Ceramic granite tower circulating water treatment system, circuit and pH value control method

A treatment system and a granite tower technology are applied in the field of the treatment system of the circulating water of the ceramic granite tower, which can solve the problems of affecting the pH value of the circulating water, affecting the desulfurization effect of the granite tower, and detecting errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

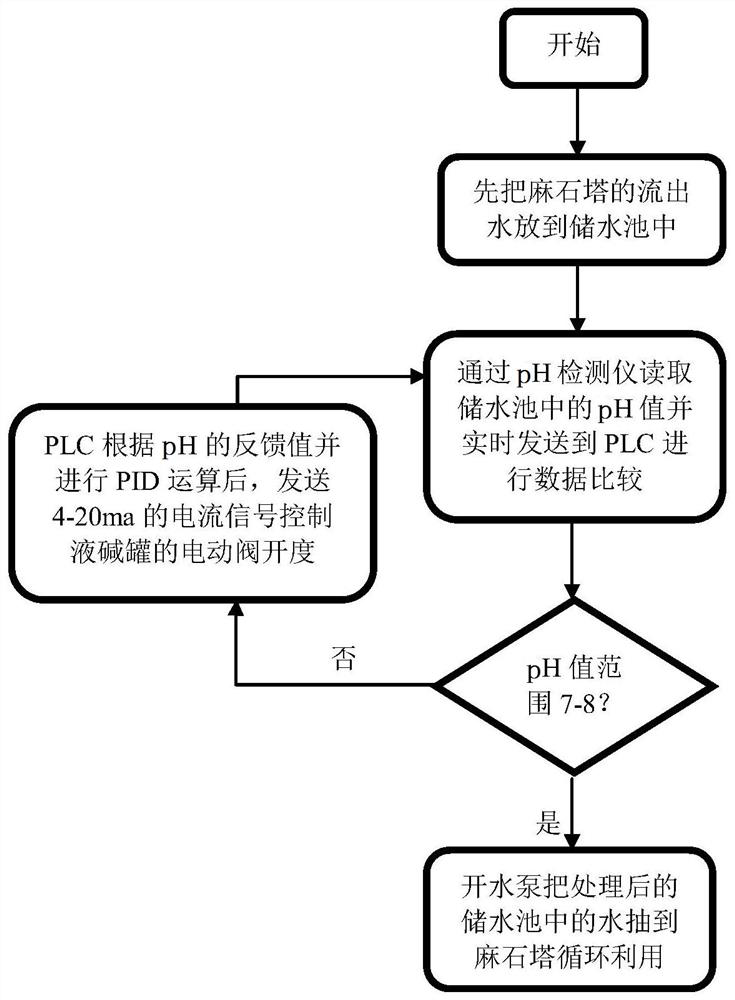

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing:

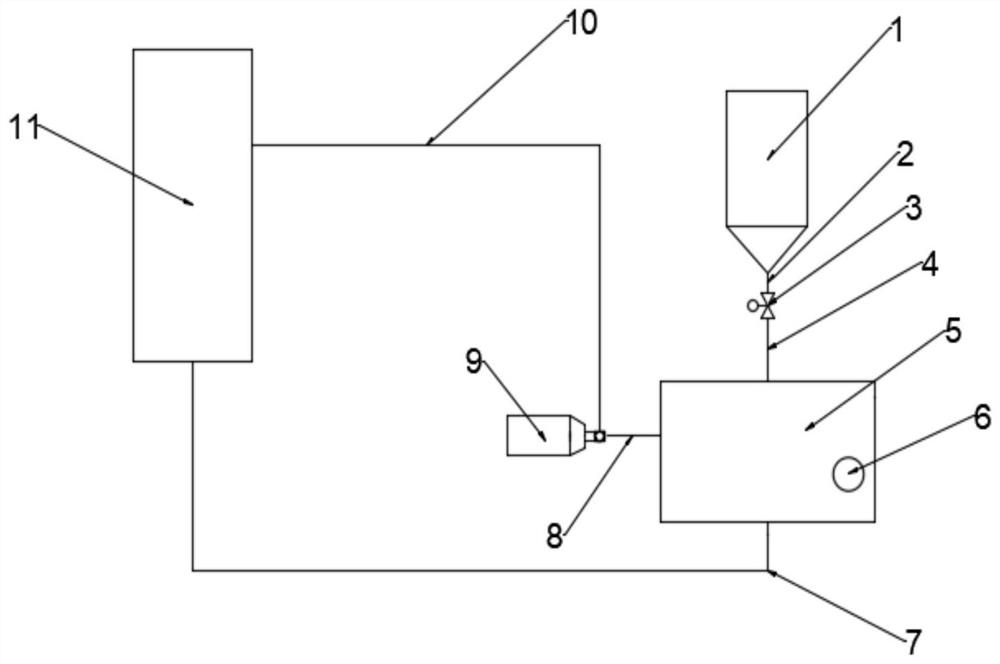

[0035] see figure 1 As shown, it is used in the treatment system of stone tower circulating water in the ceramic industry. The stone tower 11 in the system is connected to the water storage tank 5 through the third pipeline 7. The water storage tank 5 is equipped with a pH detector 6, and the water storage tank 5 is divided into two ways: One way connects the water pump 9 through the fourth pipeline 8, and the water pump 9 returns to the stone tower 11 through the fifth pipeline 10 to form a closed loop, and the other way connects the electric valve 3 and the liquid alkali storage tank 1 successively through the second pipeline 4; Including electrical control circuit.

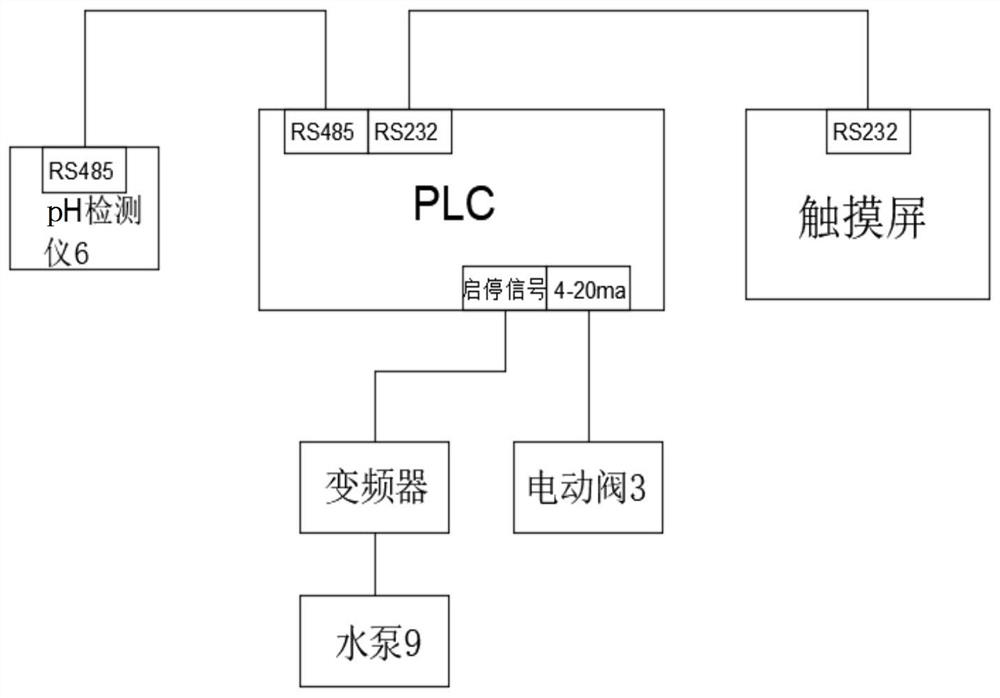

[0036] see figure 2 As shown, the electrical control circuit includes a PLC controller, a pH detector, a touch screen, an electric valve, a frequency converter, and a water pump; the PLC controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com