Underground magnetic suspension robot system capable of automatically tracking fault of belt conveyor for coal mine

A belt conveyor and robot system technology, applied in control/regulation systems, instruments, non-electric variable control, etc., can solve the problems of high labor intensity, poor inspection effect, and failure to detect equipment failures in time, so as to improve the detection effect, The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

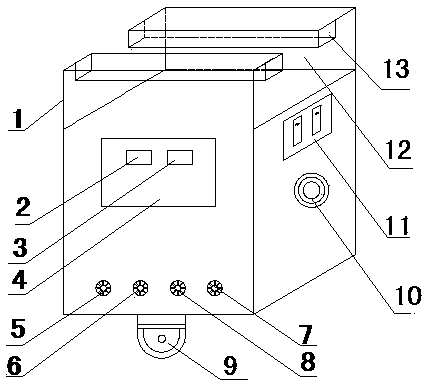

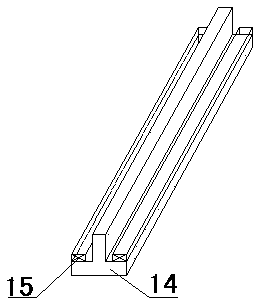

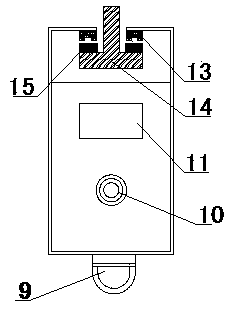

[0022] see Figure 1-6 , a magnetic levitation robot system for automatic fault tracking of underground belt conveyors in coal mines. It consists of electromagnetic guide rails 14, magnetic levitation mobile devices 16, magnetic levitation mobile device wireless charging piles 17 and remote host computers. The electromagnetic guide rails 14 are fixed on the hangers in the belt conveyor lanes. above, corresponding to the position where the conveyor belt needs to be detected; specifically, the electromagnetic guide rail 14 adopts an inverted T-shaped guide rail, and a T-shaped track electromagnetic coil 15 is arranged on the inverted T-shaped guide rail; The upper part is provided with an open slot 12, and the inner surface of the open slot 12 is provided with a magnetic levitation mobile device electromagnetic coil 13 corresponding to the T-shaped track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com