A furniture table leg solid wood parts dual -end -end -of -cut corner punch punching machine and processing method

A technology of punching machine and solid wood, applied in the direction of wood processing appliances, manufacturing tools, sawing components, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, downsizing and increasing efficiency, etc., to reduce labor intensity, improve production efficiency, reduce The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

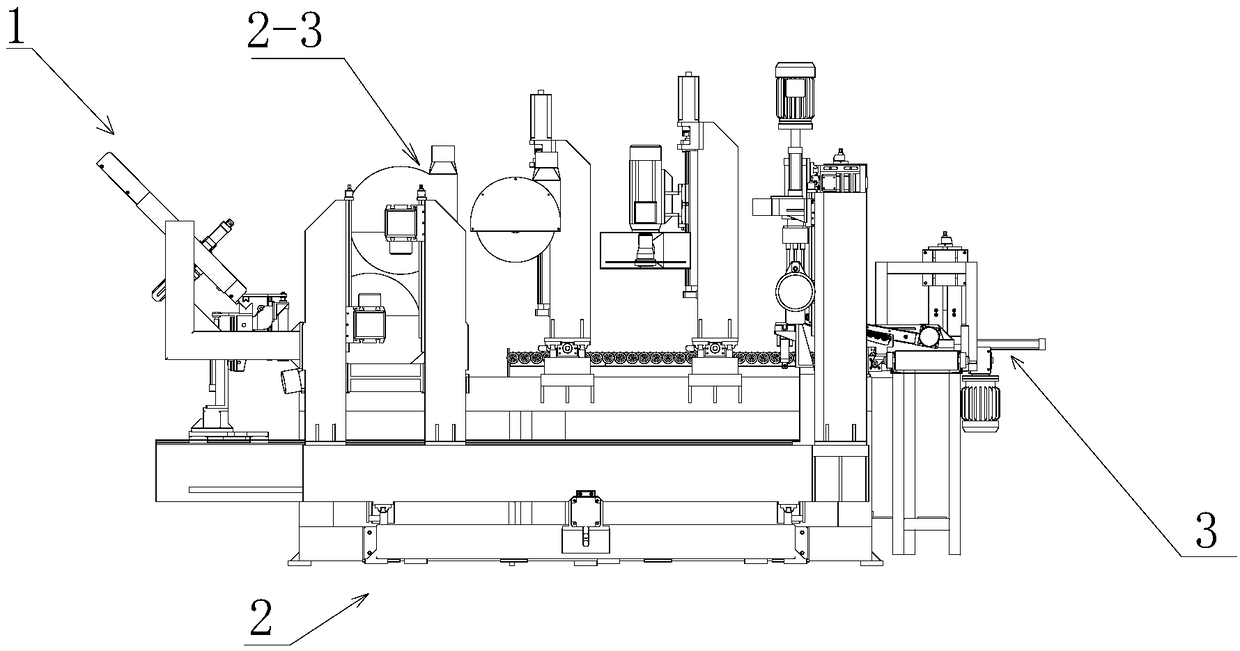

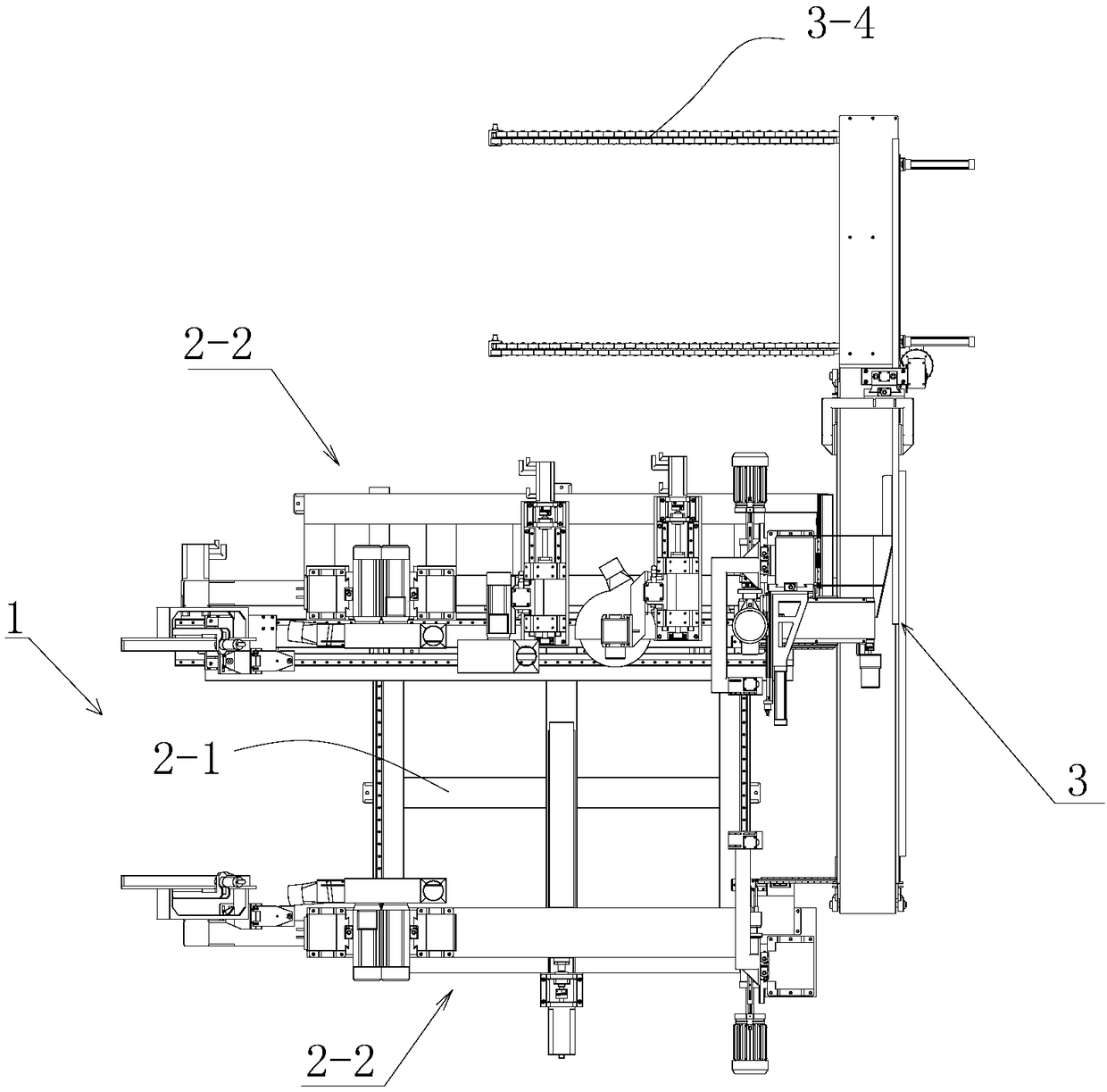

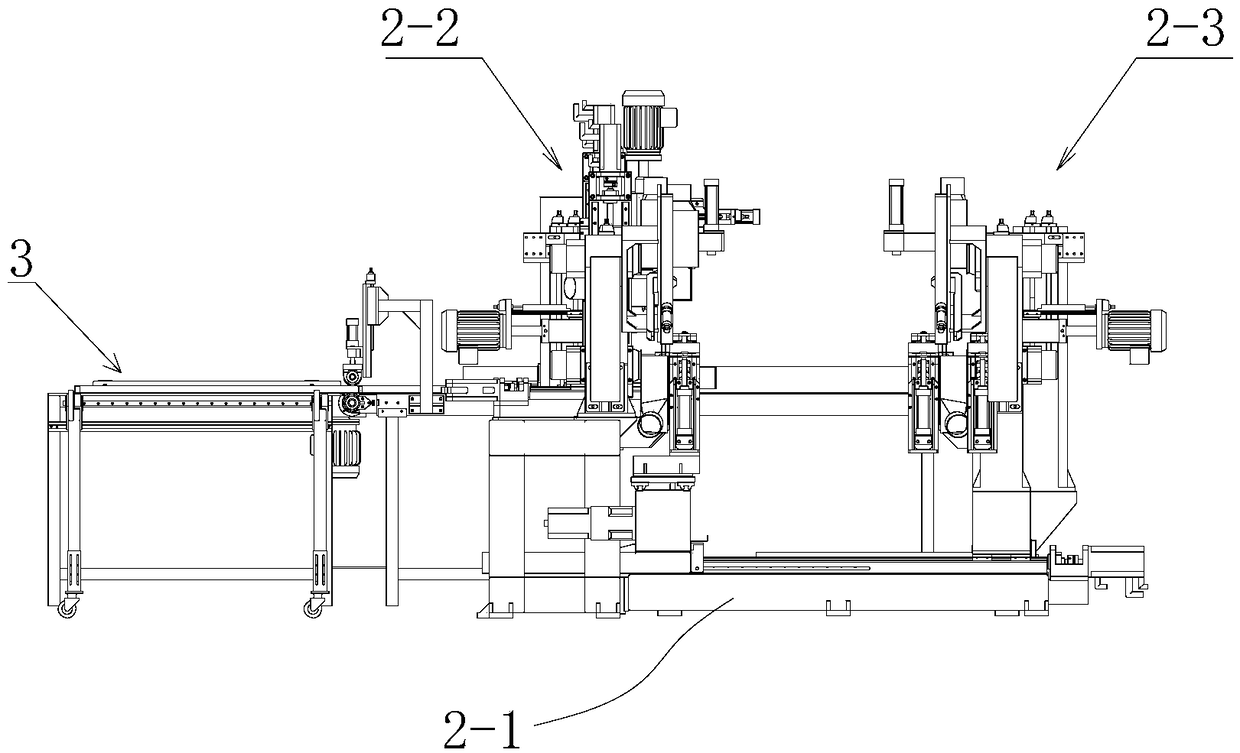

[0036] see Figure 1 to Figure 6 , a double-end fixed-length corner-cutting punching machine for solid wood parts such as furniture table legs, including an upper material bin 1, a fuselage 2, and a finished material conveying mechanism 3; At the discharge end of the fuselage 2, a finished material conveying mechanism 3 is installed; the fuselage 2 includes a machine base 2-1, and a fixed workstation 2-1 is installed on one side of the machine base 2-1 along the material feeding direction. 2. Mobile workstations 2-3 are installed on the other side; the fixed workstations are equivalent to the positioning reference on one side, and are adjusted according to the length of the actual processed solid wood parts; linear slides perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com