Furnace discharging control system for calcium carbide furnace remote control and control method of furnace discharging control system

A technology of remote control and control system, applied in furnace control device, charge control, furnace and other directions, can solve problems such as difficulty, uncertainty, irregular shape of furnace eye, etc., to solve production efficiency, improve safety factor, and reduce control The effect of the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

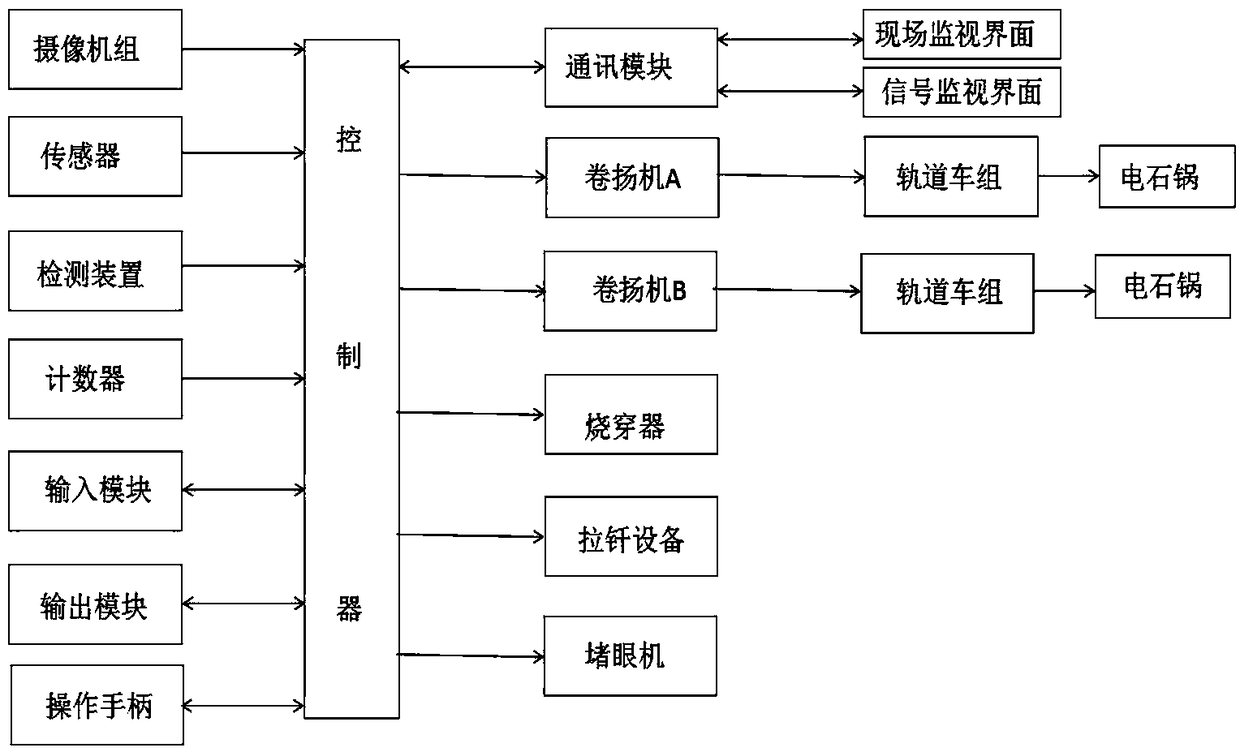

Method used

Image

Examples

Embodiment 1

[0042] Railcar control and operation

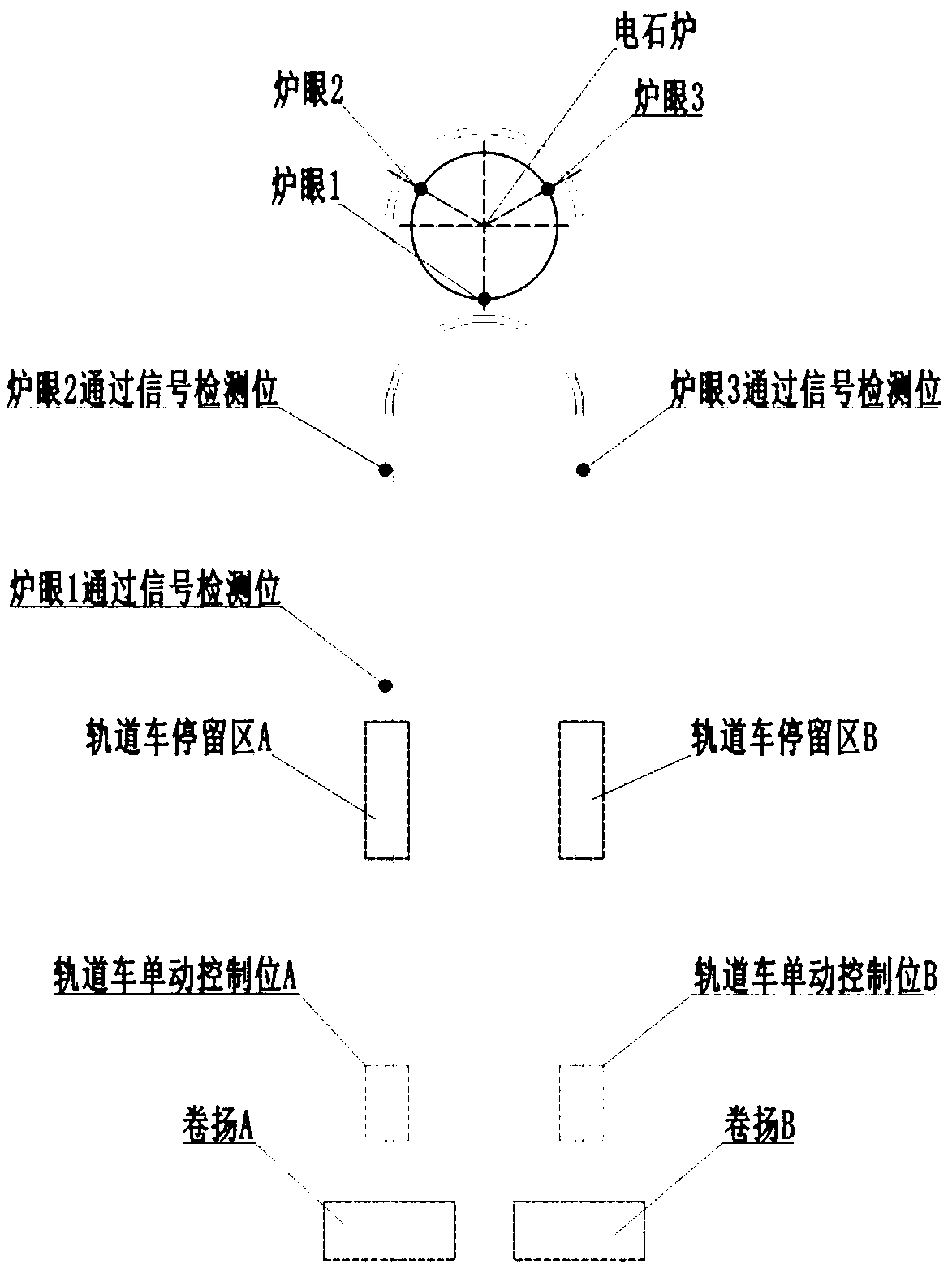

[0043] In this embodiment, the rail car group includes 12 rail cars, each rail car is 1.6 meters long and has three furnace eyes;

[0044] like figure 2 As shown in the figure, a stop signal is set at the stop position of the rail car, and the stop position of the rail car group is set on the track, which are respectively the stop area A and the stop area B; A counter is provided; the number of signal detection bits is equal to the number of furnace eyes; furnace eye 1 corresponds to the signal detection bit of furnace eye 1, furnace eye 2 corresponds to the signal detection bit of furnace eye 2, furnace eye 3 corresponds to furnace eye 3 Take the No. 1 furnace eye as an example, the operation handle executes the rail car No. 1 furnace eye in-position command, the controller uses the sensor to detect the initial position of the rail car group, if the rail car group stays in the "stay area A" ”, the controller controls the clutch switch...

Embodiment 2

[0050] Control and operation of the furnace

[0051] When the controller receives the signal of "the No. 1 furnace eye of the rail car is in place", the controller unlocks the control components such as various function buttons and handles of the furnace that operate the No. 1 furnace eye.

[0052] After the controller receives the signal that the rail car is in place, it sets the zero position in the input module in advance, and controls the operating handle to make the burn-through move forward and backward by observing the burn-through on-site monitoring interface and signal monitoring interface to find the burn-through device. The zero position in the forward and backward direction, when the burn-through device reaches the zero position, the sensor will give a signal. After the controller receives the signal, the burn-through device zero indicator on the output module will be on.

[0053] The controller controls the burn-through device to be connected to the power supply. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com