In-series concentrated wound motor public end processing method and motor insulating framework

A technology of insulating frame and processing method, which is applied in the direction of manufacturing motor generators, windings, electrical components, etc., and can solve problems such as limiting motor efficiency, many soldering processes, and inconvenient use of motor common terminal processing methods and insulating frames. Achieve the effects of reducing operators, improving efficiency and improving the reliability of motor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

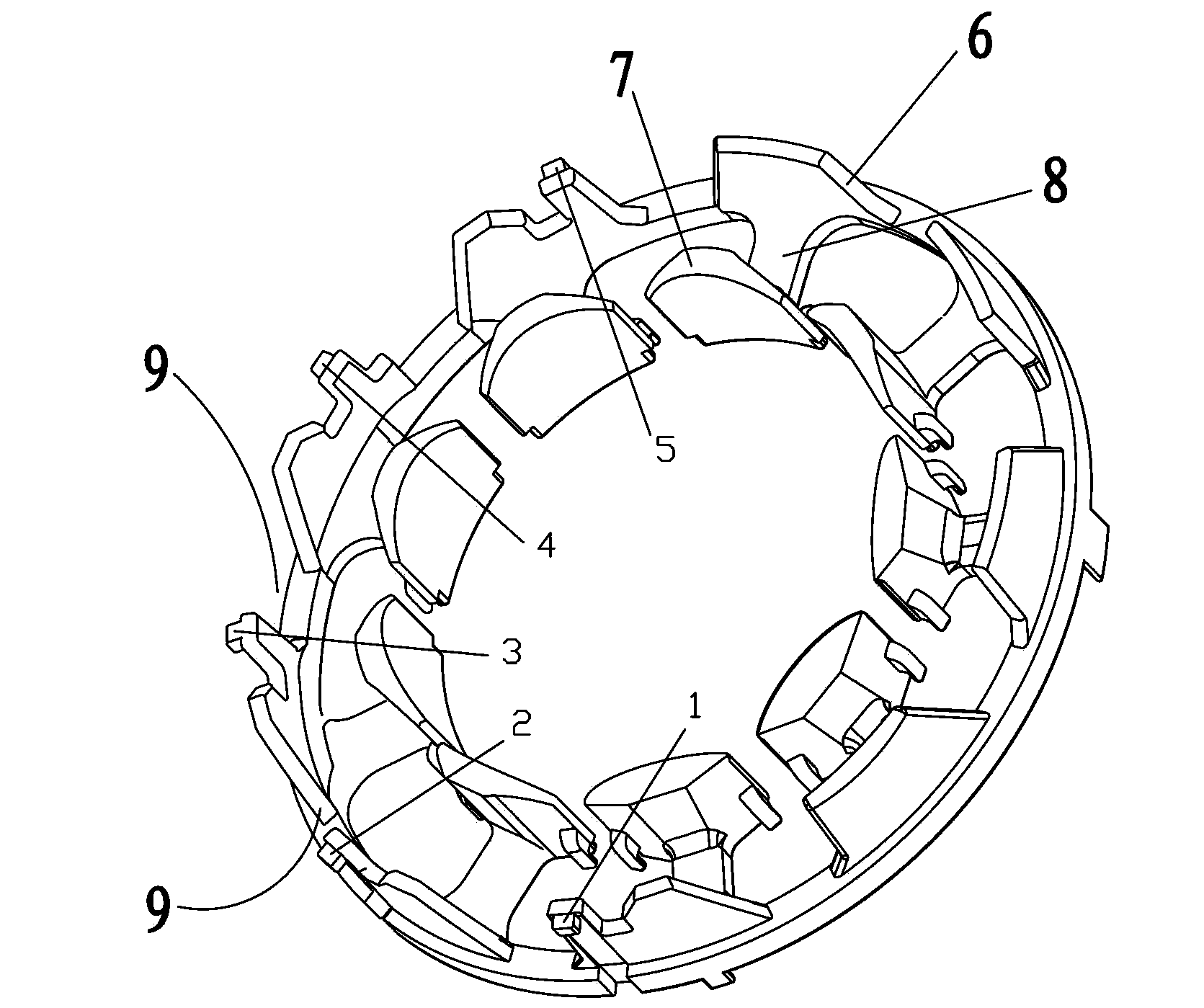

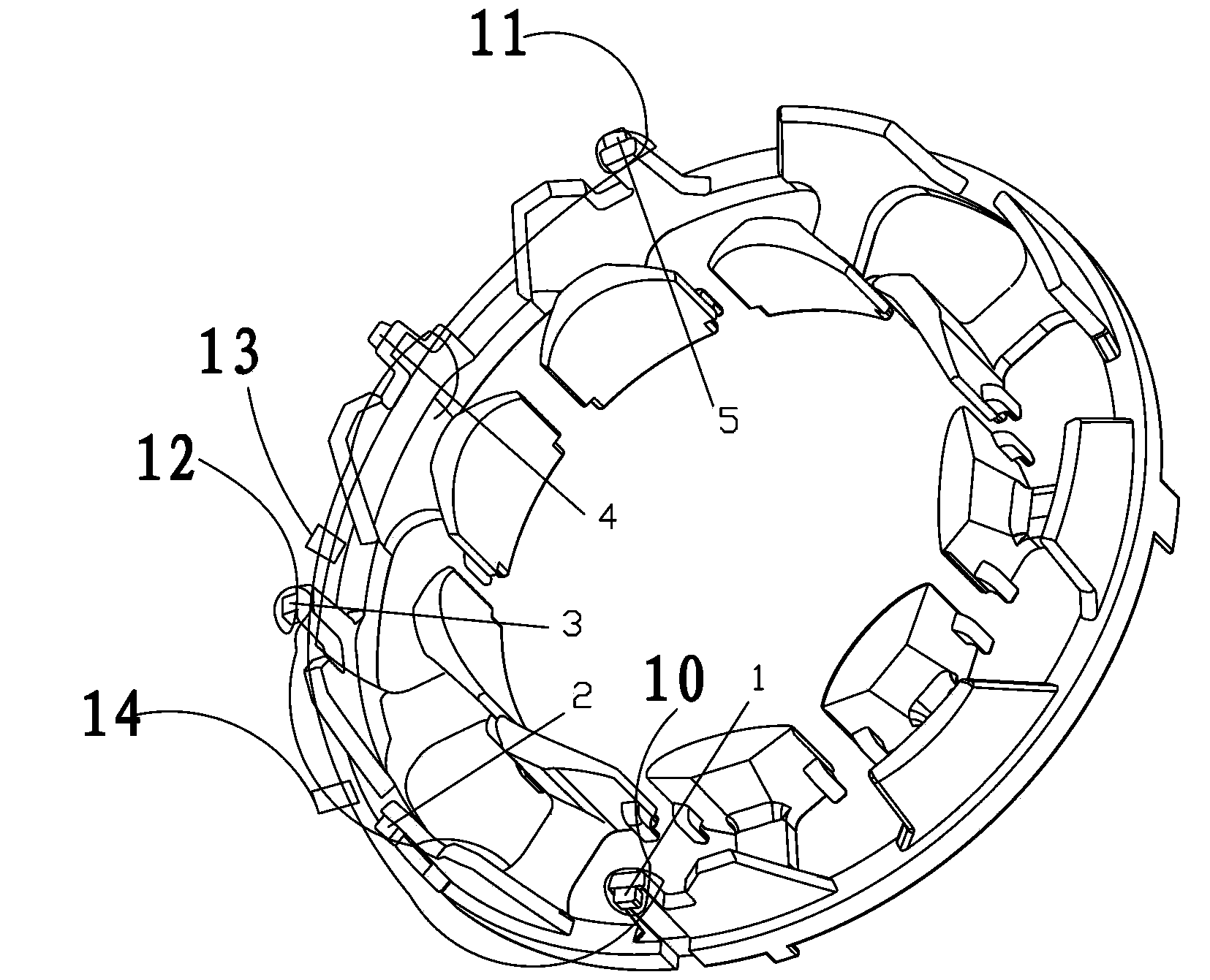

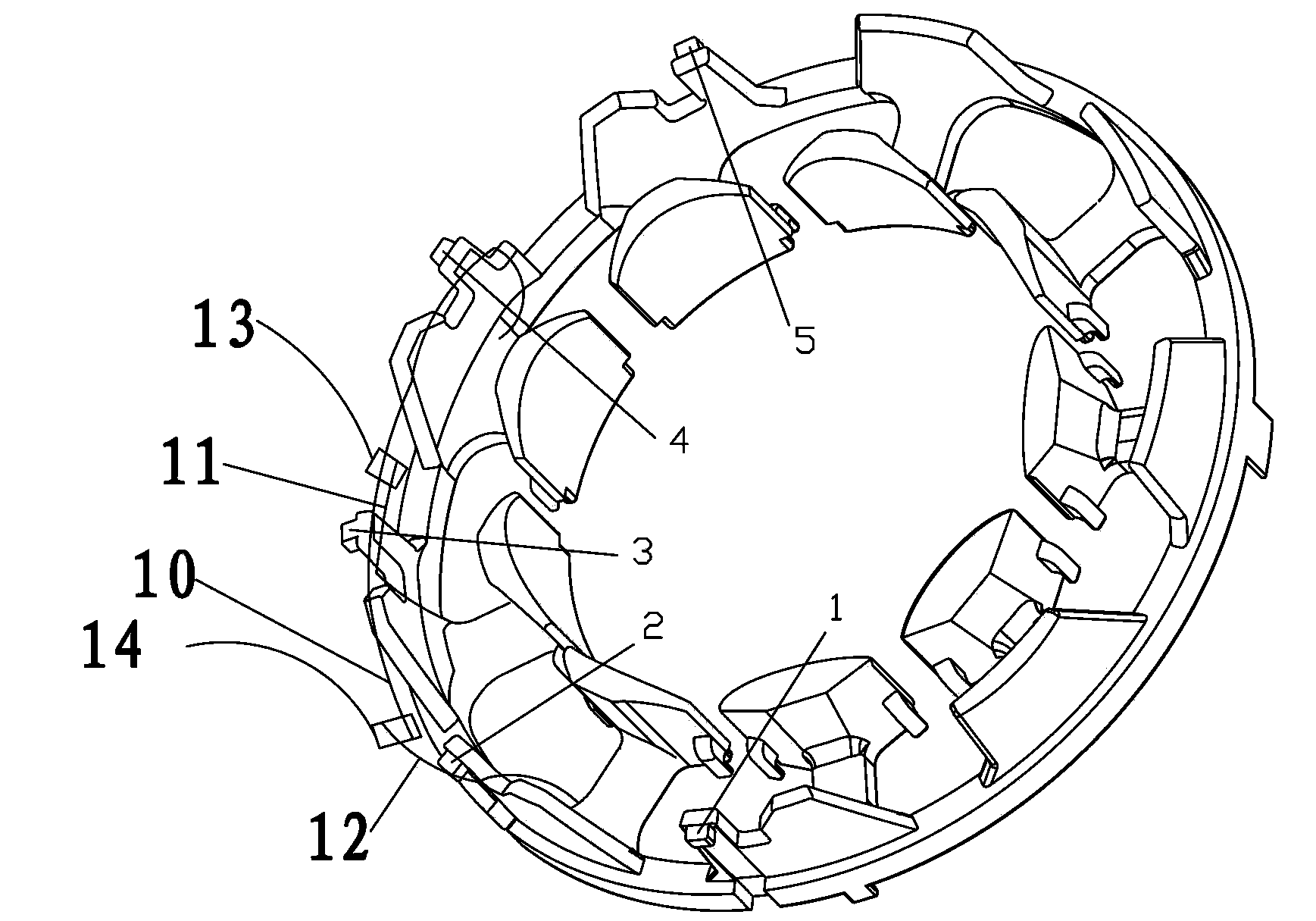

[0038] An embodiment of the motor insulating skeleton of the present invention, as figure 1 shown.

[0039] The insulating frame of the motor of the present invention is a ring structure, used to fix the three-phase winding, including the outer wall 6, the inner wall 7 and the bottom plate 8, the outer wall 6 and the inner wall 7 are connected through the bottom plate 8, The outer wall 6 is provided with a plurality of U-shaped opening slots 9, which are used to place piercing terminals connected by riveting of any two-phase windings in the three-phase windings. The piercing terminals in the prior art can be used, such as Figure 4 shown.

[0040] Between the adjacent open slots 9, there is a boss buckle point, and the boss buckle point is used for positioning any phase winding in the three-phase winding.

[0041] Preferably, as an embodiment, the boss buckle is a cube boss buckle.

[0042] Preferably, as an embodiment, the boss buckle includes a first buckle 1 , a second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com