Stator retainer, motor stator and motor stator injection molding method

A retainer and stator technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as stator copper exposure that cannot be injected into the stator, and achieve the effect of preventing injection molding from shifting and avoiding copper exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

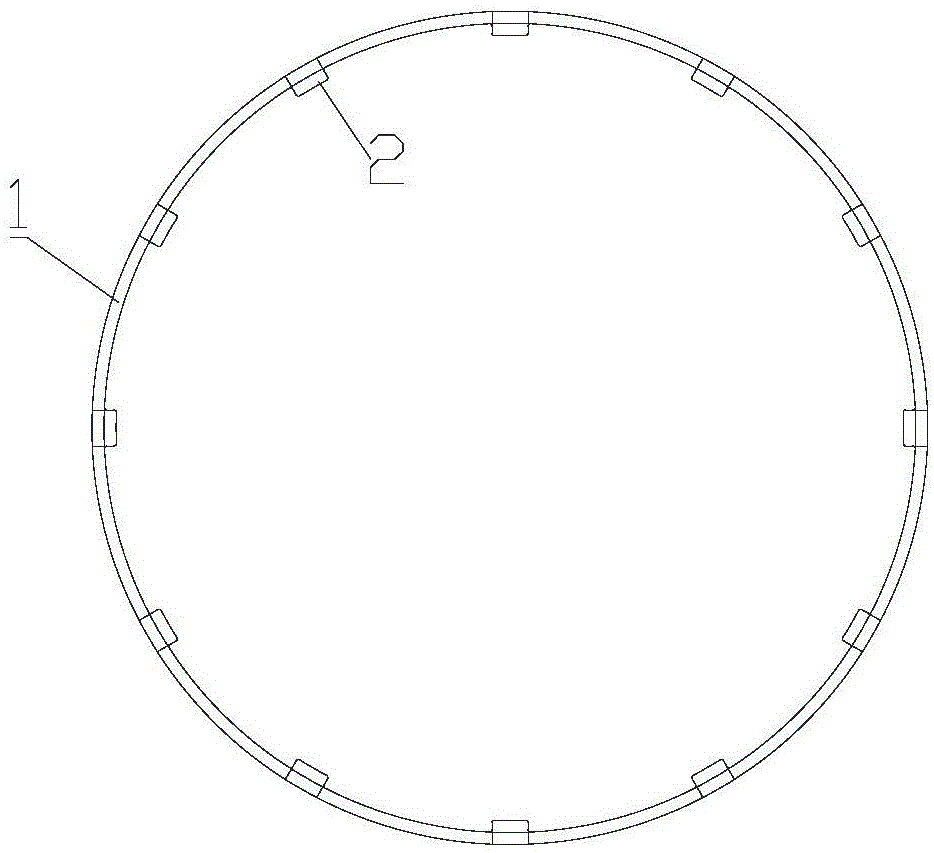

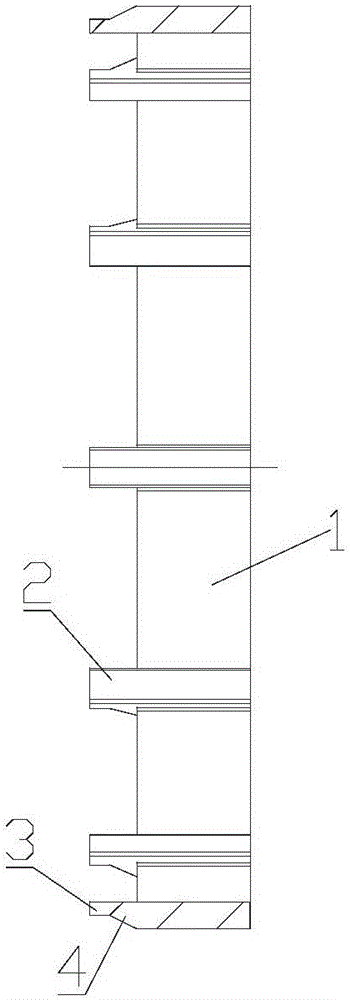

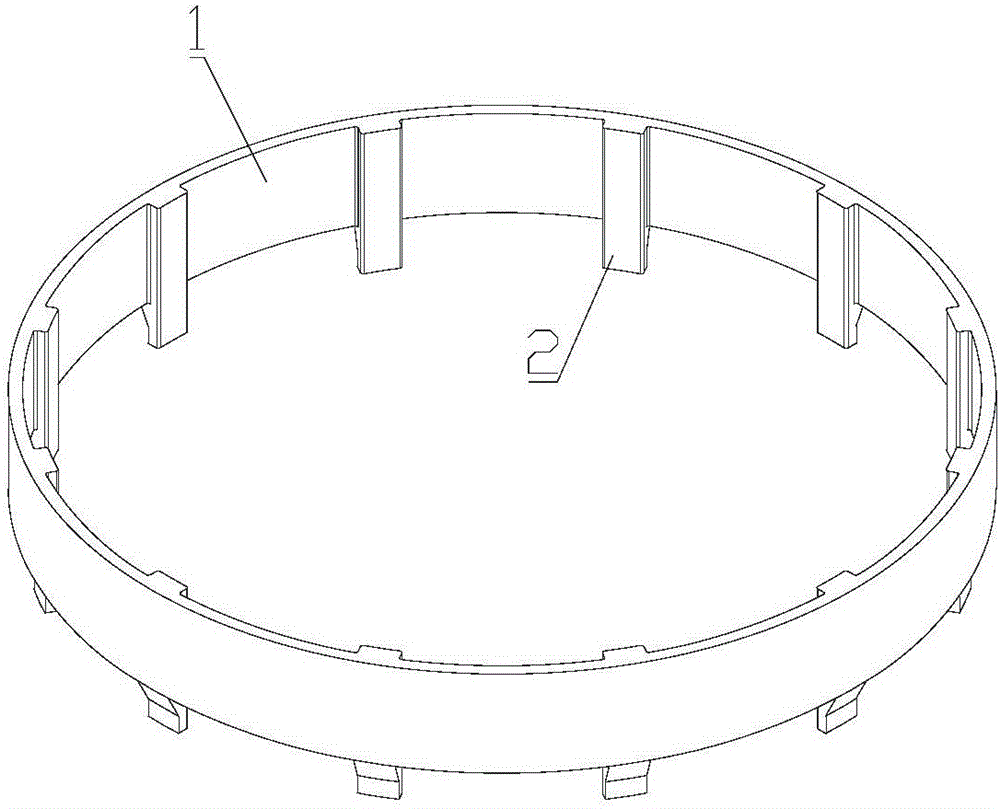

[0028] Please refer to Figure 1 to Figure 7 , the present invention provides a stator holder, which includes a ring body 1 . The outer diameter of the ring body 1 matches the inner diameter of the winding of the stator to be injected, so as to be in contact with the inner wall of the winding during use. Preferably, the stator holder in the present invention can be made of nylon 66 material and 30% glass fiber, which not only increases flexibility, but also has higher rigidity, heat resistance and wear resistance.

[0029] Before injection molding, the stator retainer of the present invention is loaded into the stator coil, so that during the injection molding process, the ring body 1 can not only prevent the winding from being displaced and abnormally deformed, but also avoid the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com