Self-service automobile loading system and method for coal mine

A self-service, automotive technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of large accuracy deviation, large consumption of manpower and material resources, and inability to meet the requirements of trade settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

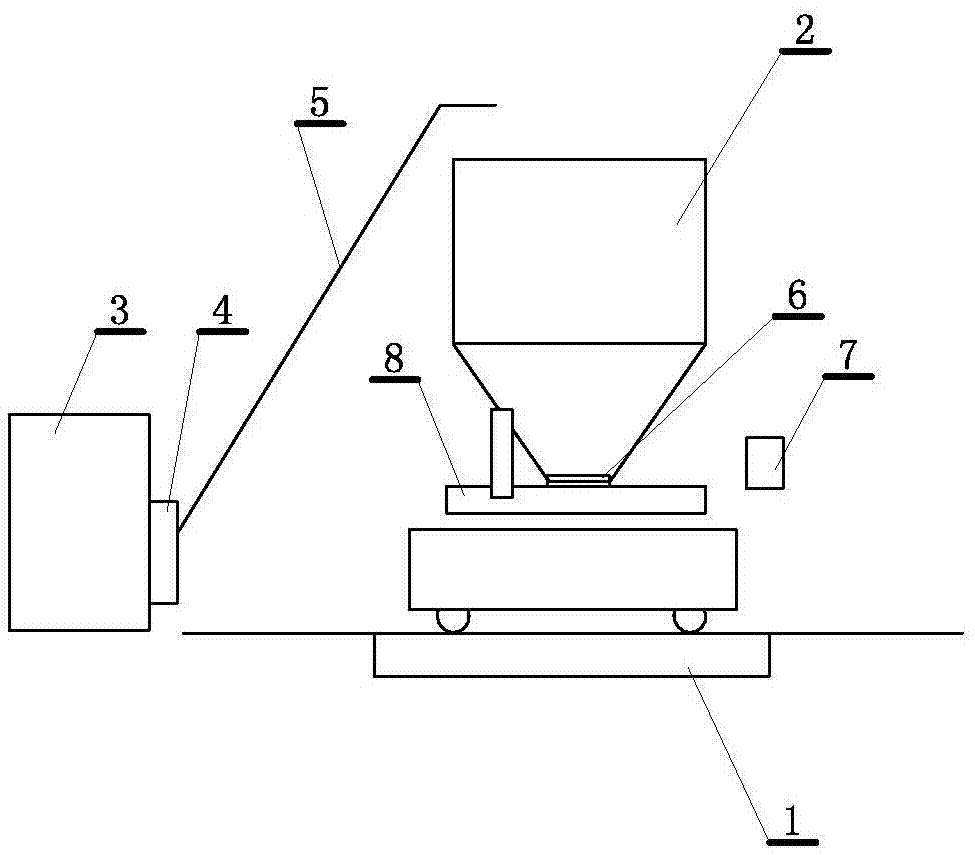

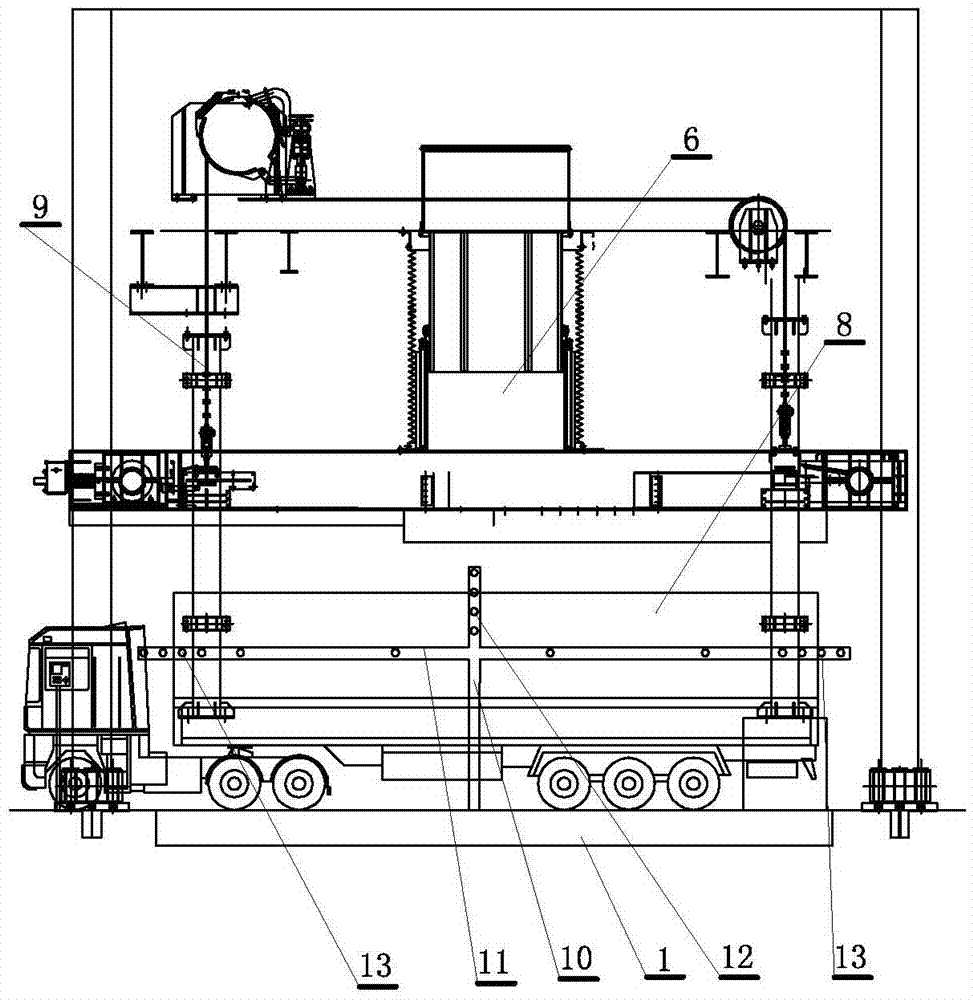

[0027] A coal mine self-service car loading system, such as figure 1 and figure 2 As shown, it includes a weighing truck scale 1 set on the ground, wherein the weighing truck scale is an electronic weighing scale, and a storage bin 2 is arranged above the weighing truck scale to store materials The feeder 4 of the bin is connected to the feeder 4 of the washing center 3 through a conveyor belt 5, and the discharge port of the storage bin is provided with a discharge gate 6, and a control valve is also provided above the weighing truck scale through a suspension mechanism. Controller box 7, the controller box is provided with operation keys, a system server (not shown) is connected to the control circuit in the weighing truck scale and the controller box respectively, and the system server is connected and controlled through a PLC controller (not shown) Unloading gate.

[0028] Through the above system, the driver drives an empty car to the truck weighing platform below the ...

Embodiment 2

[0036] A coal mine self-service car loading method is a self-service car loading method based on the coal mine self-service car loading system described in embodiment 1, and the content in embodiment 1 should also be regarded as the content in this embodiment, so , the system includes an electronic weighing truck scale set on the ground, a storage bin is arranged above the weighing truck scale, and the feeding port of the storage bin is connected with the feeder of the washing center through a conveyor belt , the discharge port of the storage bin is provided with a discharge gate, and a controller box is also provided through the suspension mechanism above the weighing truck scale. The controller box is provided with operation buttons, and a system server is respectively connected to the weighing truck scale. And the control circuit in the controller box, the storage bin is provided with a bin capacity sensor, the bin capacity sensor signal is connected to the system server thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com