Method for predicting mechanical strength and thermal properties of coke

A technology of mechanical strength and thermal properties, applied in the field of coal chemical industry, can solve problems such as inaccurate prediction of coal quality indicators, and achieve the effects of overcoming inaccurate prediction of coke quality, reducing coal blending costs, and accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

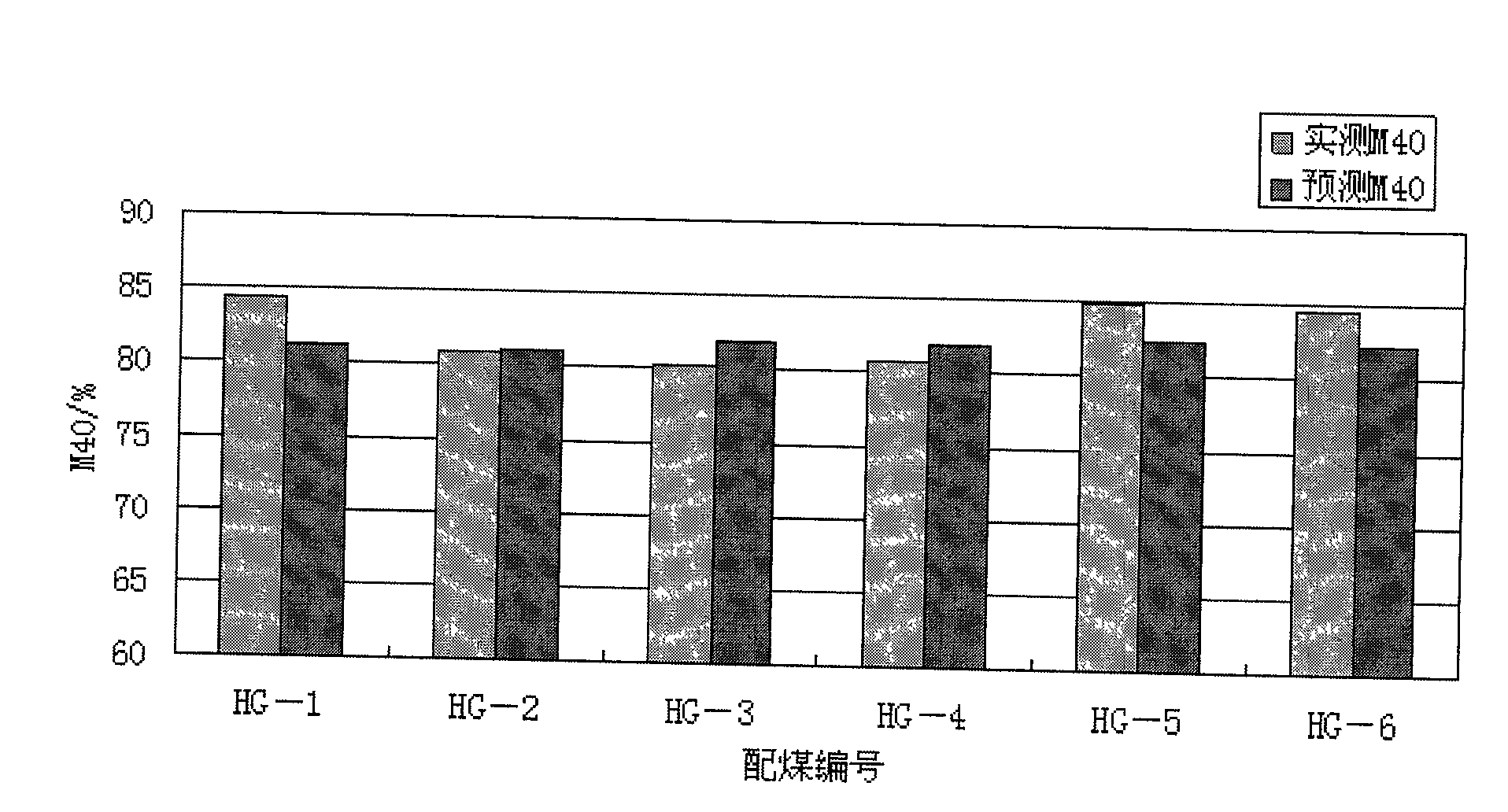

[0045] A method for predicting the mechanical strength and thermal properties of coke. The method uses the reflectance distribution of vitrinite as the main input parameter to predict the mechanical strength index and thermal property index of coke.

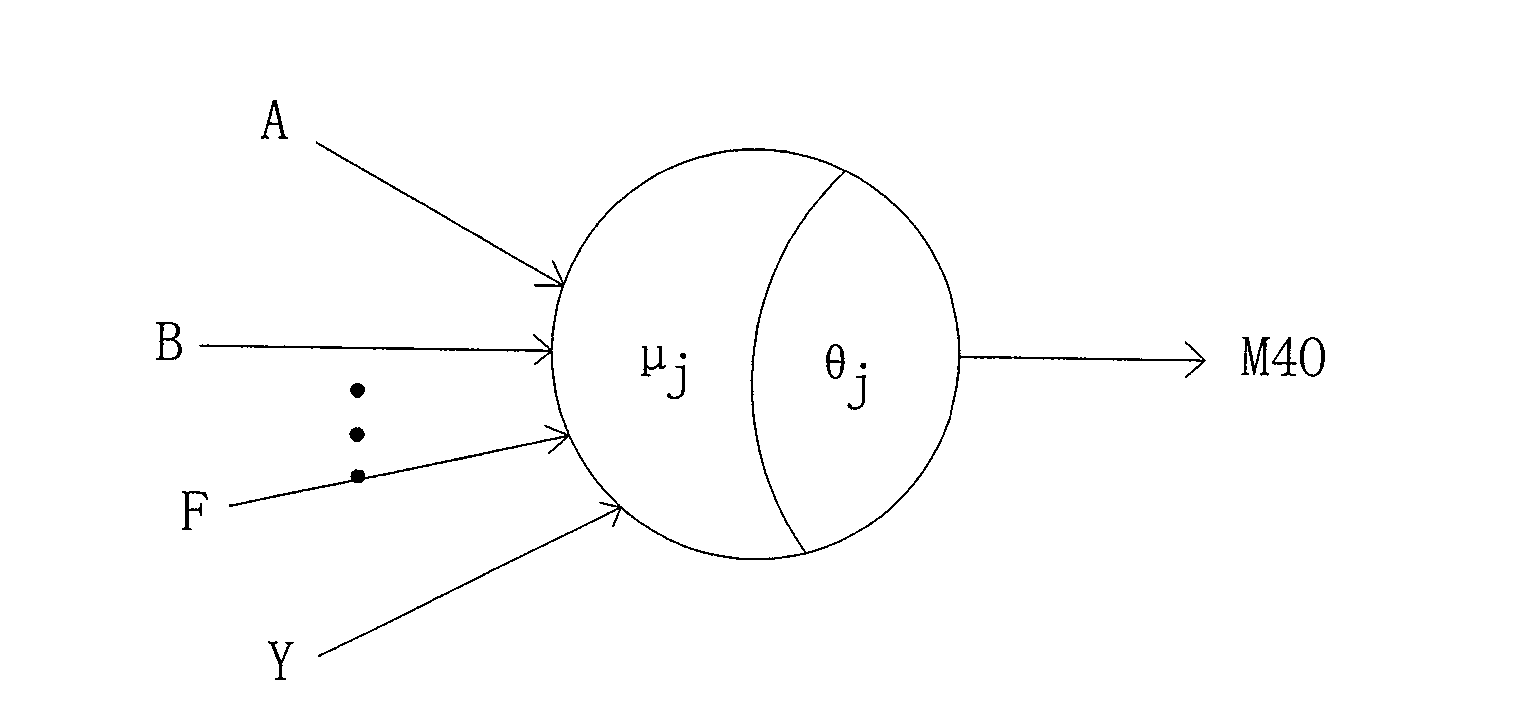

[0046] 1. Prediction of coke mechanical strength index is realized through BP neural network; coke mechanical strength index includes crushing strength (M 40 ) and abrasion resistance (M 10 ), which is related to the metamorphic degree and caking property of coal. The present invention uses vitrinite reflectance distribution and cohesiveness index (such as cohesive index G, colloidal layer maximum thickness Y) as parameters, and predicts coke mechanical strength through BP neural network.

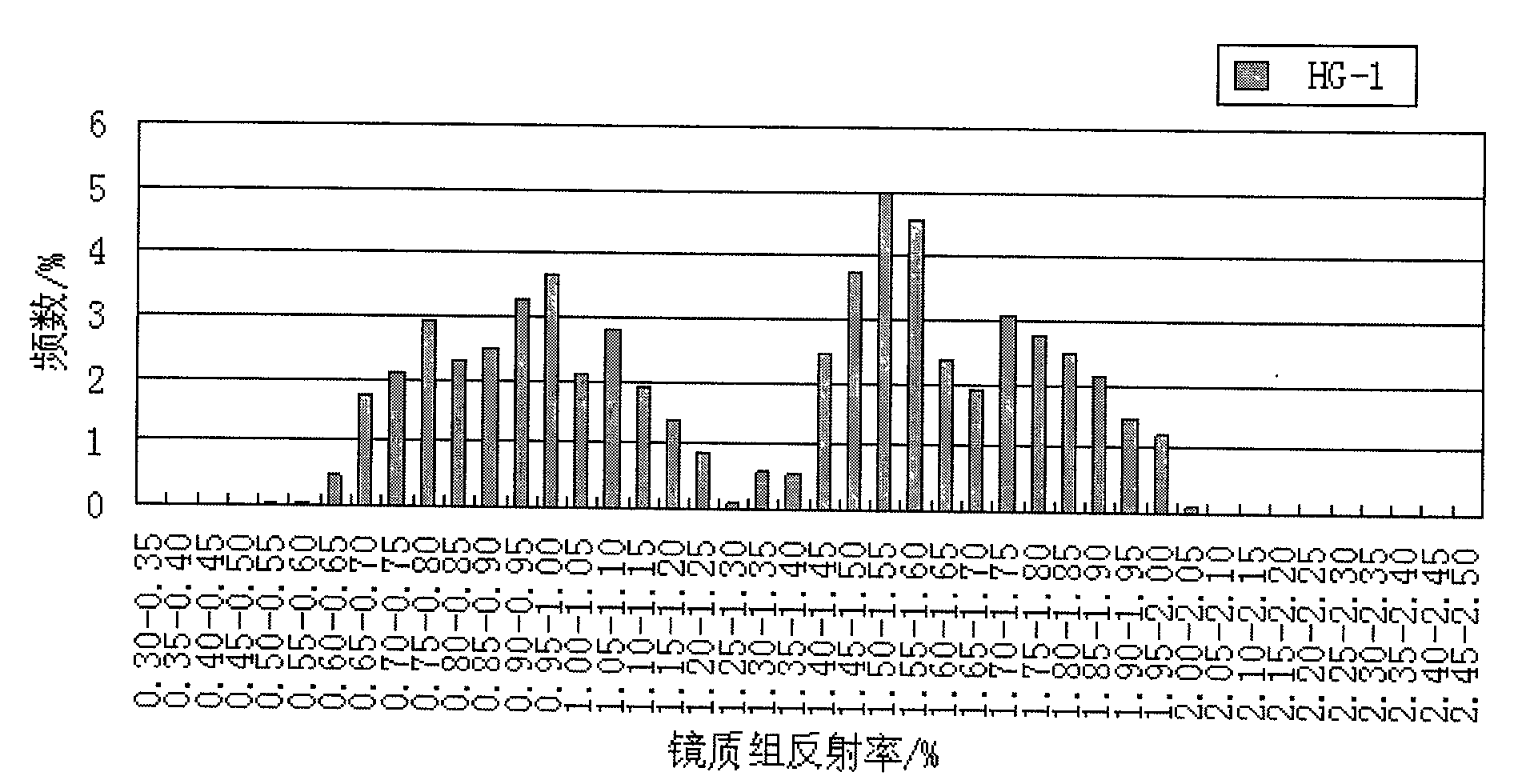

[0047] The vitrinite reflectance of a large number of representative coals in the historical production data is divided into six segments (A, B, C, D, E, F) (see Appendix 1 for the division method of vitrinite reflectance). The cohesiveness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com