Storage and distribution device for pallets

A technology of distribution device and platen, which is used in transportation and packaging, conveyor objects, destacking of objects, etc., can solve the problems of heavy workload, failure to reduce staff and increase efficiency, and failure to meet automation, and improve efficiency. and quality, to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments.

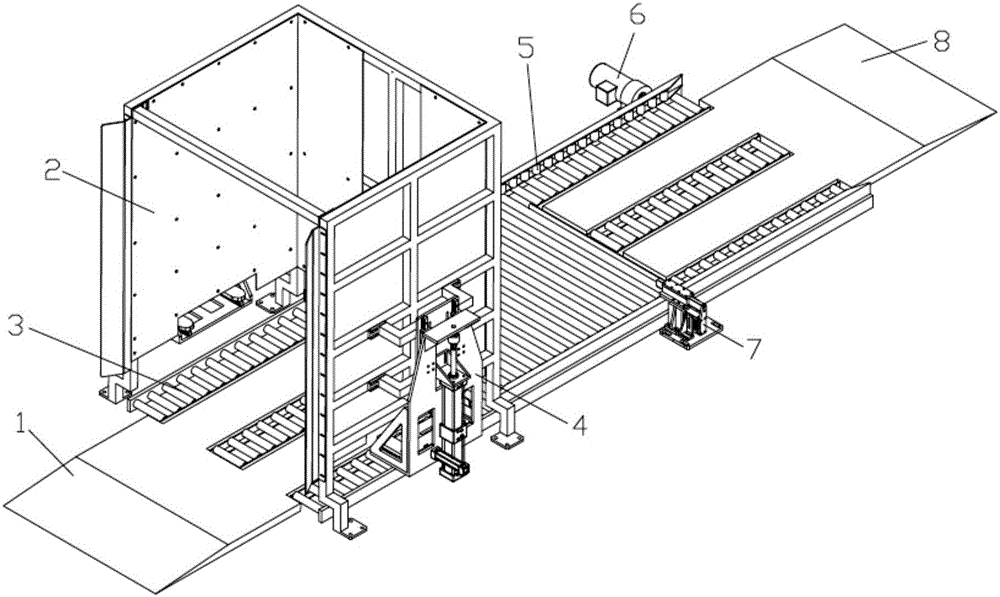

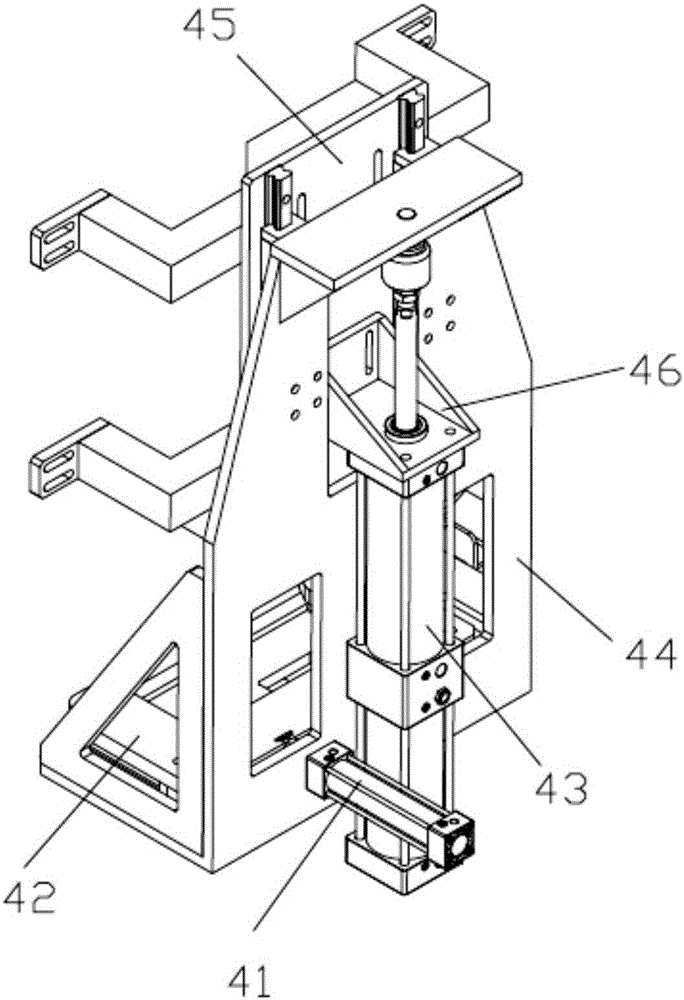

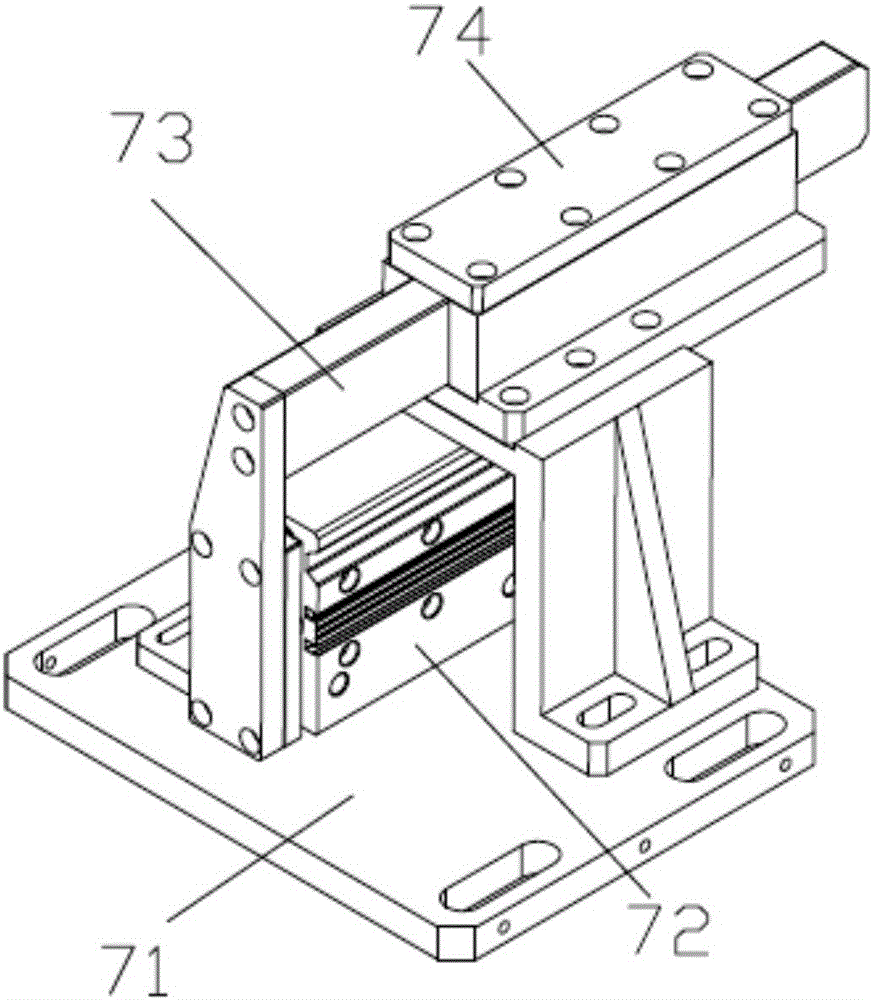

[0022] The floor board storage and distribution device of the present invention, such as figure 1 As shown, the bottom plate is included. The bottom plate is provided with a floor plate storage frame 2. When in use, the stacked floor plates are transported and placed in the floor plate storage frame 2, on both sides of the floor plate storage frame 2. It is provided with a lifting mechanism 4 that can lift up the rest of the floor plates except the bottommost floor plate each time, and the floor plate at the bottom end can be transported forward along with the conveying roller provided on the bottom plate. When the floor board needs to be output, the lifting mechanism 4 starts to lift the upper floor board, and starts the conveying motor that controls the rotation of the conveying roller. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com