Coal mining machine coal mining control method with automatic coal cutting being primary and remote interference being auxiliary

A control method and shearer technology, applied in the field of shearer control, can solve the problems of harsh working environment, low degree of mechanization, and high labor intensity for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

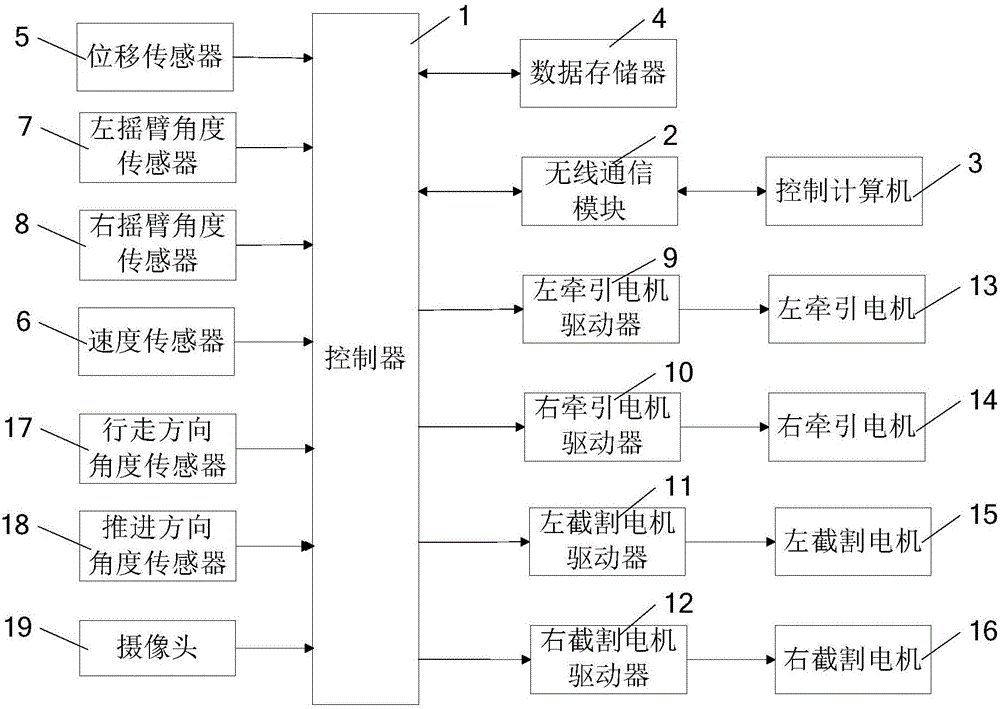

[0057] In the present invention, the coal cutting control method for a shearer is mainly based on automatic coal cutting and supplemented by remote intervention. The shearer is a double-drum shearer. The left walking box at the lower left of the shearer fuselage and the right walking box installed at the lower right of the shearer fuselage, as well as the left rocker arm hinged on the left side of the shearer fuselage through the hinge shaft and the The right rocker arm on the right side of the coal machine body, the left running box is driven by the left traction motor 13, the right running box is driven by the right running motor, the front end of the left rocker arm is installed with a left drum, and the left drum is The left cutting motor 15 is driven, the front end of the right rocker arm is installed with a right drum, and the right drum is driven by the right cutting motor 16; such as figure 1 As shown, the control system adopted by the method comprises a controller 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com