Self-propelled storage battery tractor

A technology for tractors and batteries, which is applied in the field of battery tractors for logistics distribution and automatic driving logistics distribution equipment, which can solve the problems of long working distance, high labor intensity for drivers, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

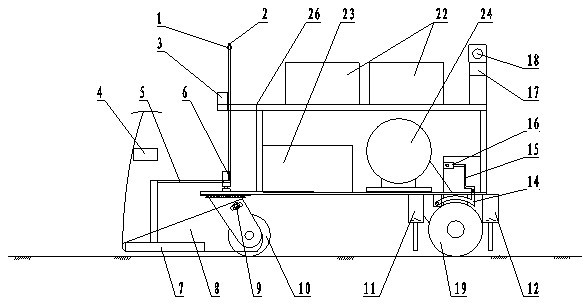

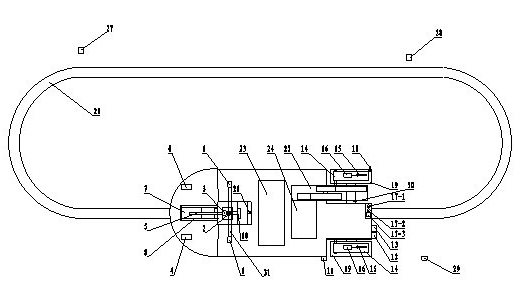

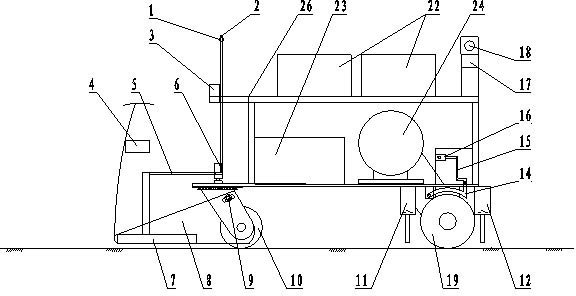

[0016] Referring to Fig. 1 and Fig. 2, the composition of the present invention includes a driving system, a control system and a drive system. Described traveling system comprises vehicle frame 26, handle 2, screw rod 6, direction connecting rod 5, magnet 7, magnet bracket 8, universal wheel assembly 10, rear wheel 19, connecting rod 15 and brake pad 14; 26 is a truss structure, the handle 2 and the screw 6 form a screw transmission pair, the screw 6 is vertically installed on the ground, and its lower end is connected to the rear end of the direction link 5, and the directional link 5 is a fulcrum fixed on the front end of the car body The lever mechanism, when it is in the natural state, the front end overlaps with the magnet 7, the magnet 7 is located on the magnet bracket 8, the magnet bracket 8 is provided with an adjusting screw 9, the magnet bracket 8 is fixed on the universal wheel shaft, The universal wheel assembly 10 is installed in the middle of the front part und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com