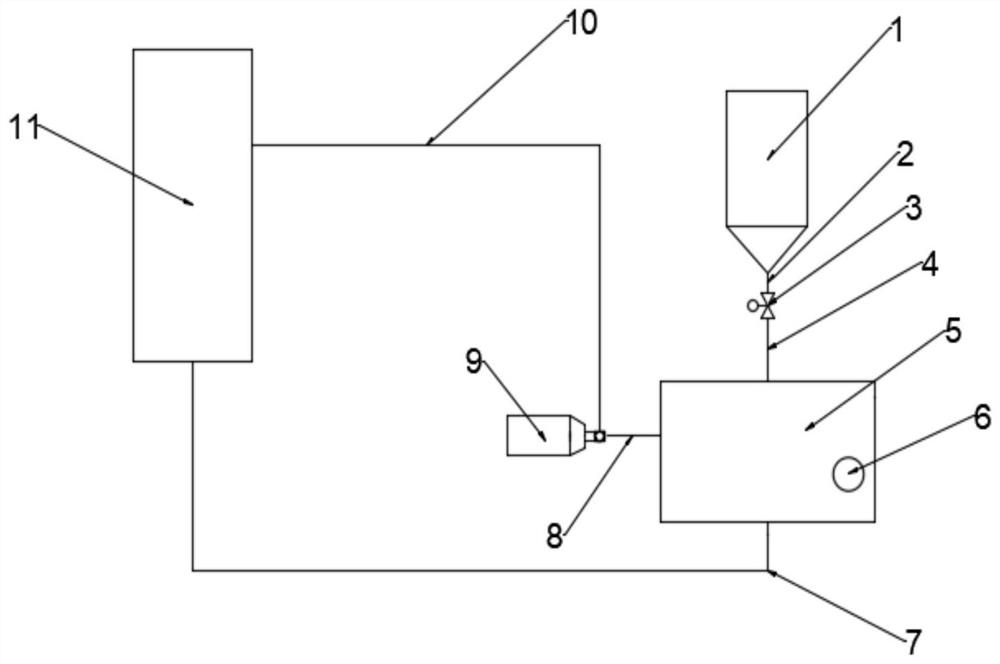

InactiveCN112919606AImprove desulfurization effectEfficient and convenient processingWater treatment parameter controlControlling ratio of multiple fluid flowsWater storage tankClosed loop

The invention relates to a ceramic granite tower circulating water treatment system, a circuit and a pH value control method. The treatment system comprises a closed loop consisting of a granite tower, a water storage tank with a built-in pH detector, a water pump and the granite tower which are sequentially communicated, an electric valve and a liquid caustic soda storage tank which are sequentially communicated with another pipeline of the water storage tank, and an electric control circuit. The control method comprises the following steps: (1) enabling water in the granite tower to flow into the water storage tank; (2) reading the pH value in the water storage tank through the pH detector, and sending the pH value to a PLC (Programmable Logic Controller) in real time for data comparison; (3) judging whether the pH value is in a set value range or not, if not, sending a current signal to control the opening degree of an electric valve of the liquid caustic soda tank by the PLC controller according to a pH feedback value and after PID operation, and returning; and if yes, entering the next step; and (4) starting the water pump and pumping the treated water in the water storage tank to the granite tower for cyclic utilization.

Owner:GUANGDONG JIA MEI CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com